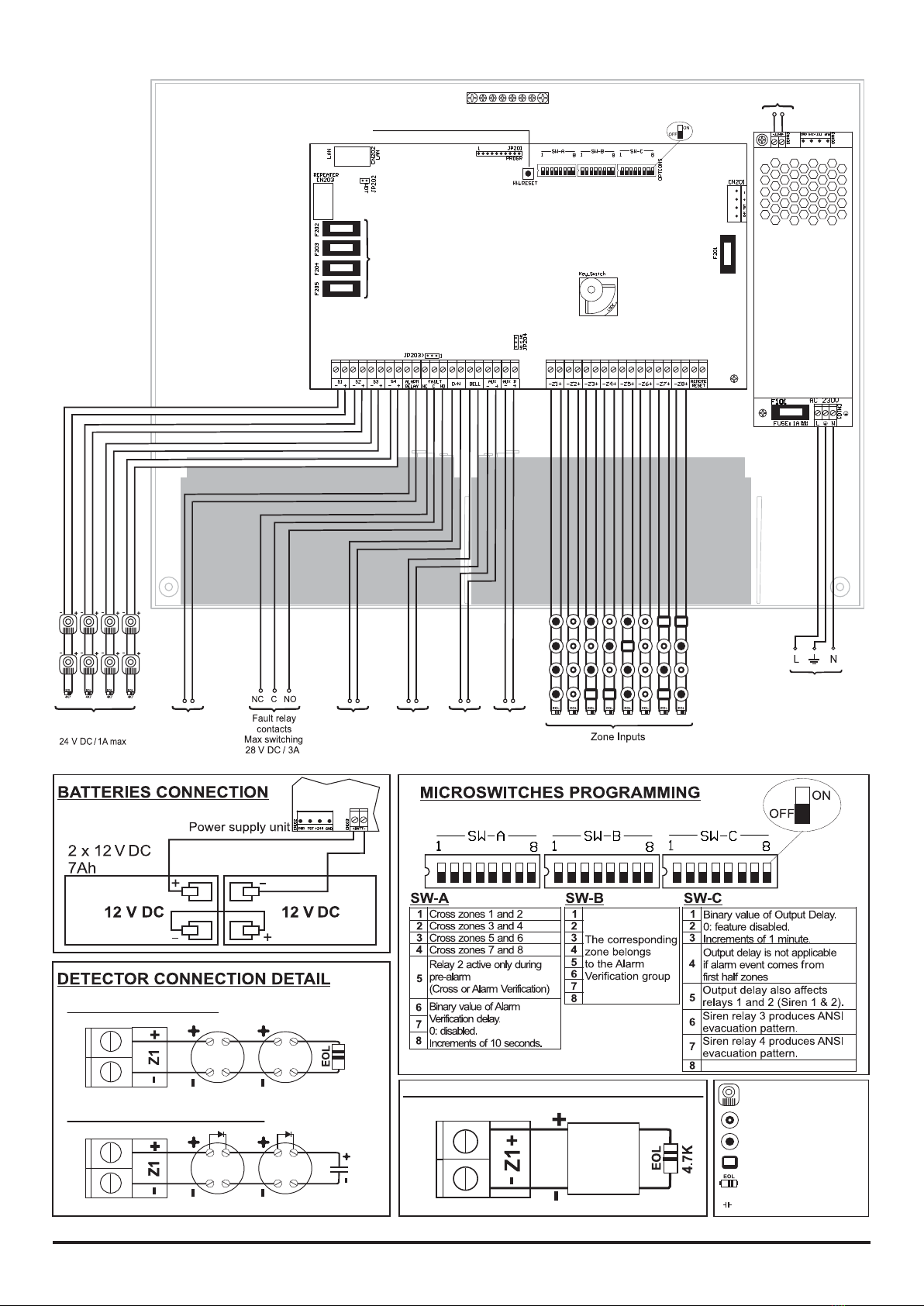

8Neon - Conventional Fire Alarm Control Panel

Any new alarm event will automatically cancel the silence.

If no sounders are active, the silence operation will only

momentarily activate the corresponding indicator.

Bell / Class change (Long Press)

While key [2] is kept pressed, the Sounders normally used

for Fire Alarms, are activated with a constant pattern. This

is typically used in schools to sound a class change.

Siren 2 output will not be used if allocated to the pre-

alarm function.

While the panel is in this mode, all indicators are turned o

and only the activated relay indicators (S1 to S4) are blink-

ing every 0.25 seconds.

The panel returns to normal indication when the key is re-

leased.

Key [3]: Alarm Verication Toggle

Only useful if the installation uses the Alarm Verication

functionality.

The Alarm Verication operation may be disabled and re-

enabled with successive presses of key [3] (see section

5.3.9 for indication).

The user may verify which zones (if any) belong to the

alarm verication group by pressing and holding key

[3]. While this key is kept pressed the *ALARM

VERIFICATION* indicator ashes at a slow rate while

blinking disablement indicators show the group

members (see section 5, Alarm Verication).

Key [4]: Output Delays Toggle

Only useful if the installation uses the “Output Delays”

feature.

The Output Delays operation may be disabled or re-en-

abled with successive presses of key [4] (see section 5.3.8

for indication).

Key [5]: ZONES Disablement

Used to selectively place zones in disabled mode. A dis-

abled zone is fully ignored by the system in both faults and

alarms.

How to operate:

1. Press Key [5]: *DISABLEMENTS* indicator starts

blinking: the panel is in zone selection mode.

2. Use keys [1] to [8] to toggle the disablement of the

corresponding zone.

3. The *Disablements | Test | Faults* indicators show

any zones that are disabled (“steady on” state).

Panels with 2 or 4 zones will ignore the keys with no

corresponding zone.

Zone selection mode will be cancelled after 10 seconds

of user inactivity.

Disabling a zone in alarm will cancel the alarm state but will

not reset any automatic detectors that may have caused/

latched the alarm.

Key [6]: ZONES test

Used to place zones in the “Test” state. It is used for testing

the panel as well as any automatic detectors attached to

the zone of interest.

Any alarm condition detected from a zone in test will cause

the panel’s buzzer and the local Sirens (relays 1 to 4) to be

activated for 3 seconds. After the 3 second activation the

panel performs a zone reset (useful for automatic detec-

tors).

Any zone in this state is considered disabled and is so in-

dicated.

If any zone is in test mode, the *TEST* indicator is

illuminated.

Key [7]: EVACUATION (Long Press)

This operation requires Access level 2 if SW-C-8 is set

(see section 8.3 key [7], above).

Key [8]: RESET panel

Exit A.L.2 (Long Press)

The reset operation will:

• Remove power from the zone circuits for 3 seconds,

resetting all automatic detectors.

• Restore all Outputs to their idle state.

• Cancel any pending pre-alarms.

• Cancel all Alarm Verication timers (if active and run-

ning).

• Cancel all faults including the startup System Fault.

“Remote Reset” Hardware input.

The remote reset input, if used, is connected to a

momentarily activating push-button (shorted while kept

pressed). This will cause the panel to do an Access Level

2 reset operation.

5.3 Indications

5.3.1 POWER Indication

The *POWER* indication is permanently ON if the main

power is present and batteries are healthy. This condition

signies normal system operation.

*POWER* indicator OFF signies a total power failure of

the system. This can be due to a number of reasons. Some

of them are:

• Main power failure for an extended period of time during

which the batteries have been depleted.

• Blown main board fuse (see section 1.1).

• Other malfunction of the power supply, main board

disconnected from PSU (power supply unit) etc.

Blinking power indicator signies one of the following:

(a) Removal or power loss of the batteries.

(b) Main power loss.1

(c) Blown main power fuse or PSU fuse (see section 1.1).

In the above cases the on board buzzer sounds continu-

ously.

1The *POWER SUPPLY FAULT* indicator turns ON.

5.3.2 AUX POWER Fault Indication

When active, this indicator signies that an overcurrent

condition at the auxiliary power outputs (section 1.1, items

18 & 19) is detected. The maximum allowed total current

for the two auxiliary outputs is 1 Amp. The panel is capa-

ble of continuous operation even with a full short circuit at

these outputs. Please note that a short on any one of the

two outputs will disable both as well as any device powered

from them.

If more than 1 Amp is required, a compatible EN 54-4 ap-

proved re alarm power supply must be used. When such

a power supply is used, the negative output of the external

power supply must be connected to the negative terminal

of the AUX terminal (-AUX).

IMPORTANT: The total current of the auxiliary out-

puts plus the siren outputs must not exceed 1.5 Amp.

5.3.3 Battery Fault / Replace Indication

The Neon panel uses a battery fault detection system that

will generate a battery fault indication in the following cases: