TABLE

OF

CONTENTS

Chapter/Paragraph Title Page

1.

GENERAL INFORMATION AND SAFETY

PRECAUTIONS

1-1 Safety

Precautions………………………………………………………………………………………………1

-1

1-2

Introductio

n……………………………………………………………………………………………………...

1-1

1-3

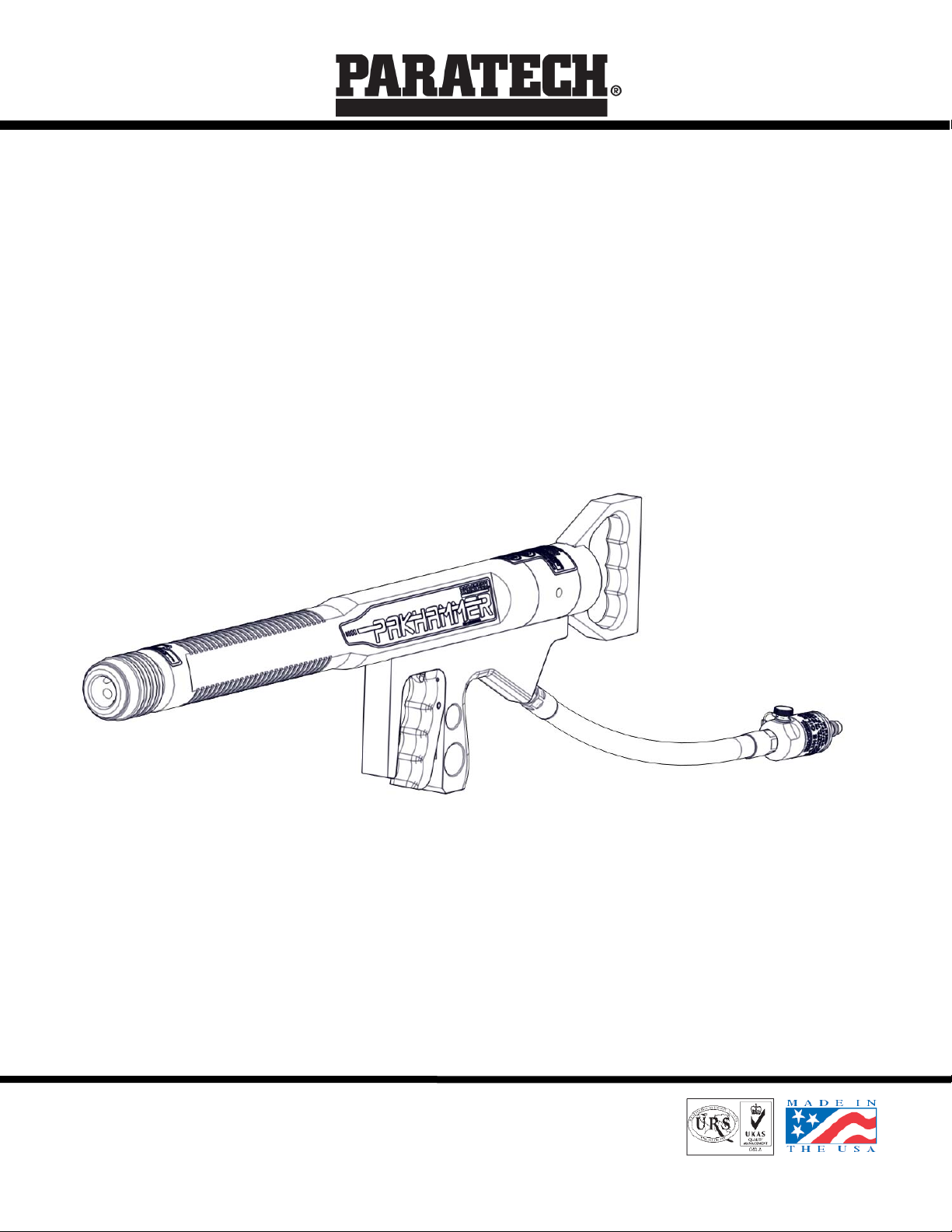

Equipment

Description

…………………………………………………………………………………………………..

1-1

1-4

Relationship

of

Units……………………………………………………………………………………………………….

1-1

1-5

Reference

Data

………………………………………………………………………………………………....

1-1

1-6

Equipment, Accessories and Documents

Supplied

…………………………………………………………..

1-1

2. OPERATION

2-1

Introduction............................................................................................................................................

2-1

2-2

Preparation

for

Use...............................................................................................................................

2-1

2-3

Controls

and

Indicator

s

.

.........................................................................................................................

2-1

2-4

Application

s

...........................................................................................................................................

2-1

2-5

NormalOperating Procedure.................................................................................................................

2-1

2-6

Shutdown...............................................................................................................................................

2-4

3.

THEORY

OFOPERATION

3-1

General.................................................................................................................................................

3-1

3-2

General

Constructio

n

............................................................................................................................

3-1

3-3

Theory

of

Operation .............................................................................................................................

3-1

4.

SCHEDULE

D

MAINTENANCE

4-1

Introductio

n...........................................................................................................................................4

-1

4-2

MaintenancePla

n

……………………....................................................................................................

4-1

4-3

General

Maintenance

…...

.......................................................................................................................

4-1

5. TROUBLESHOOTING

5-1

Introductio

n……………………………………………………………………………………………………..

5-1

6.

CORRECTIVE

MAINTENANCE

6-1

Introductio

n.................................................................................................................................

6-1

6·2

Adjustments........................................................................................................................................................

6-1

6-3

Alignment………………………………………………………………………………………………………….

6-1

6-4

Pakhammer Repair……………………………………………………………………………………………….

6-1

6-5

Oiler and Hose Assembly Repair……………………………………………………………………………….

6-6

7. PARTS LIST

7-1

Introductio

n……………………………………………………………………………………………………...7-1

7-2 List of Major Components

……………………………………………………………………………………7-1

7-3

Parts List Tables

………………………………………………………………………………………………..7-1

7-4

List of Manufacturers

…………………………………………………………………………………………...7-1

i