ASLD2200 - In truction Manual

Table of Contents

1 Introduction.................................................................................................................................................................. 5

1.1 General............................................................................................................................................................. 5

1.2 Output Signal.................................................................................................................................................... 5

1.3 Limit Relay........................................................................................................................................................ 5

1.4 Manual Convention ......................................................................................................................................... 5

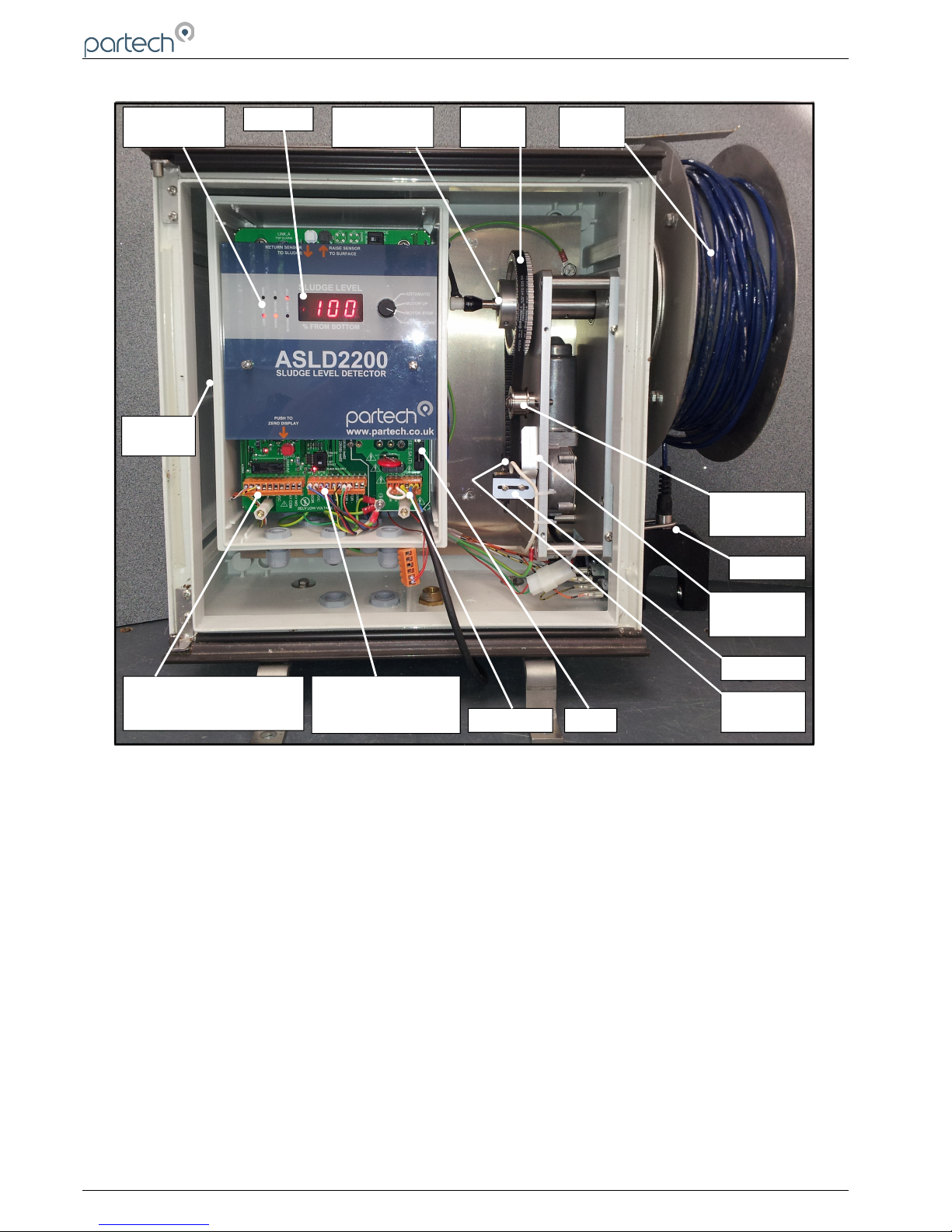

1.5 Mechanical Overview........................................................................................................................................ 6

2 Principle of Operation................................................................................................................................................... 7

3 ASLD2200 Selection.................................................................................................................................................... 8

3.1 Sen or Selection............................................................................................................................................... 8

3.2 Encoder Di c Selection..................................................................................................................................... 9

3.2.1 Encoder Di c Range ................................................................................................................................. 9

4 Control Setting ......................................................................................................................................................... 10

4.1 Up and Down Button ..................................................................................................................................... 11

5 In tallation.................................................................................................................................................................. 12

5.1 Location.......................................................................................................................................................... 12

5.2 Electrical Connection .................................................................................................................................... 13

6 Configuration.............................................................................................................................................................. 14

6.1 Sen or Selection............................................................................................................................................. 14

6.2 Depth Range Selection................................................................................................................................... 14

6.3 Link ............................................................................................................................................................... 15

7 Calibration.................................................................................................................................................................. 16

7.1 Set Zero.......................................................................................................................................................... 16

7.2 Set Span......................................................................................................................................................... 16

8 Scraper Clearance..................................................................................................................................................... 17

8.1 Bridge Clearance Control................................................................................................................................ 17

9 Output ...................................................................................................................................................................... 18

9.1 Analogue Output............................................................................................................................................. 18

9.2 Limit Relay...................................................................................................................................................... 18

10 Maintenance............................................................................................................................................................ 19

10.1 General Precaution ..................................................................................................................................... 19

10.2 Routine Maintenance.................................................................................................................................... 19

10.3 Removal of the Printed Circuit Board A embly............................................................................................19

10.4 Sen or replacement...................................................................................................................................... 21

11 Fault Finding............................................................................................................................................................. 22

11.1 Symptom: Digital di play change but doe not relate correctly to the en or po ition.................................22

11.2 Symptom: The en or drive to the top limit................................................................................................. 23

11.2.1 Fault: Sen or i fouled............................................................................................................................. 23

11.2.2 Fault: Faulty External UP Switch............................................................................................................. 23

103370IM I ue 10 Date 19/03/2018 Page 3 of 30