SoliTechw² IR Sensor

Table of Contents

1 Introduction.................................................................................................................................................................. 5

1.1 SoliTechw² IR Sensors..................................................................................................................................... 5

1.1.1 Light Absorption........................................................................................................................................... 5

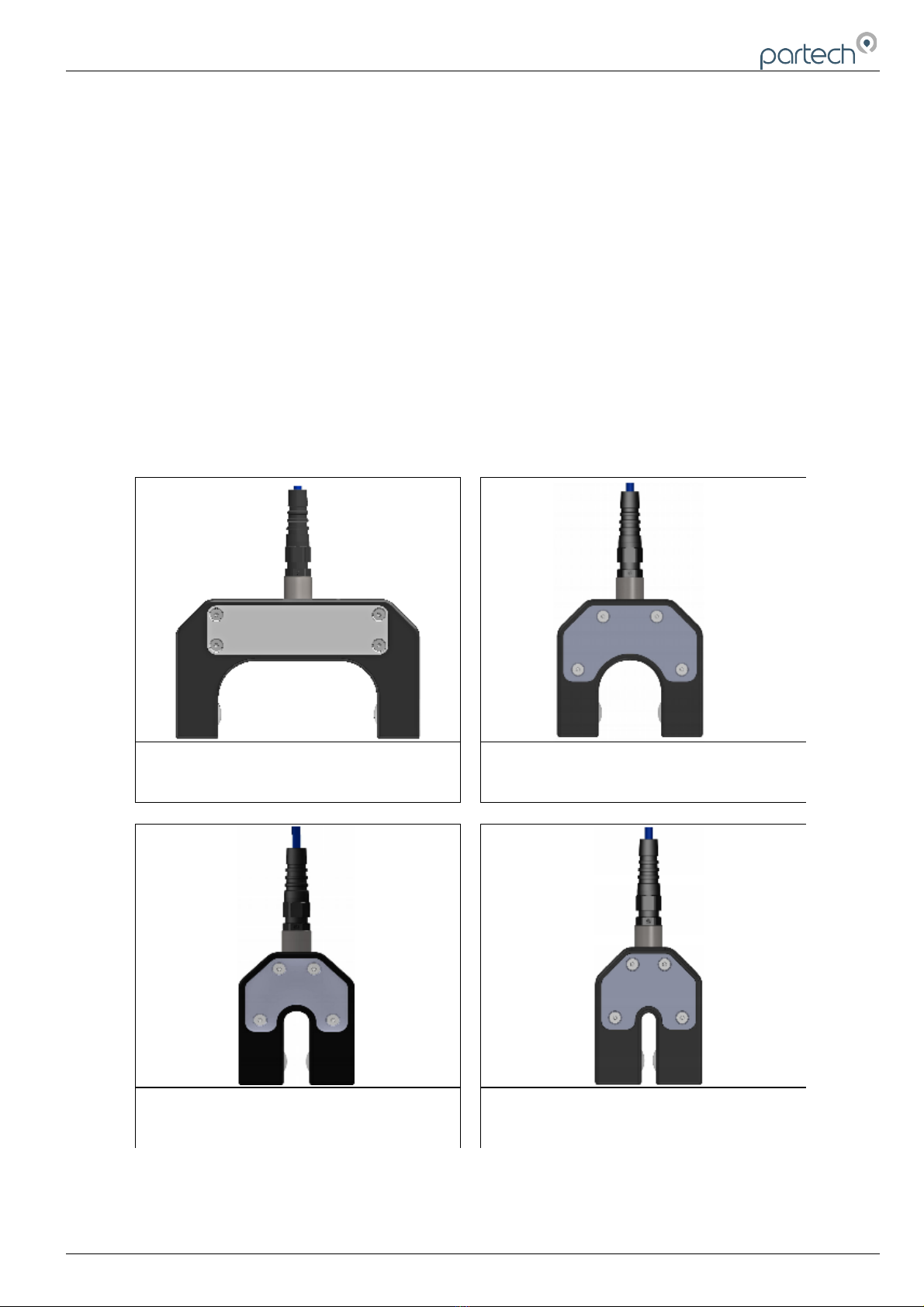

1.1.2 Mounting Options......................................................................................................................................... 6

2 Mechanical Installation................................................................................................................................................. 7

2.1 Location............................................................................................................................................................ 7

2.2 Partech Brackets............................................................................................................................................... 7

2.3 Customer Supplied Brackets............................................................................................................................. 7

3 Electrical Installation.................................................................................................................................................... 8

3.1 Cable Routing................................................................................................................................................... 8

3.2 Connection Details............................................................................................................................................ 8

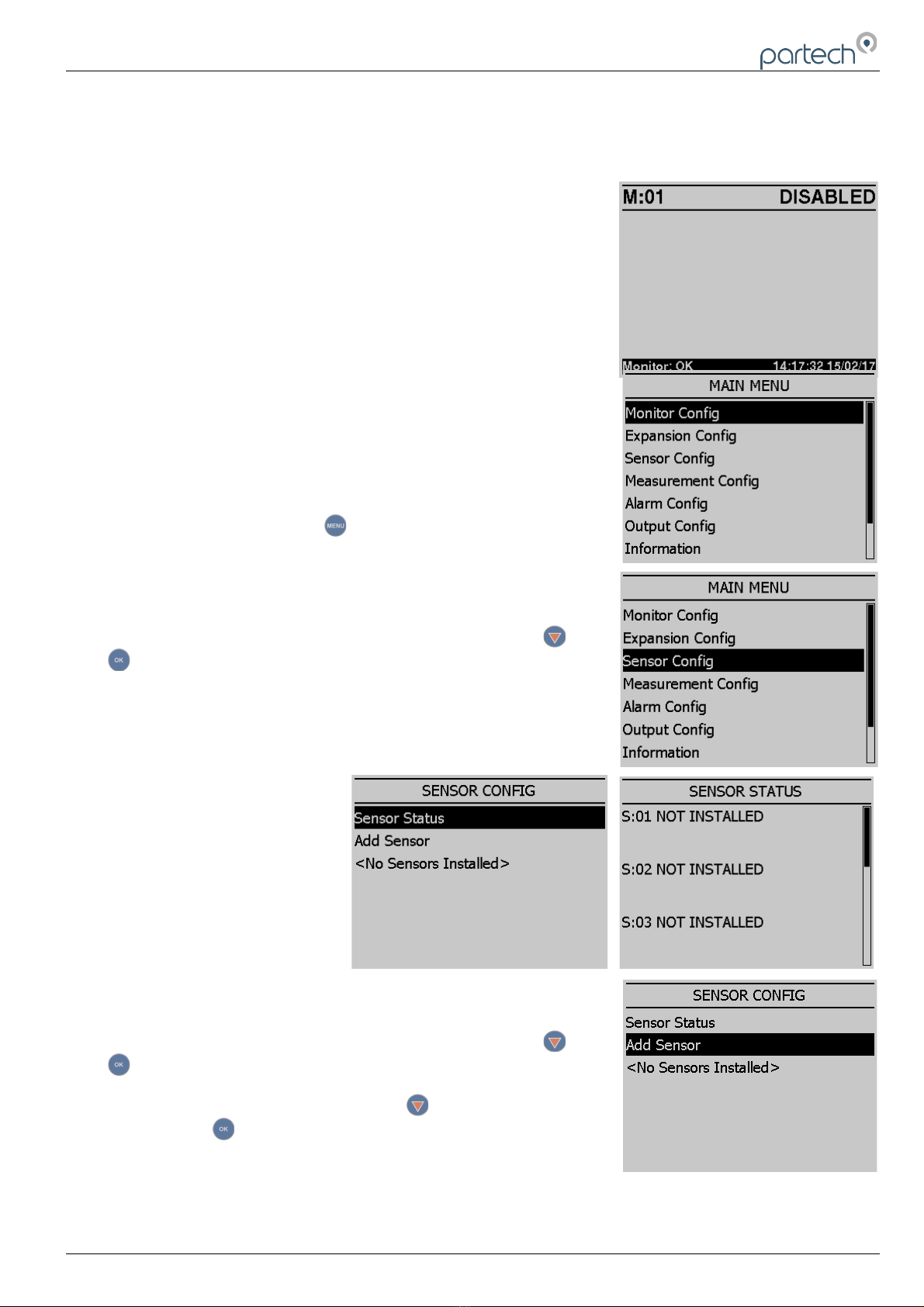

1 SoliTechw² IR Sensor Configuration............................................................................................................................ 9

1.1 Sensor Config................................................................................................................................................... 9

1.2 Sensor Status................................................................................................................................................... 9

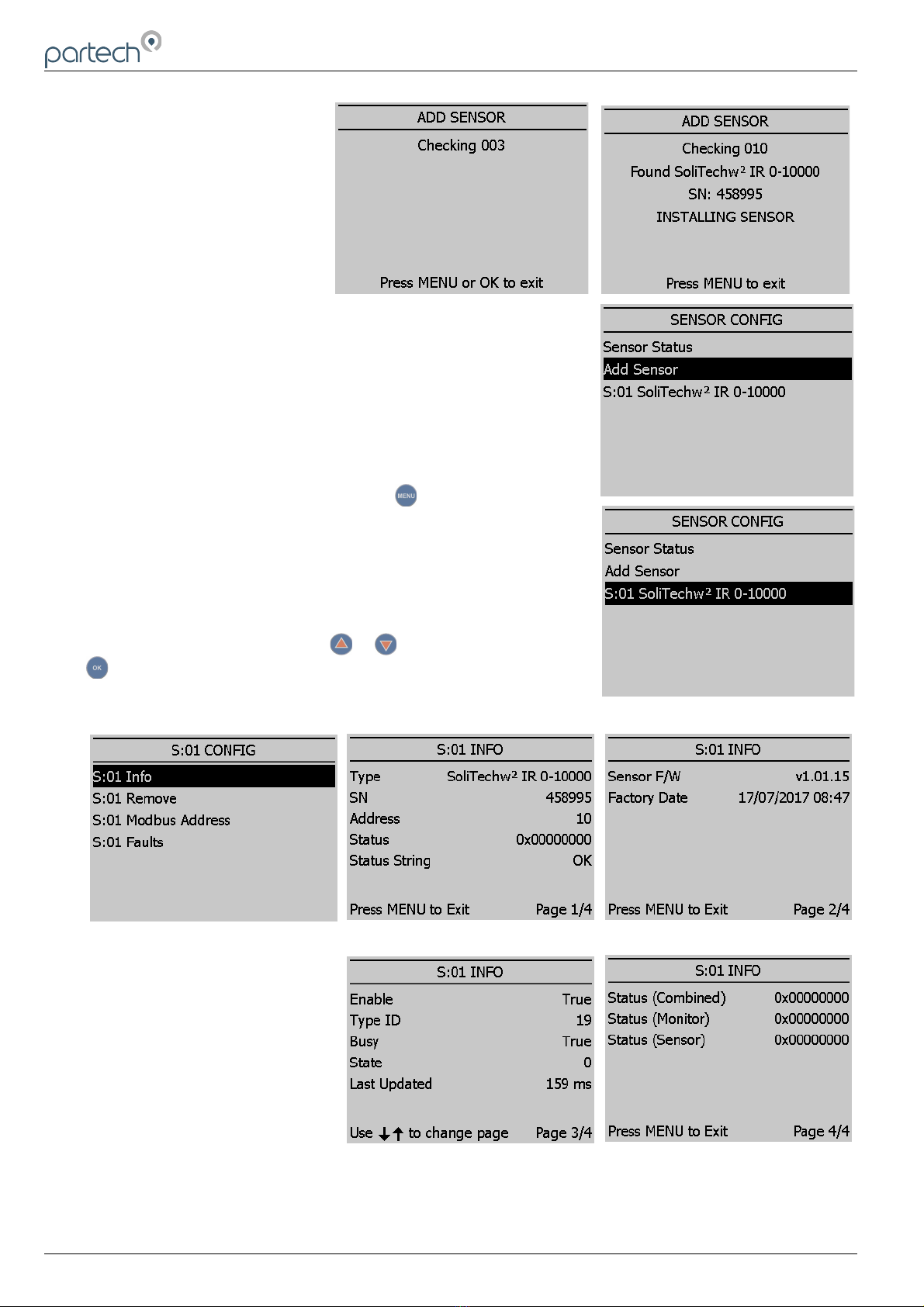

1.3 Add Sensor....................................................................................................................................................... 9

1.1 S:0x SoliTechw² IR 0-xxxxx............................................................................................................................ 10

1.1.1 S:0x Info...................................................................................................................................................... 10

1.1.2 S:0x Remove.............................................................................................................................................. 11

1.1.3 S:0x Modbus Address................................................................................................................................. 11

2 Measurement Configuration....................................................................................................................................... 12

2.1 Measurement Config....................................................................................................................................... 12

2.1.1 Measurement Status................................................................................................................................... 12

2.1.2 Add Measurement....................................................................................................................................... 12

2.2 M:0x – Measurement Channel........................................................................................................................ 13

2.2.1 M:0x Info..................................................................................................................................................... 13

2.2.2 M:0x Title.................................................................................................................................................... 14

2.2.3 M:0x Set Zero............................................................................................................................................. 14

2.2.4 M:0x Set Cal............................................................................................................................................... 14

2.2.5 M:0x Take Sample...................................................................................................................................... 14

2.2.6 M:0x Sample Result.................................................................................................................................... 14

2.2.7 M:0x Averaging........................................................................................................................................... 14

2.2.8 M:0x Remove.............................................................................................................................................. 15

2.2.9 M:0x Display Position.................................................................................................................................. 15

2.2.10 Restore Defaults....................................................................................................................................... 15

3 Calibration.................................................................................................................................................................. 16

3.1 Preparation for Calibration.............................................................................................................................. 16

3.2 Calibration Frequency..................................................................................................................................... 16

3.3 Calibration Solutions....................................................................................................................................... 16

3.4 Zero Calibration.............................................................................................................................................. 16

3.5 Span Calibration............................................................................................................................................. 17

3.6 Take Sample................................................................................................................................................... 18

3.7 Sample Result................................................................................................................................................. 18

228655IM-Iss05 Issue Date 25/08/2020 Page 3 of 26