Steering rod

The steering rod steers and pushes the

Panther Buddy.

It should not be used as seat or standing

area. The ergonomic steering crown will

accept the handset control.

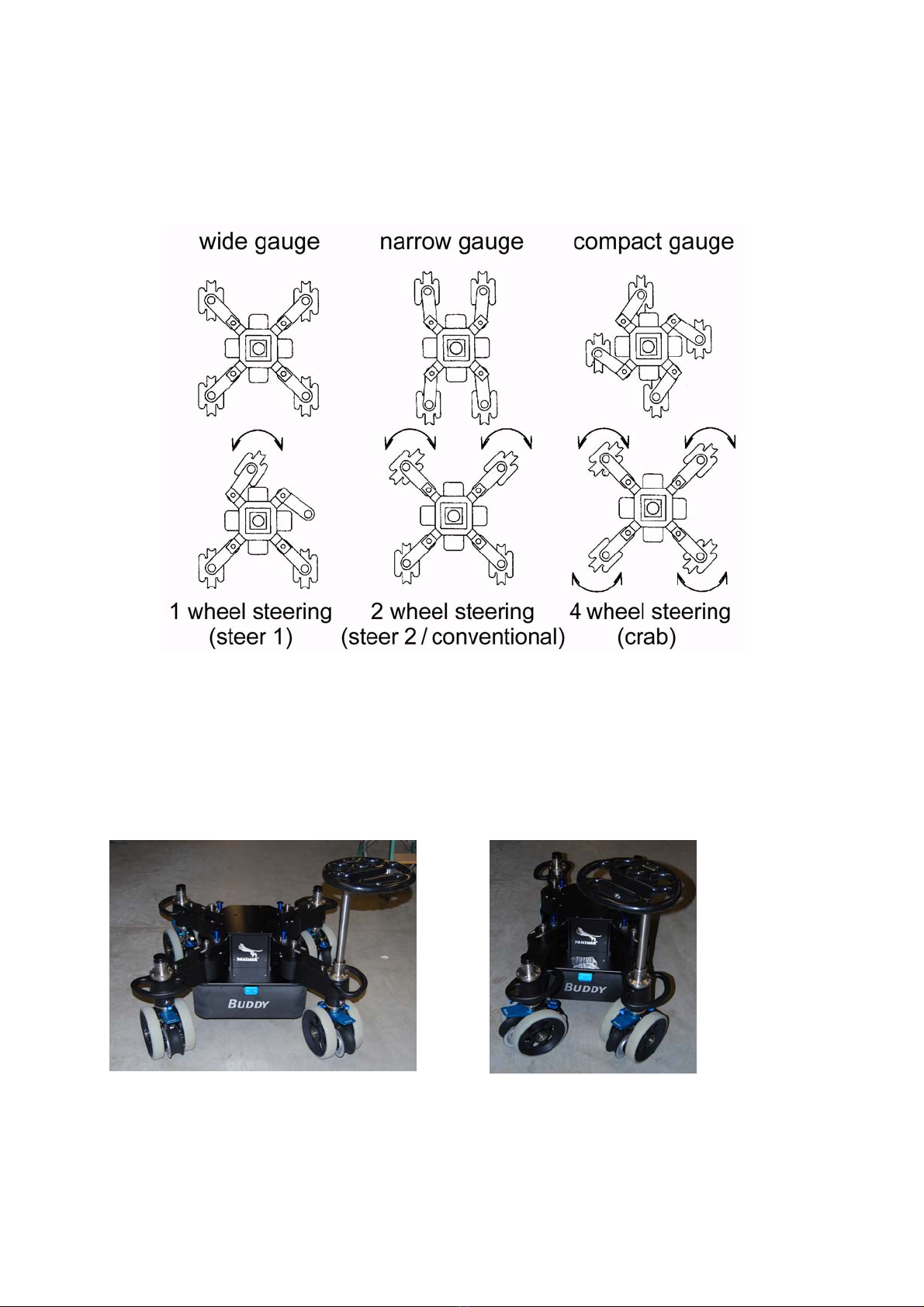

The Panther Buddy dolly has a ,,Crab’’ +

,,Steer’’ operation system.

This ,,Crab’’ (4-wheel) und ,,Steer’’ (2-

wheel) steering is made possible with quick

and unproblematic switching by hand.

The gauge-stable steering geometry of the Panther Buddy dolly was made possible

by a patented shiftbox. A steerage transmission rod or wheel locking bar is now

unnecessary.

Switching over from ,,Crab’’ to ,,Steer’’.

Switching over is possible when the

Kombi Wheels are in starting position

(see pic.), i. e. in direction of movement.

The switching operation should be

supported by lightly moving the steering

rod in a left/right direction.

„Crab“ can be effected from all four

wheel arms, whereas „Steer“ can only be

effected from the two wheel arms on the

side of blue swiching lever (operating

side).

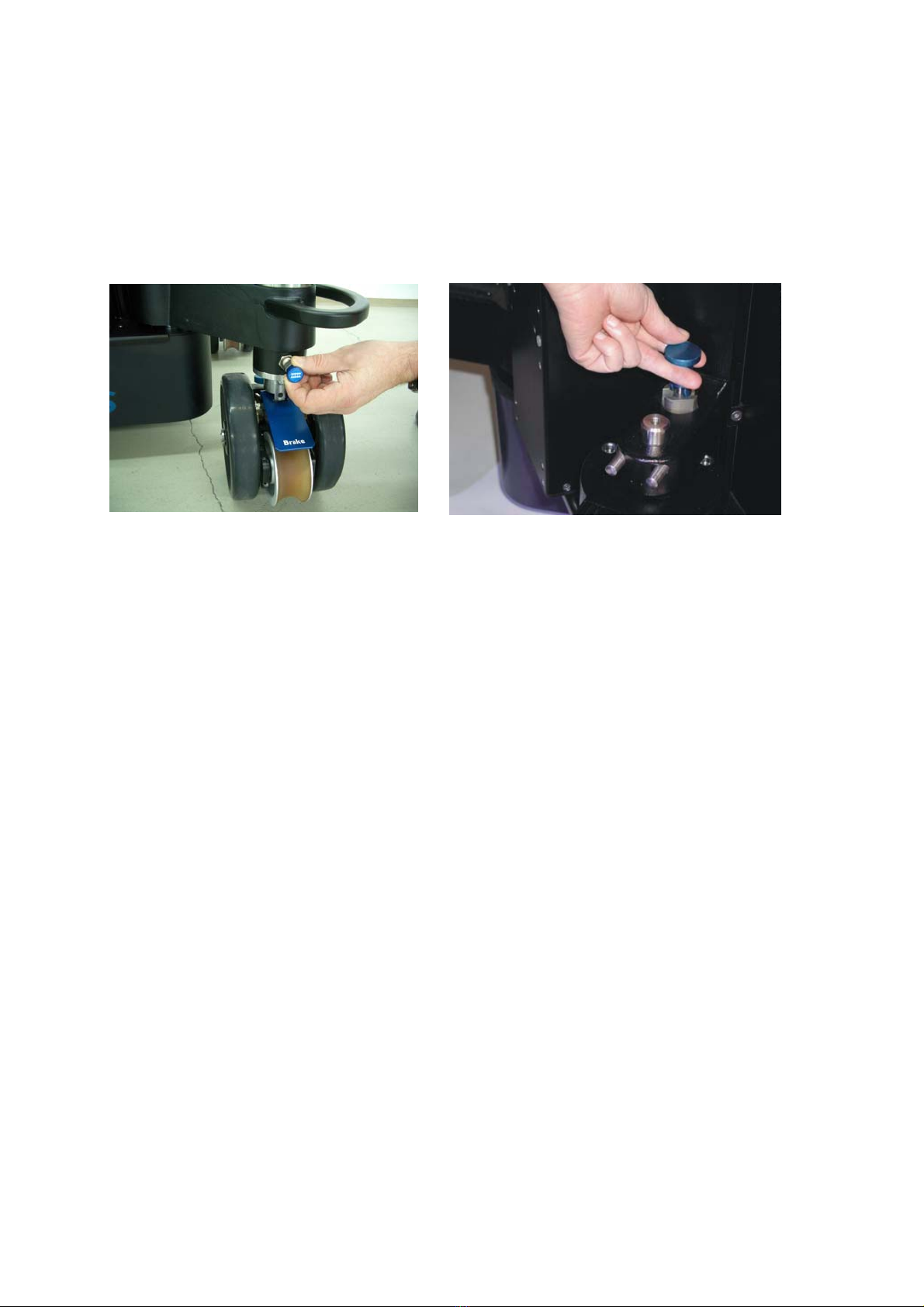

Attention:

If the dolly has a heavy load and/or is equipped with air tires, two-wheel steering is

not to be recommended due to higher static friction, as very large steering forces are

necessary.

Note:

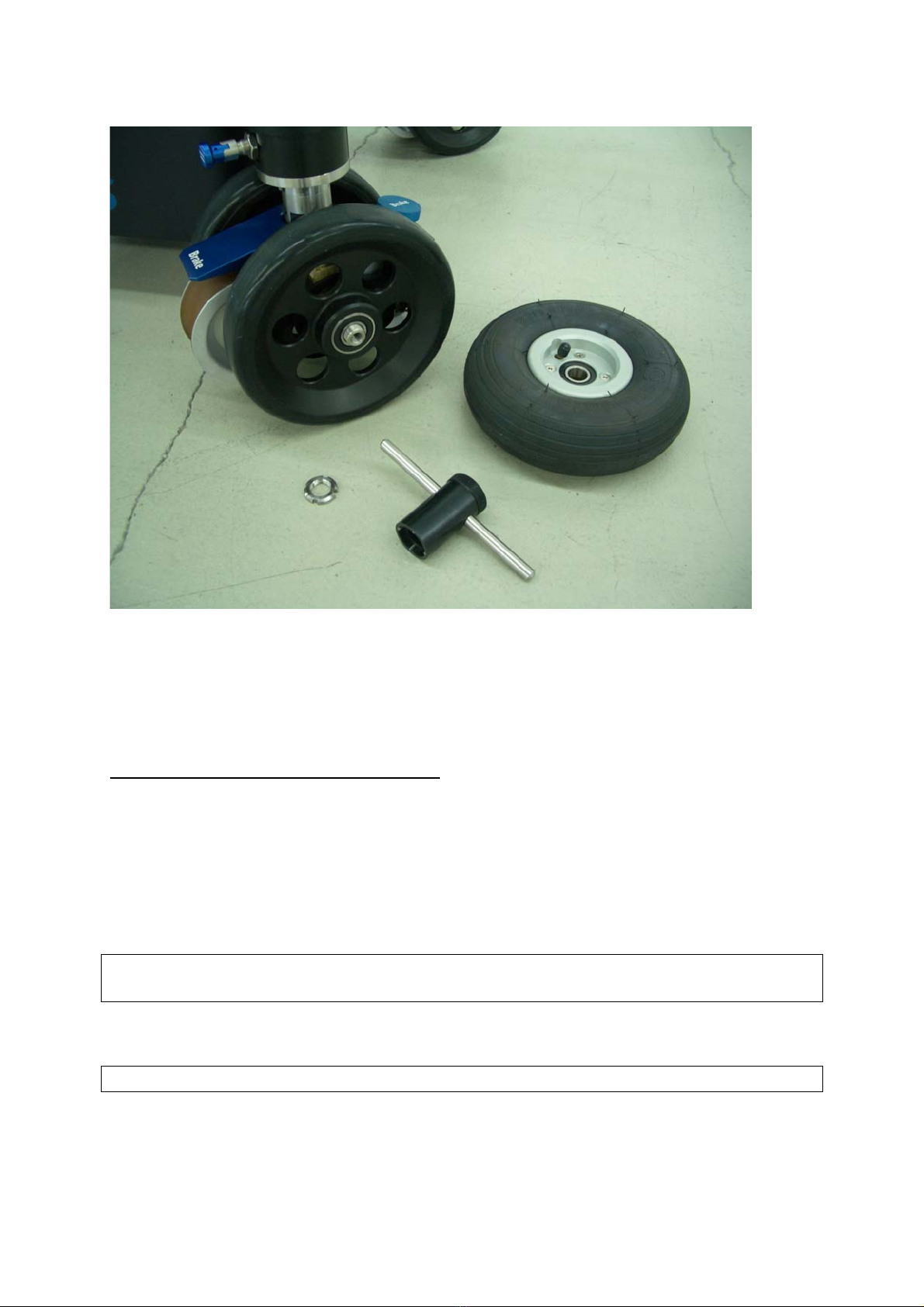

The dolly can be moved with one-wheel steering by taking off a Kombi-Wheel

(dovetail-connection). The blue switch must be set at „Steer“ and the one wheel

that is used to steer must be disengaged, as with driving on track (bolt on Kombi-

Wheel). Please note there is a higher risk of tilting due to the smaller basis (three

legs). Use the one-wheel-steering only in studios or at zero wind speed.

The most important points when operating Crab + Steer:

Before switching over, the kombi wheels must be in the direction of

movement.

While switching, the Shiftbox may be supported by lightly moving the

steering wheel in a left/right direction.

,,Steering“ (2 wheels) is only possible from two wheel arms (operating side).