OxyTechw² GAL Instruction Manual

Table of Contents

1 Foreword........................................................................................................................................................ 5

2 Introduction.................................................................................................................................................... 6

2.1 Manual Conventions.............................................................................................................................. 6

2.2 WaterWatch² Trademark........................................................................................................................ 6

2.3 Sco e of Manual.................................................................................................................................... 6

2.4 External Sensors................................................................................................................................... 6

3 Safety Precautions......................................................................................................................................... 7

3.1 General.................................................................................................................................................. 7

3.2 Electrical installation.............................................................................................................................. 7

3.3 O erating............................................................................................................................................... 7

3.4 Service and Maintenance...................................................................................................................... 7

3.5 End of Life Dis osal............................................................................................................................... 8

4 OxyTechw² GAL Sensor............................................................................................................................... 9

4.1 Sensor Overview................................................................................................................................... 9

4.2 Storage.................................................................................................................................................. 9

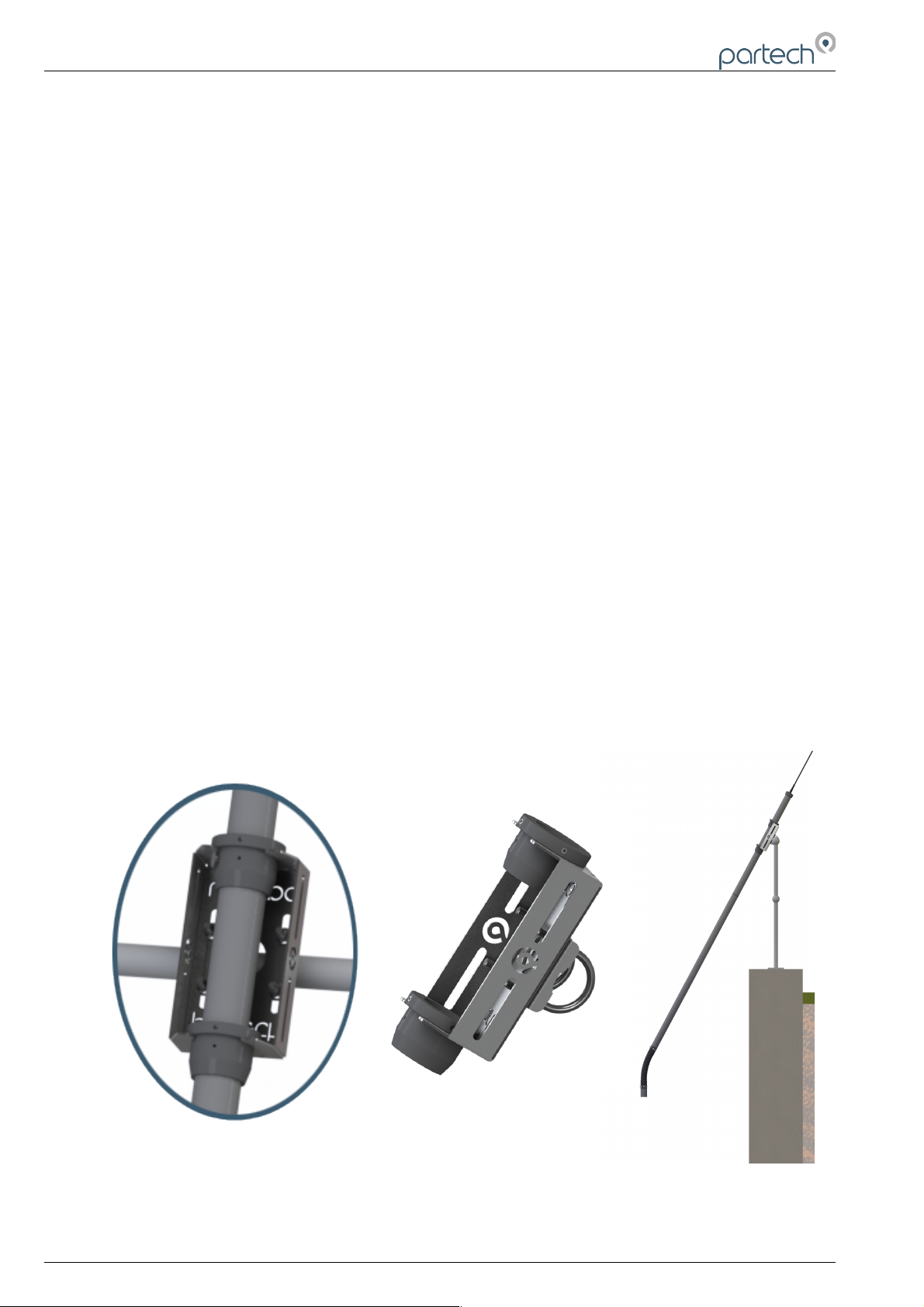

5 Mechanical Installation................................................................................................................................. 10

5.1 Mounting O tions................................................................................................................................. 10

5.2 Mounting Shaft..................................................................................................................................... 10

5.3 Handrail and Wall Brackets.................................................................................................................. 11

5.4 Customer Su lied Brackets............................................................................................................... 11

6 Electrical Installation.................................................................................................................................... 12

6.1 Electrical Installation............................................................................................................................ 12

6.2 Sensor Connections............................................................................................................................ 12

6.3 Extending Sensor Cables.................................................................................................................... 13

7 Sensor Configuration................................................................................................................................... 14

7.1 Sensor Config...................................................................................................................................... 14

7.2 Sensor Status...................................................................................................................................... 14

7.3 Add Sensor.......................................................................................................................................... 14

7.4 S:0x OxyTechw² GAL.......................................................................................................................... 14

7.4.1 S:0x Info....................................................................................................................................... 15

7.4.2 S:0x Remove............................................................................................................................... 15

7.4.3 S:0x Modbus Address.................................................................................................................. 15

8 Measurement Configuration......................................................................................................................... 16

8.1 Measurement Config............................................................................................................................16

8.2 Measurement Status............................................................................................................................ 16

8.3 Add Measurement............................................................................................................................... 16

8.4 M:0x – Measurement Channel............................................................................................................. 17

8.4.1 M:0x Info...................................................................................................................................... 17

8.4.2 M:0x Title..................................................................................................................................... 17

224083IM-Issue 04 20/03/2018 Page 3 of 28