Spark Plug Ignition .................................................................................................................................................... 29

Spark Plug Cap .......................................................................................................................................................... 29

Flywheel Maintenance ............................................................................................................................................... 29

Check the Ignition Coil .............................................................................................................................................. 29

Check the trigger coil ................................................................................................................................................. 29

Check the Engine Start Switch .................................................................................................................................. 30

Check the Engine Start Switch .................................................................................................................................. 30

Check the Starting Relay ........................................................................................................................................... 30

Check the Magneto Coil ............................................................................................................................................ 30

Check the Rectifier Regulator.................................................................................................................................... 30

How to Use the Diagnostic Scan Tool ....................................................................................................................... 31

Fault Code Table ................................................................................................................................................ 31

Fuel System ............................................................................................................................................................... 33

Attention: ................................................................................................................................................................... 33

Decomposition Schematic Diagram .......................................................................................................................... 34

Relieve the Fuel Pressure in the Fuel Lines ............................................................................................................... 39

Remove and Check the Fuel Joint ............................................................................................................................. 39

Remove and Check the Fuel Pump ............................................................................................................................ 40

Check the Fuel Filter ................................................................................................................................................. 41

Remove and Check the Electric Fuel Pump .............................................................................................................. 41

Disassembly of electric fuel pump ............................................................................................................................. 41

Check the Fuel Pipe and Fuel Filter ........................................................................................................................... 42

Check the Fuel Common Rail .................................................................................................................................... 42

Check the fuel common rail for leaks or cracks and damage, and replace it if necessary. ........................................ 42

Engine ........................................................................................................................................................................ 42

Attention: ................................................................................................................................................................... 42

Decomposition Schematic Diagram .......................................................................................................................... 43

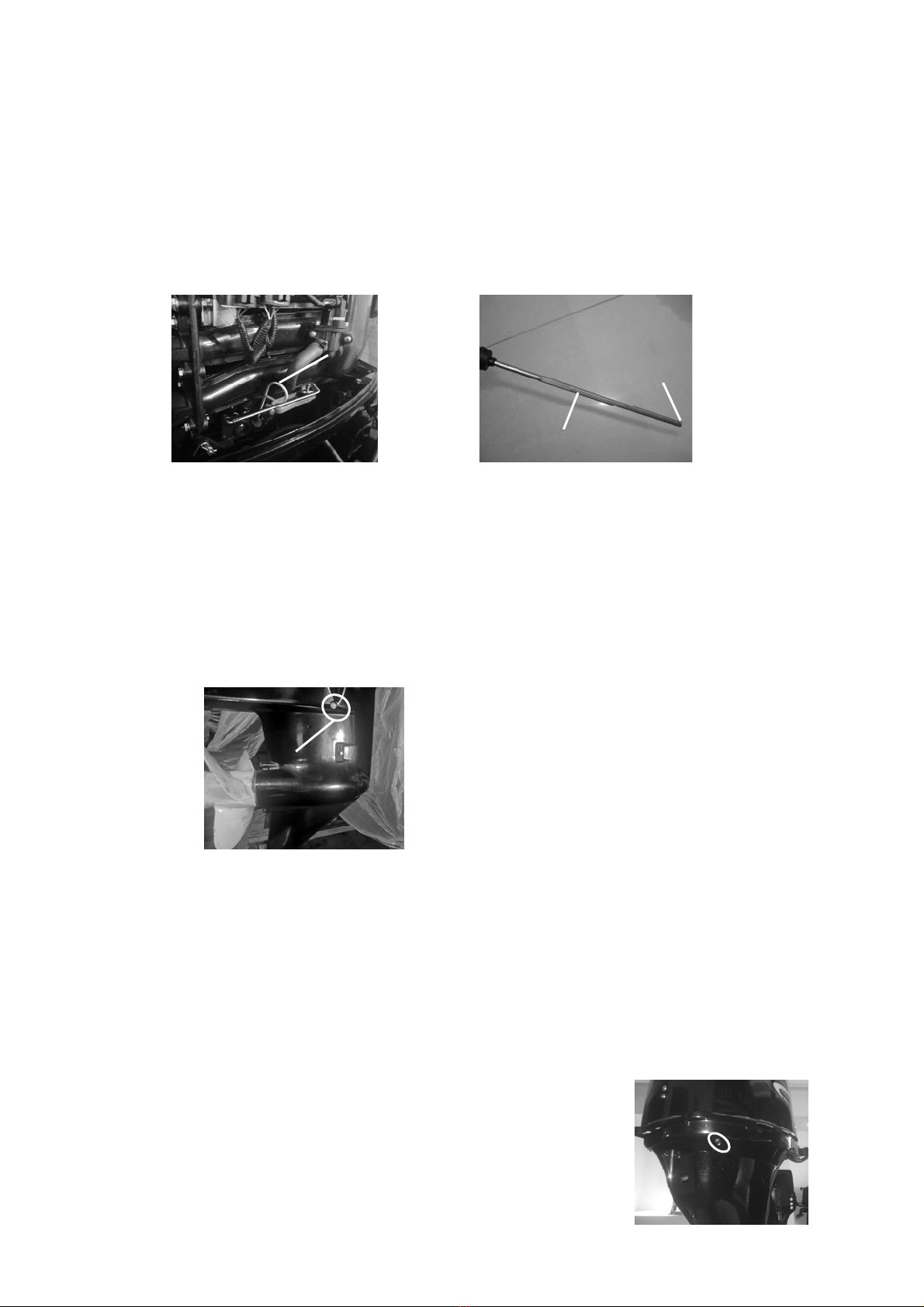

Special Tools .............................................................................................................................................................. 55

Check the Compression Pressure ............................................................................................................................... 55

Check the Oil Pressure ............................................................................................................................................... 55

Disassemble the Engine ............................................................................................................................................. 56

Pulley and Timing Belt .............................................................................................................................................. 56

Disassembling and Check .......................................................................................................................................... 57

Cylinder Head .................................................................................................................................................... 57

Crankcase ........................................................................................................................................................... 61

Reinstall ..................................................................................................................................................................... 65

Assemble Piston Connecting Rod ...................................................................................................................... 65

Install the piston, connecting rod, piston pin and piston pin clip clutch. ........................................................... 65

Install Piston Ring .............................................................................................................................................. 65

Install Piston ...................................................................................................................................................... 65

Install Crankshaft ............................................................................................................................................... 65

Assemble the Engine ......................................................................................................................................... 65

Upper Casing ............................................................................................................................................................. 67

Top Cowling .............................................................................................................................................................. 67

Decomposition Schematic Diagram .................................................................................................................. 67

Disassembling and Check .................................................................................................................................. 68

Bottom Cowling ........................................................................................................................................................ 69

Decomposition Schematic Diagram .................................................................................................................. 69

Disassembling and Check .................................................................................................................................. 73

Steering Handle ......................................................................................................................................................... 74