2

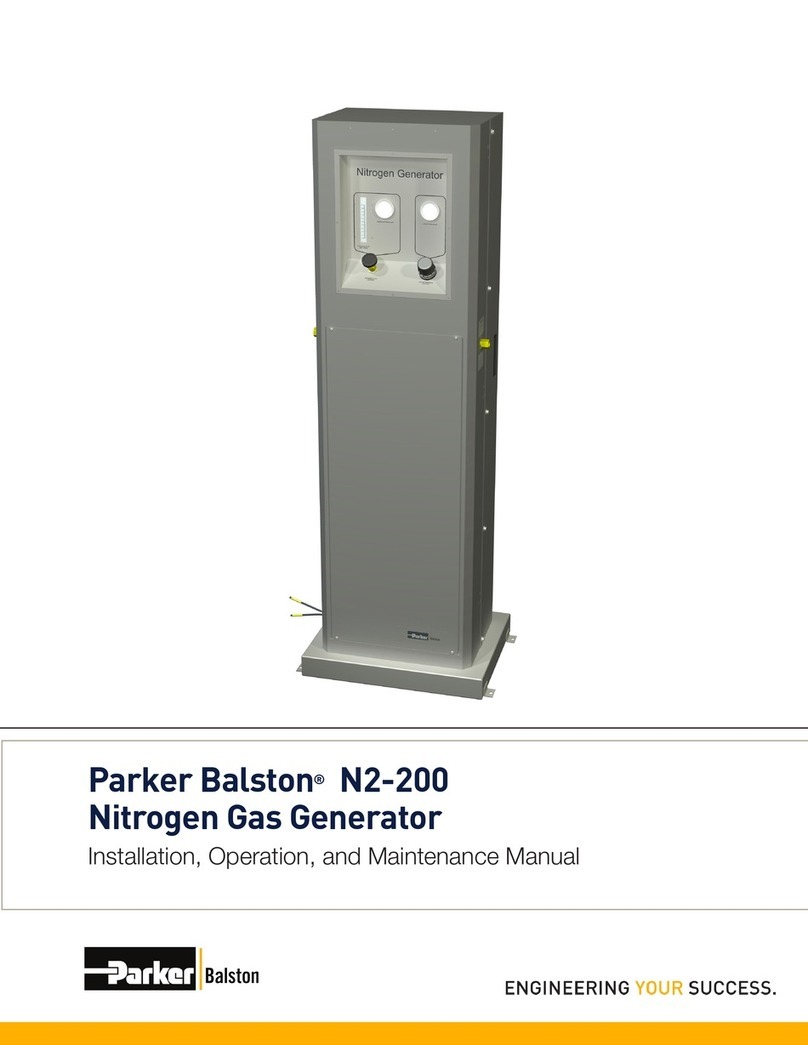

NITROGEN GENERATORSINSTALLATION, OPERATION, AND MAINTENANCE MANUAL

TABLE OF CONTENTS

Page

1. WARRANTY.............................................................................................................3

2. SAFETY PRECAUTIONS...........................................................................................4

3. GENERAL DESCRIPTION.........................................................................................5

4. ENGINEERED SYSTEM............................................................................................5

4.1 Prefiltration .......................................................................................................6

4.2. Air Separation ..................................................................................................6

4.3 Final Filtration ....................................................................................................6

4.4 Controls ............................................................................................................6

5. OXYGEN MONITORING ...........................................................................................7

6. INSTALLATION .......................................................................................................7

6.1 Moving..............................................................................................................7

6.2 General.............................................................................................................8

6.3 Location............................................................................................................9

6.4 Utilities..............................................................................................................9

6.5 Installation with a Receiver Tank........................................................................ 10

7. OPERATION ......................................................................................................... 11

7.1 Startup............................................................................................................ 11

7.2 System Adjustment for Desired Outlet Purity...................................................... 11

8. NITROGEN FLOW AT GIVEN OPERATING PRESSURE AND PURITY .......................... 12

9. OPERATION ADJUSTMENT PROCEDURES.......................................................... 14

9.1 Atmospheric Pressure Applications (<10 psig / 0.7 barg).................................... 14

9.2 Elevated Pressure Applications (>10 psig) ......................................................... 15

9.3 Receiving Tank Applications ............................................................................. 16

9.4 Temperature Equilibrium .................................................................................. 16

9.5 Evaluation ....................................................................................................... 17

9.6 System Upsets ................................................................................................ 17

9.7 Shutting Down ................................................................................................. 17

10. MAINTENANCE................................................................................................... 17

10.1 Cleaning........................................................................................................ 18

10.2 Filter Cartridge Replacement .......................................................................... 18

10.3 Activated Carbon Filter Replacement............................................................... 19

10.4 Ordering Information...................................................................................... 19

11. NITROGEN GENERATION SYSTEM SPECIFICATIONS ........................................... 20

11.1 Approximate Inlet Air Consumption at 68°F by Purity and Pressure..................... 20

11.2 Optional Accessories...................................................................................... 21

11.3 Cautions........................................................................................................ 21

12. TROUBLESHOOTING .......................................................................................... 22