5 Parker Hannifin

Pump and Motor Division

Trollhättan, Sweden

Service Manual

Series F01

Bulletin HY30-5502-M1/UK

Operation Check

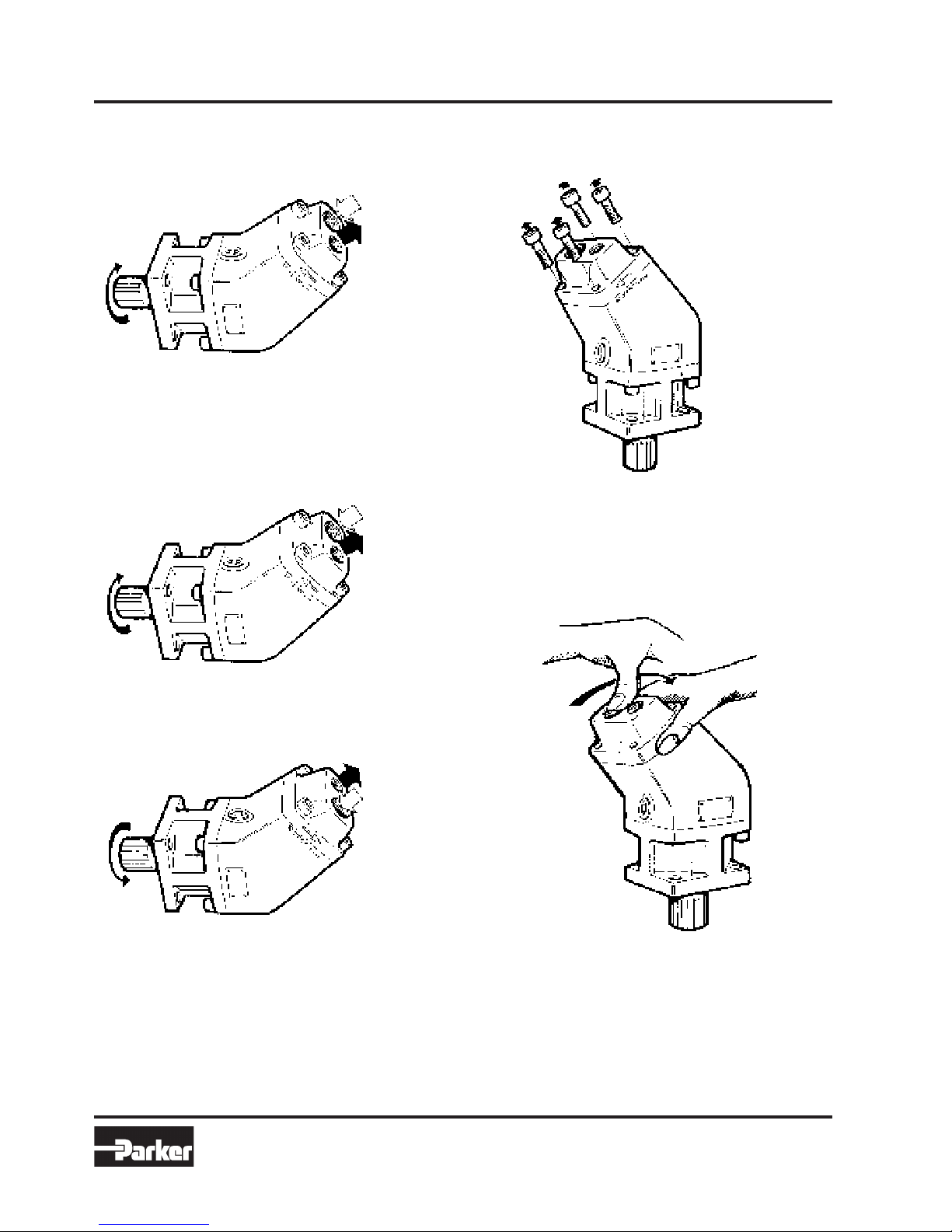

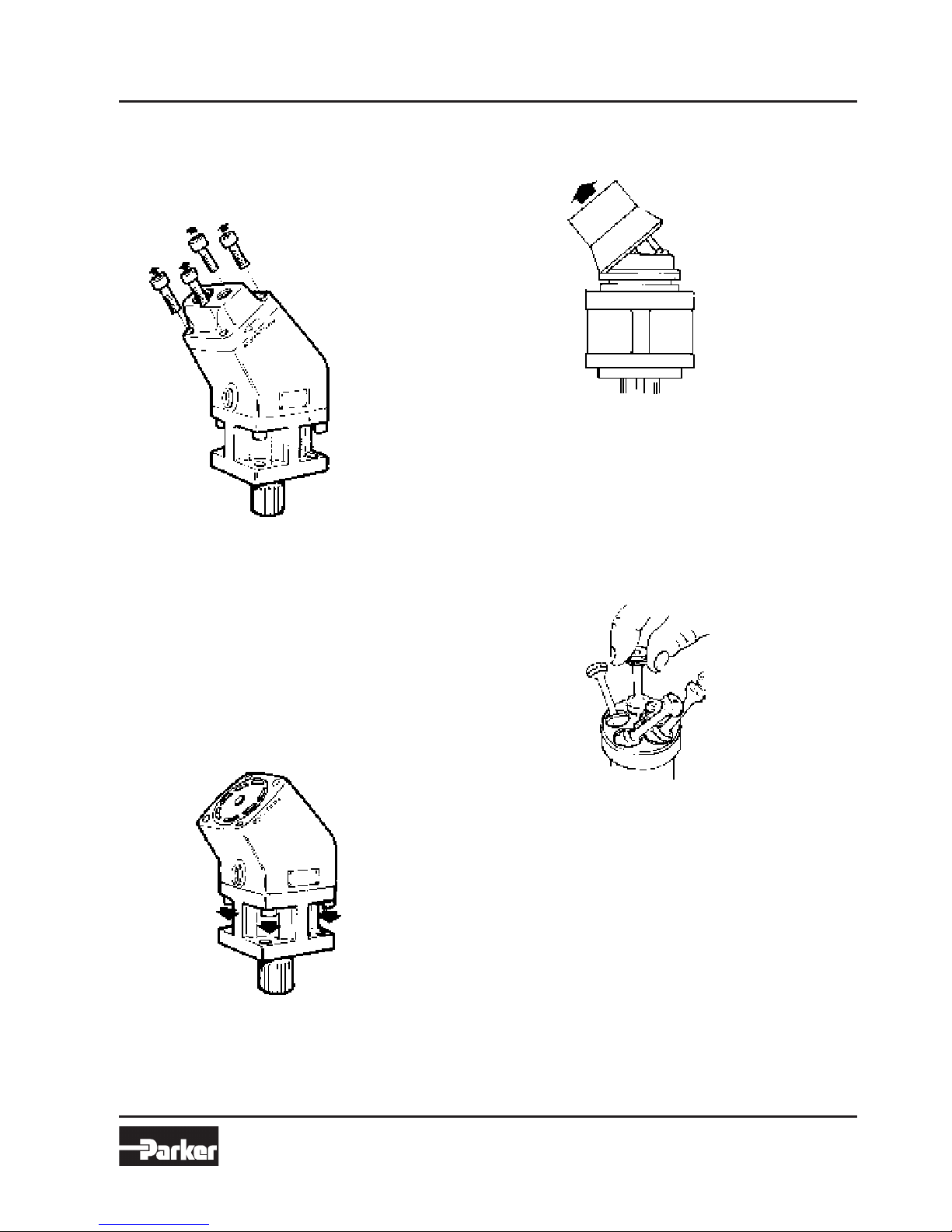

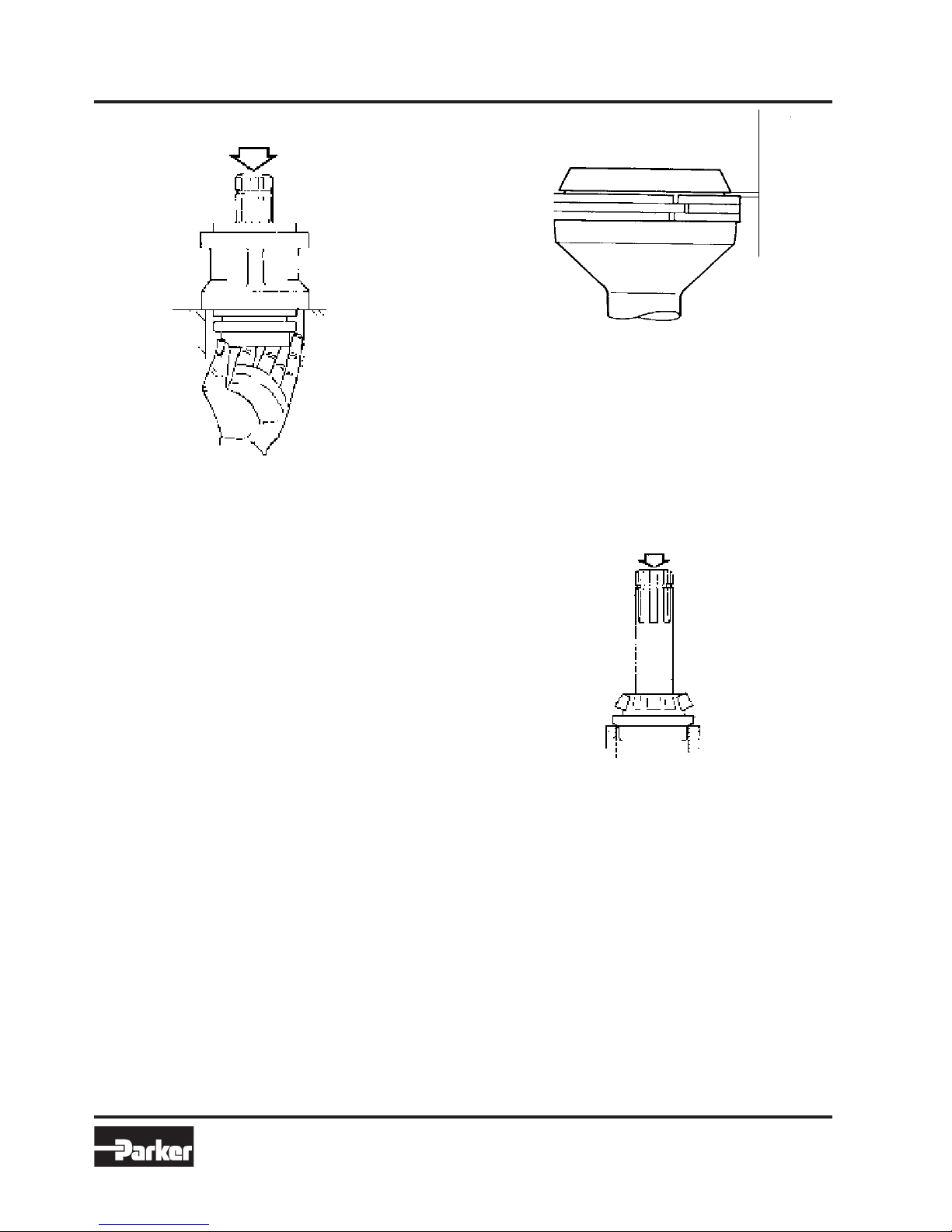

Check of Shaft Seal

The pump has two shaft seals - the inner one sealing the

hydraulic oil in the housing, and the outer one the trans-

misson oil when the pump is fitted to a PTO. If any of the

sealrings leak, the oil will come out through an indication

hole.

Indication hole

Note: A heavy leakage can be caused by a worn-out

pump, whereby high pressure oil will come out into the

housing in such large quantities that the sealring might

be damaged. If there is a steady stream of oil from the

indication hole, the pump is probably damaged and will

have to be replaced.

Check that no oil is dripping out of the indication hole,

when the pump is in operation. If there is a leakage from

the sealrings, they must be exchanged, See chapter ”Ex-

change of shaft seals”.

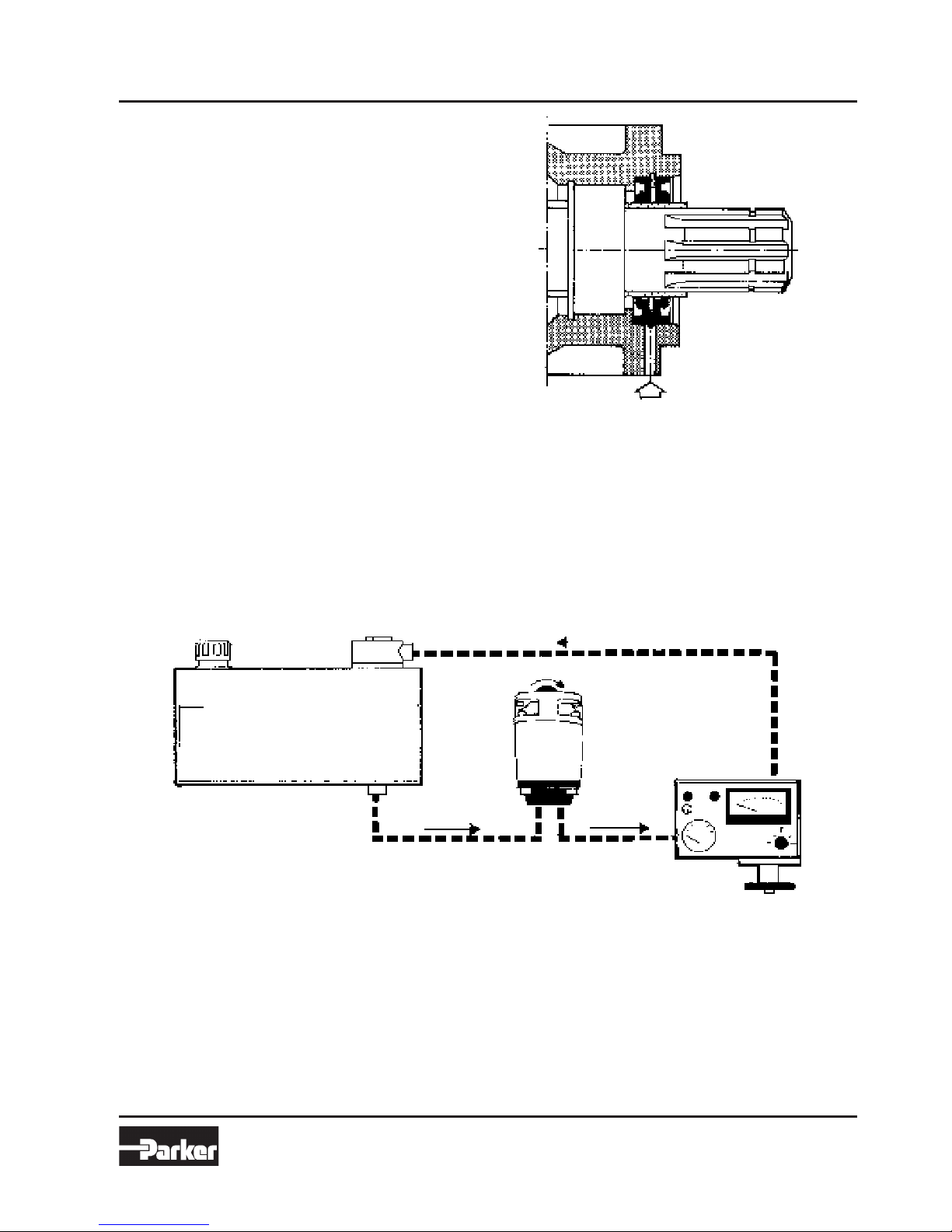

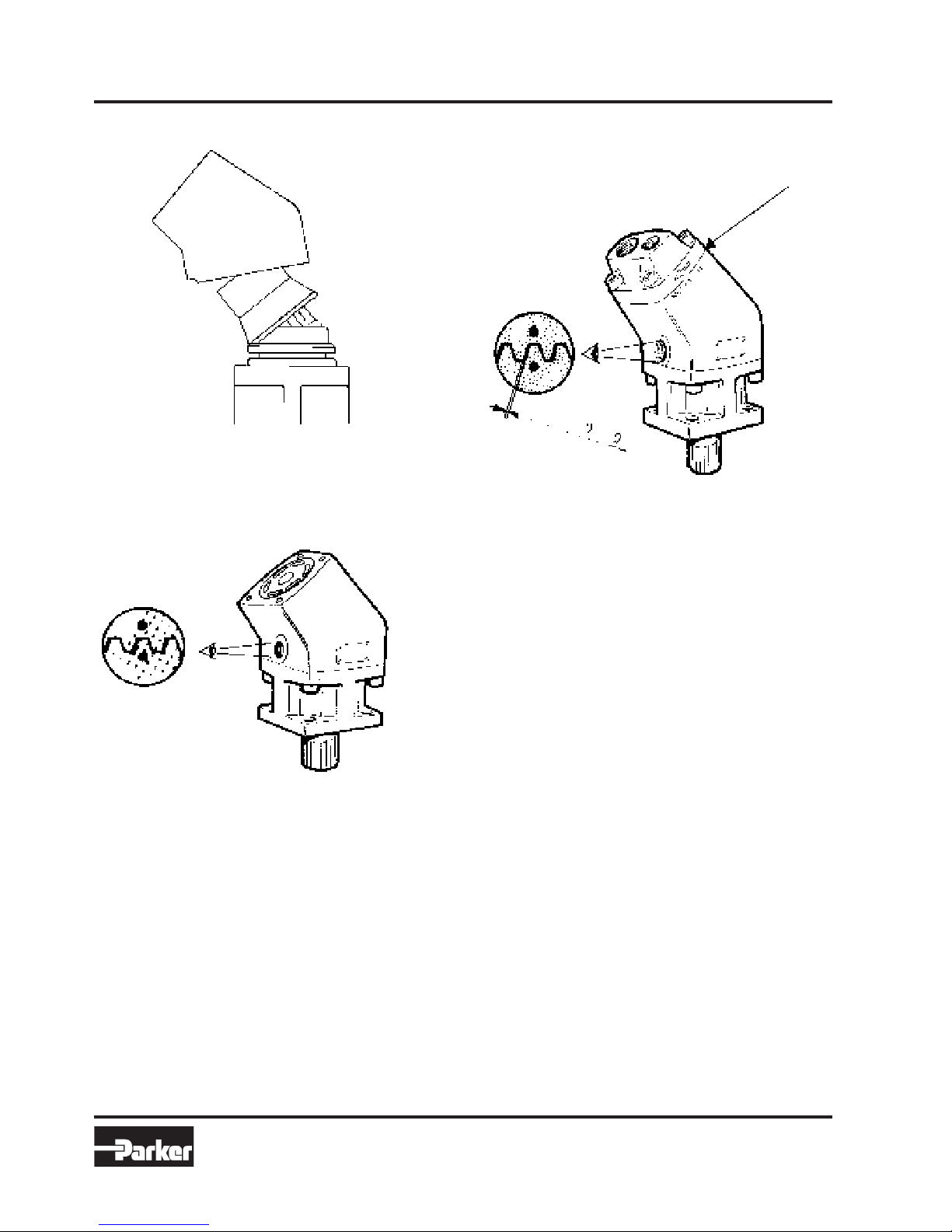

Checking the Flow from the Pump

The flow from the pump can be checked by means of a

test instrument comprising a flowmeter and a relief valve.

Connecton of test instrument

When the pump is running at about 800 - 1400 r.p.m. and

is loaded up to 150 - 200 bar, the flow must not decrease

by more than 10%.

Example:

An F1-40 running at 1225 r.p.m. gives - according to the

flowmeter. - a flow of 48 l/min.

If the pump is loaded, the flow must not decrease by

more than 0,1 x 48 = 4,8 l / min, i.e. the flowmeter should

indicated at least 48 - 4,8 = 43,2 l / min. If the flow drops

below this limit, the pump is worn out and will have to be