4Parker Hannifin Corporation Bulletin TI-HFX-3D

Location

Utilities

Installation with a

Receiving Tank

Moving

General

The Balston Nitrogen Generator is shipped on a wooden skid. The generator may be removed from

the skid when it arrives at the customer location, or it may be transported to its final destination while

skidded. If the generator is removed from the skid, use a two-wheeled dolly. If the generator

remains skidded while being moved, use a device approved for transporting skidded products.

The Balston Nitrogen Generator is a free-standing unit. Do not suspend the Nitrogen GeneratorDo not suspend the Nitrogen Generator

Do not suspend the Nitrogen GeneratorDo not suspend the Nitrogen Generator

Do not suspend the Nitrogen Generator

from the wall or ceiling. Its considerable weight and size could pose a falling hazard.from the wall or ceiling. Its considerable weight and size could pose a falling hazard.

from the wall or ceiling. Its considerable weight and size could pose a falling hazard.from the wall or ceiling. Its considerable weight and size could pose a falling hazard.

from the wall or ceiling. Its considerable weight and size could pose a falling hazard.

The inlet and outlet on the HFX-3 and HFX0-3 are 1/4" female NPT. A 1/4" male connector which will

withstand 145 psig (10 barg) should be used to connect to the nitrogen generator.

Shutoff Valve -Shutoff Valve -

Shutoff Valve -Shutoff Valve -

Shutoff Valve - A shutoff valve should be installed directly upstream from the nitrogen generator to

facilitate routine maintenance and troubleshooting procedures. The valve should always beThe valve should always be

The valve should always beThe valve should always be

The valve should always be

opened slowly.opened slowly.

opened slowly.opened slowly.

opened slowly. Opening a valve quickly will pressurize the membrane too rapidly and may cause

membrane rupture. Membrane failures resulting from improper valve installation will not be covered

under warranty.

Pressure Regulator -Pressure Regulator -

Pressure Regulator -Pressure Regulator -

Pressure Regulator - A pressure regulator should be installed directly upstream from the nitrogen

generator to set and maintain the inlet air pressure. Maintaining a constant inlet air pressure is

critical to the performance of the system.

Flow Controller -Flow Controller -

Flow Controller -Flow Controller -

Flow Controller - If the application requires nitrogen at pressures higher than 10 psig (0.7 barg),

install a flow controller downstream from the nitrogen generator, close to the point of use (see

Adjustment Procedure section, page 9).

The generator should be located indoors, protected from severe weather conditions, and free from

excessive ambient dust or dirt. Do not install the generator outdoors.Do not install the generator outdoors.

Do not install the generator outdoors.Do not install the generator outdoors.

Do not install the generator outdoors. The ambient temperature

of the air surrounding the generator must be between 60°F and 95°F (15°C and 35°C). Allow a

minimum of 6" (15 cm) clearance on all sides of the generator.

The environment surrounding the nitrogen generator should also be adequately ventilated.The environment surrounding the nitrogen generator should also be adequately ventilated.

The environment surrounding the nitrogen generator should also be adequately ventilated.The environment surrounding the nitrogen generator should also be adequately ventilated.

The environment surrounding the nitrogen generator should also be adequately ventilated.

The generator creates a 30% to 40% oxygen permeate stream which may pose a flammabilityThe generator creates a 30% to 40% oxygen permeate stream which may pose a flammability

The generator creates a 30% to 40% oxygen permeate stream which may pose a flammabilityThe generator creates a 30% to 40% oxygen permeate stream which may pose a flammability

The generator creates a 30% to 40% oxygen permeate stream which may pose a flammability

problem in an oxygen sensitive environment.problem in an oxygen sensitive environment.

problem in an oxygen sensitive environment.problem in an oxygen sensitive environment.

problem in an oxygen sensitive environment.

Compressed Air -Compressed Air -

Compressed Air -Compressed Air -

Compressed Air - The Balston HFX-3 and HFX0-3 Nitrogen Generators require a source of clean,

dry compressed air for operation. The incoming air should be between 60°F and 95°F(15°C and

35°C), have a dewpoint less than the ambient temperature, and be relatively free of water, compres-

sor oil, hydrocarbons, and particulate matter. The inlet pressure of the compressed air supply

should be regulated to 60 psig to 145 psig (4.1 barg to 10 barg).

Power - If the Balston 72-730 oxygen analyzer is being used as an accessory,Power - If the Balston 72-730 oxygen analyzer is being used as an accessory,

Power - If the Balston 72-730 oxygen analyzer is being used as an accessory,Power - If the Balston 72-730 oxygen analyzer is being used as an accessory,

Power - If the Balston 72-730 oxygen analyzer is being used as an accessory, a 120 VAC or

240 VAC, 50/60 Hz power supply is required to energize the oxygen analyzer. (Note:Note:

Note:Note:

Note: Main supply

line voltage must be within 10% of the nominal rated voltage for the generator.) The power recep-

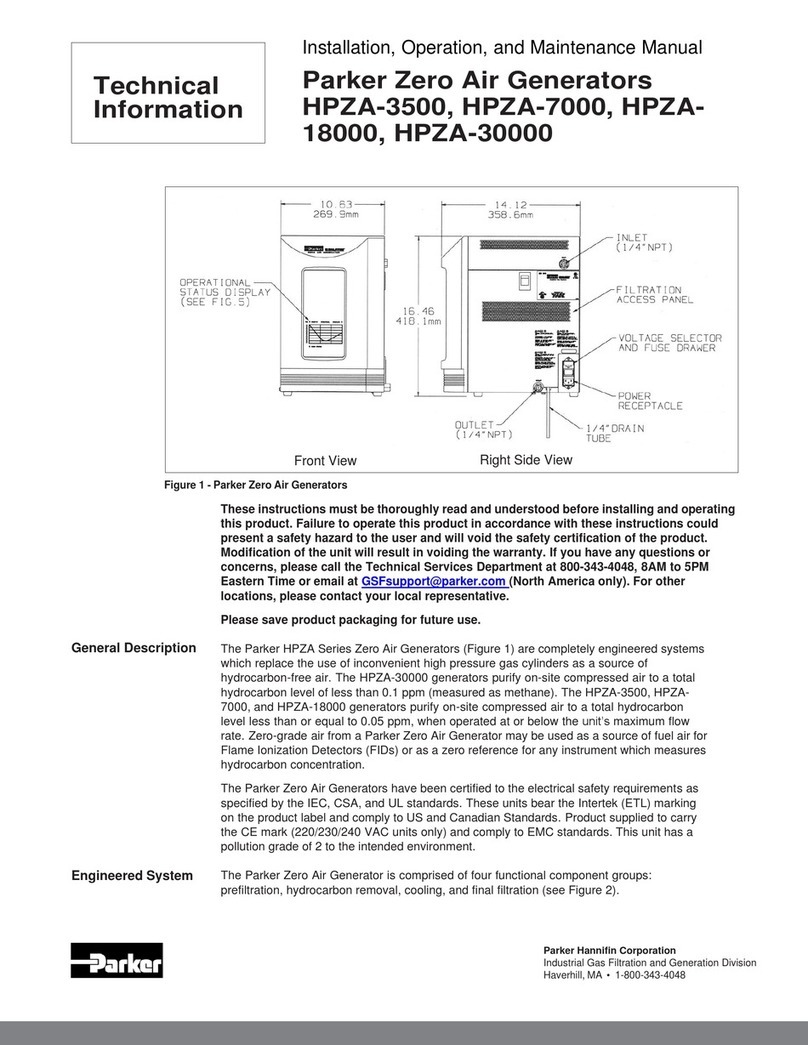

tacle is located on the back of the unit (see Figure 1).

Drain Lines -Drain Lines -

Drain Lines -Drain Lines -

Drain Lines - The 1/4" plastic drain lines from the first two stages of prefiltration (see Figure 1)

should be piped away to an appropriate disposal container. The liquid in this drainage will consist

primarily of water and compressor oil and should be disposed of properly.

In many applications, the process flow requirements for nitrogen fluctuate with time. As noted

earlier, if the flowrate of the emergent nitrogen stream varies, the purity level of the nitrogen stream

also varies; therefore, it is important to keep the nitrogen flow as constant as possible. A receiving

tank can be installed between the nitrogen generator and the process to accommodate fluctuations

in nitrogen demand and maintain nitrogen purity.

If a receiving tank is to be used, a back pressure regulator and a check valve should be installed

between the Balston Nitrogen Generator and the receiver tank (see Figure 5). The 72-460 Back

Pressure Controller contains both of these components and may be ordered as an accessory for the

Nitrogen Generator. The adjustable back pressure regulator, when set to the appropriate pressure,

will maintain a constant pressure drop across the flow control valve. By controlling the pressure

drop across the flow control valve, the nitrogen flow will be kept constant and the variability in purity

of the nitrogen process stream will be minimized. The check valve, when installed properly, will

prevent any flow of nitrogen from the receiver upstream toward the generator, providing a more

effective means of storing the emergent nitrogen.

Installation