Page ‑ 3

Manual | English

1. General remarks:

IMPORTANT !

The SUPER JIB I may only be installed/deinstalled and operated accor‑

ding to the operating instructions.

The operating instructions must have been read and understood

• The SUPER JIB I may only be used by trained personnel.

• Only Panther EVOLUTION, CLASSIC or SUPER PANTHER III dollies with corresponding soft‑

ware for SUPER JIB II may be used (market on electronics: SUPER JIB SJ).

• No pneumatic wheels may used on the dolly in connection with SUPER JIB I.

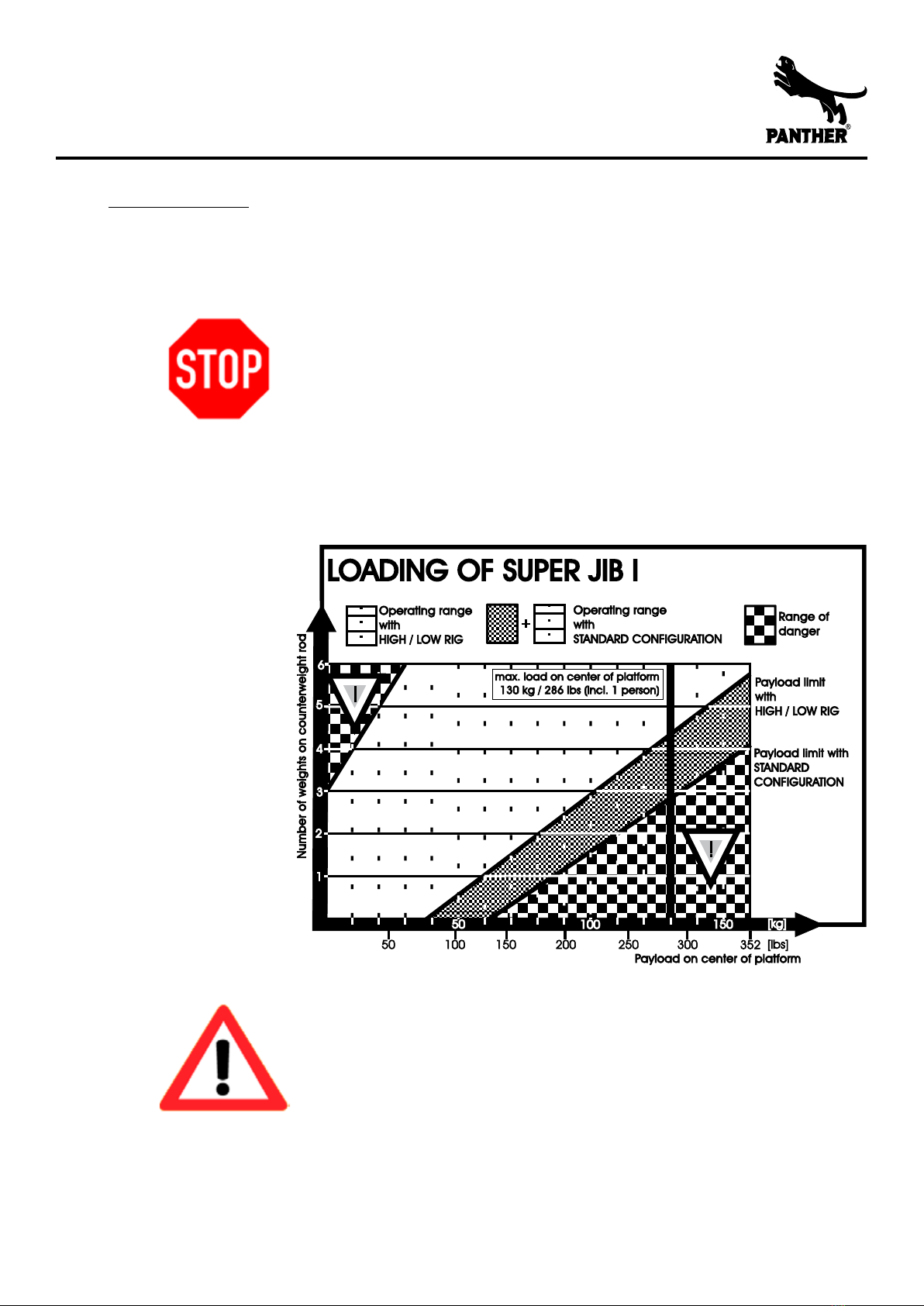

• The loading diagram must be observed.

• In any case, before commissioning of SUPER JIB I, steadiness must again be tested using

the maximum pitching moment to be expected.

• The horizontal and vertical field of traverse of SUPER JIB I must in any case be kept free.

• Use of the Panther Steer out Extention (Code no. 123915 for Evolution/Classic or Code no.

100507 for Super Panther 3) is recommended

• Do only use Panther original accessories

• Combined seat extensions (vertical/horizontal) with the order numbers 110, 111, 112,

105663, 105662, 105661 must not be used. Use only vertical seat extensions or combined

seat extensions marked with “HD” (=heavy duty).

• take care, that during installation and operation there is an absolutely hard, inflexible

underground, which is absolutely smooth and level. No inclined plane!

• Maximum wind during operation: 40 km/h

• during studio and rail operation, it must be taken care that no hard or loose objects can

be rolled over. Even small spots of unevenness may endanger secure standing and dri‑

ving. Do not use pneumatic wheels!

• Swing out all 4 wheel arms. Make sure that the locking bolts of the wheel arms are lo‑

cked.

• The sequence of installation and loading instructions must be observed in any case.

• SUPER JIB I may only be installed in the variants shown within these operating instruc‑

tions.

• Take care, that the platform height may never exceed 3 m / 9‘10“ from ground (that

means you may never swing out the outrigger e.g. outside a window or over the railing

of a bridge. The underlay of tracks must be choosen that the max. height of the platform

may not exceed 3 m / 9‘10“.