DEVICE MAINTENANCE AND CLEANING

TRAINING

©Parata

Connect the power supply plug to the power source firmly after removing the dust on

the plug. A dusty plug or improper insertion may cause abnormal heating or ignition.

Disconnect the power supply plug if there is something wrong with the device.

Continued abnormal operation may cause electric shock or fire.

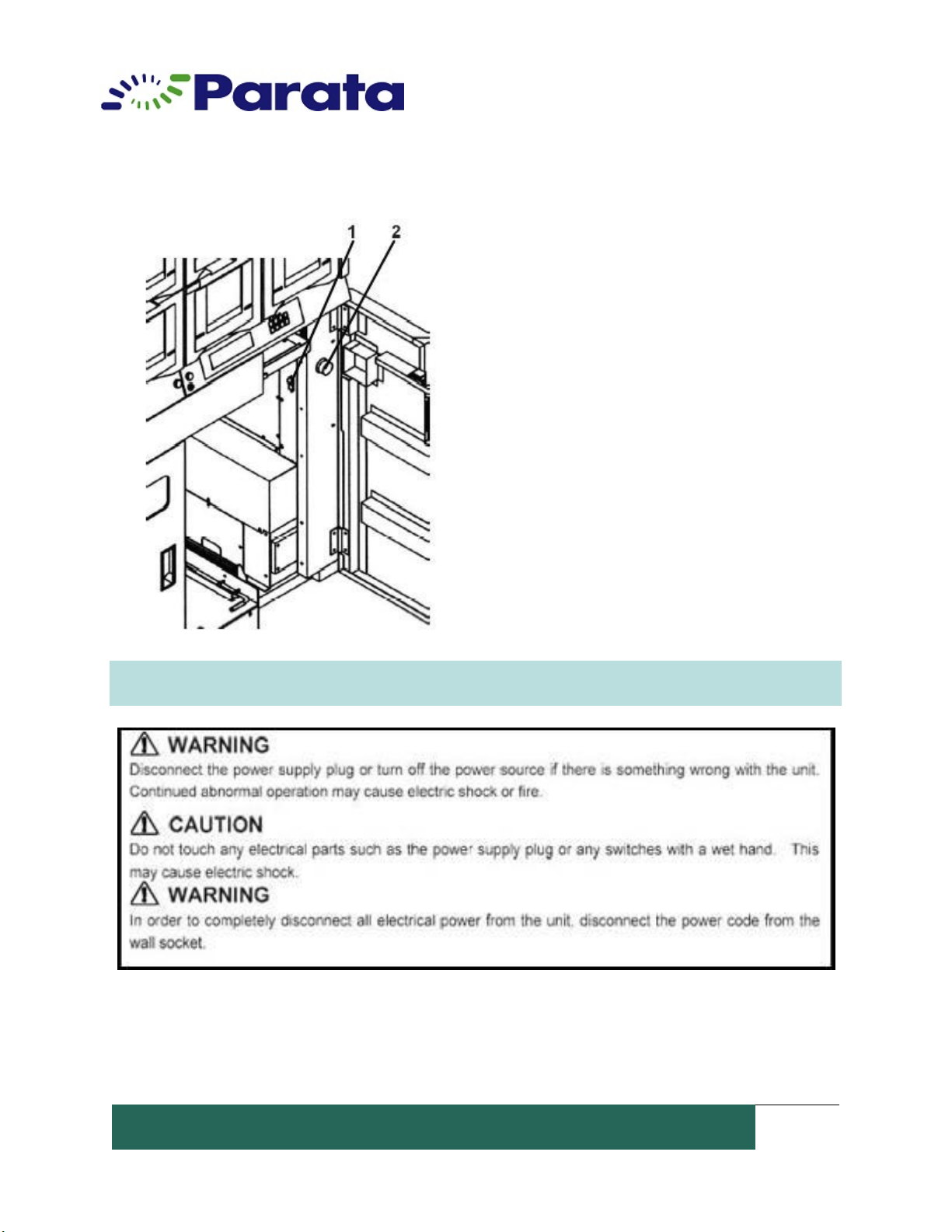

Turn off the power switch and disconnect the power supply to the device prior to any

repair or maintenance to prevent electric shock or injury.

Always ground the device to prevent electric shock. If the power supply outlet is not

grounded, a qualified engineer must install a ground.

Never disassemble, repair, or modify the unit yourself. Any work carried out by an

unauthorized person may result in fire, electric shock or injury due to a malfunction.

Never splash water directly onto the device as this may cause electric shock or a short

circuit.

Never ground the device through a gas pipe, water main, telephone line or lightening

rod. This may cause electric shock.

Do not insert metal objects such as pins or wires into any vent, gap or outlet on the

unit. This may cause electric shock or injury by accidental contact with moving parts.

Never insert a finger or any object into the exhaust vent. This may cause injury since

the fan is turning with high speed inside the device.

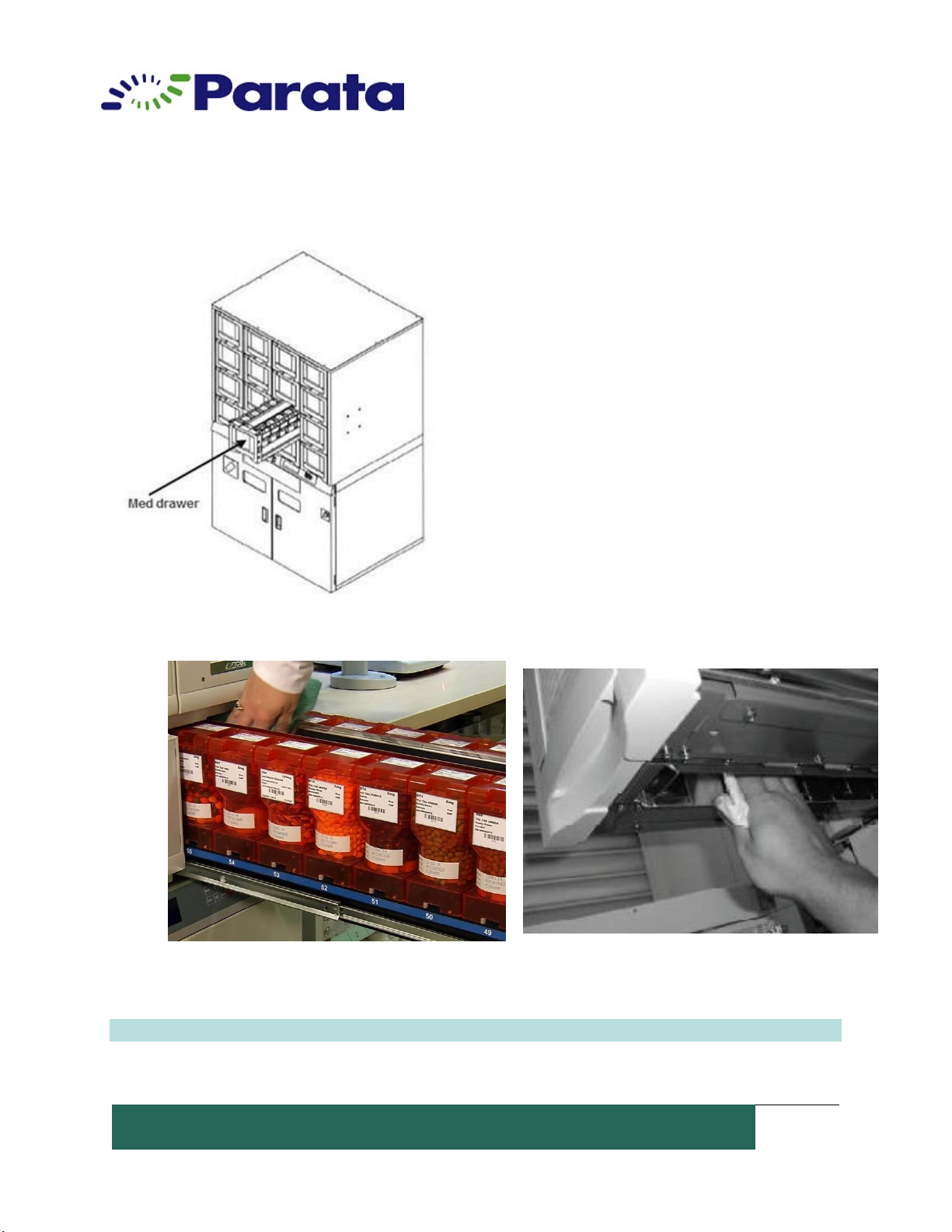

Never insert a hand or any object into the package exit. This may cause injury by

accidental contact with moving parts.

Never touch the heater block. High temperature may cause injury.

Never touch the heater block until the heater block is cooled down. It will remain hot

even if the power switch is tuned off, and may cause injury.

Turn off the power switch prior to cleaning. Do not touch the cutter blade or

perforation knife as they may cause injury.

Always use the canister for the dedicated medication. The canister is assigned to one

medication.

Medication in the device may be affected by temperature and humidity. The device is

not a cabinet for medication storage.

Precautions for Safe Operation

When removing the plug from the power supply outlet, grasp the plug, not the cord.

Pulling the cord may result in electric shock or fire by short circuit.

Do not touch any electrical parts such as the power supply plug or any switches with a

wet hand. This may cause electric shock.