DOC-0017-10-EN: AC20 Series PROFINET IO Option

DOC-0017-10-EN-B 04.04.2023 7 (47)

4 Table of Contents

1Safety.................................................................................................................................................... 2

1.1 Intended Users............................................................................................................................ 2

1.2 Application Area .......................................................................................................................... 2

1.3 Personnel .................................................................................................................................... 2

1.4 Product Warnings........................................................................................................................ 2

1.5 Safety Information ....................................................................................................................... 3

2Manufacturing Location...................................................................................................................... 5

3Waste Electrical and Electronic Equipment (WEEE) ....................................................................... 6

4Table of Contents ................................................................................................................................ 7

5Introduction.......................................................................................................................................... 8

5.1 Product Features......................................................................................................................... 8

6Installation............................................................................................................................................ 9

6.1 Order Codes................................................................................................................................ 9

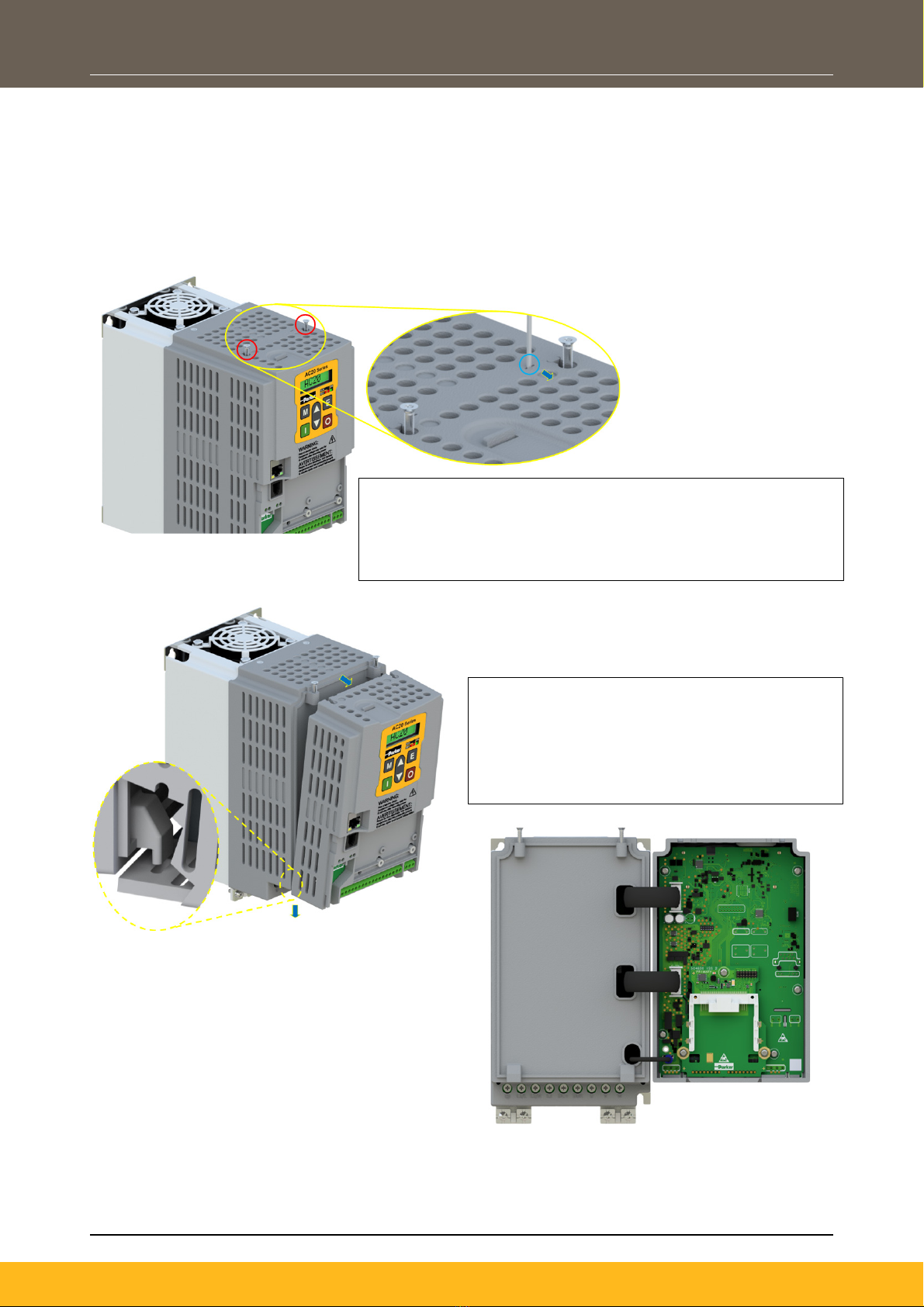

6.2 Fitting the Option....................................................................................................................... 10

7Network .............................................................................................................................................. 13

7.1 Network Connector and Cable Specification ............................................................................ 13

7.2 LED Indications ......................................................................................................................... 13

8Configuration..................................................................................................................................... 15

8.1 Communication parameters...................................................................................................... 15

8.2 Process Data............................................................................................................................. 18

8.3 Acyclic Data Exchange ............................................................................................................. 20

8.4 PROFINET GSDML File ........................................................................................................... 20

9Example Configuration and Programming ..................................................................................... 21

9.1 AC20 Motor Control Application................................................................................................ 21

9.2 List of process data................................................................................................................... 22

9.3 Programming with Siemens PLC .............................................................................................. 22

10 Option Module Webserver................................................................................................................ 34

11 FTP Server.......................................................................................................................................... 37

12 Lost Communication Trip................................................................................................................. 38

13 Diagnostic Event ............................................................................................................................... 39

APPENDIX A: Data types ............................................................................................................................ 40

APPENDIX B: Parameters........................................................................................................................... 41

APPENDIX C: Setting IP-Address via Anybus IPCONFIG ....................................................................... 44

APPENDIX D: DSE Lite Quick Start Guide ................................................................................................ 45