L55 and IL55BV2 Sensor Instruction Manual

Table of Contents

1 Introduction...................................................................................................................................................................4

1.1 IL55/IL55BV2 Sensors.......................................................................................................................................4

1.2 IL55BV2 Sensor.................................................................................................................................................4

1.3 7200 Monitor......................................................................................................................................................4

2 Installation.....................................................................................................................................................................5

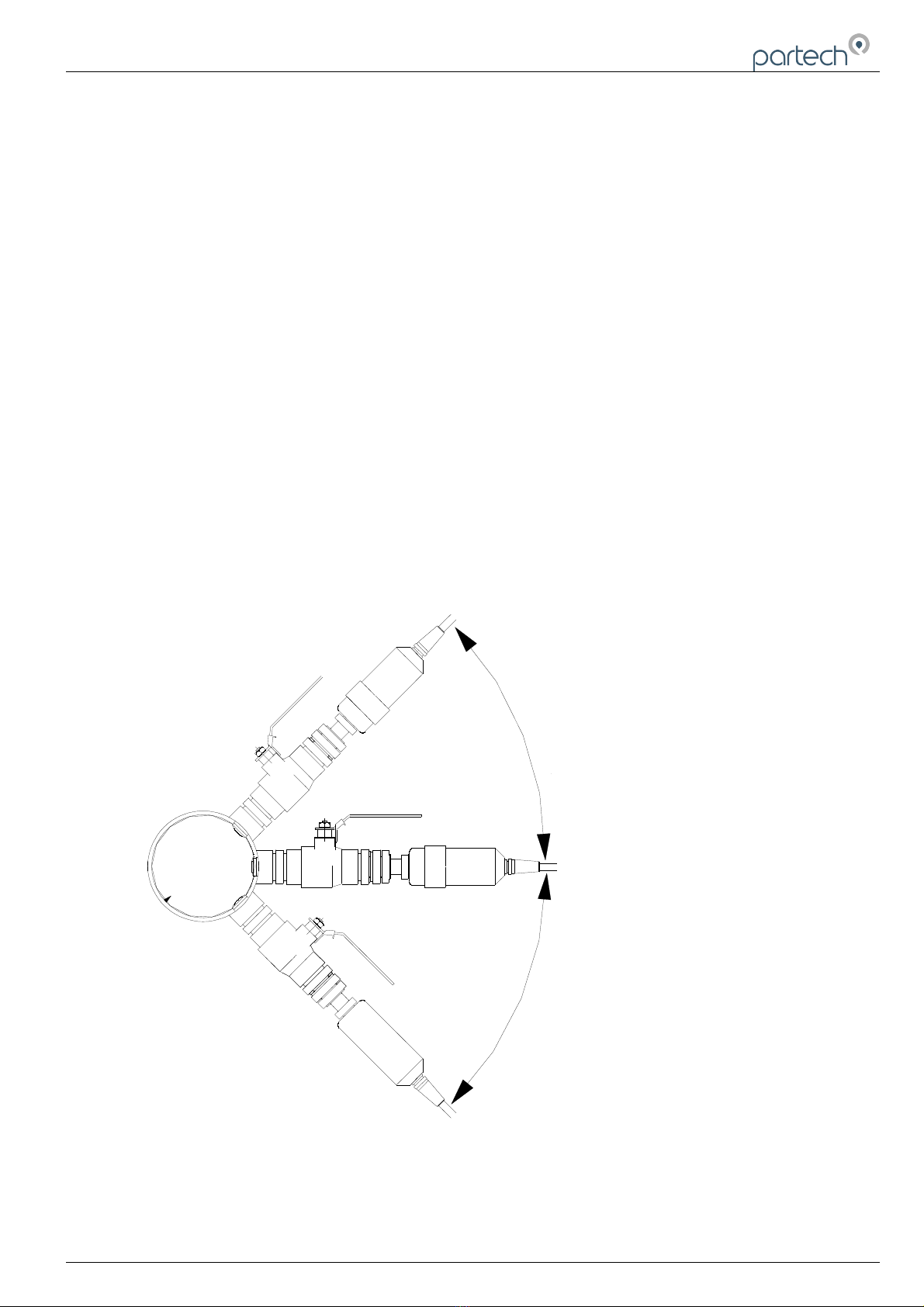

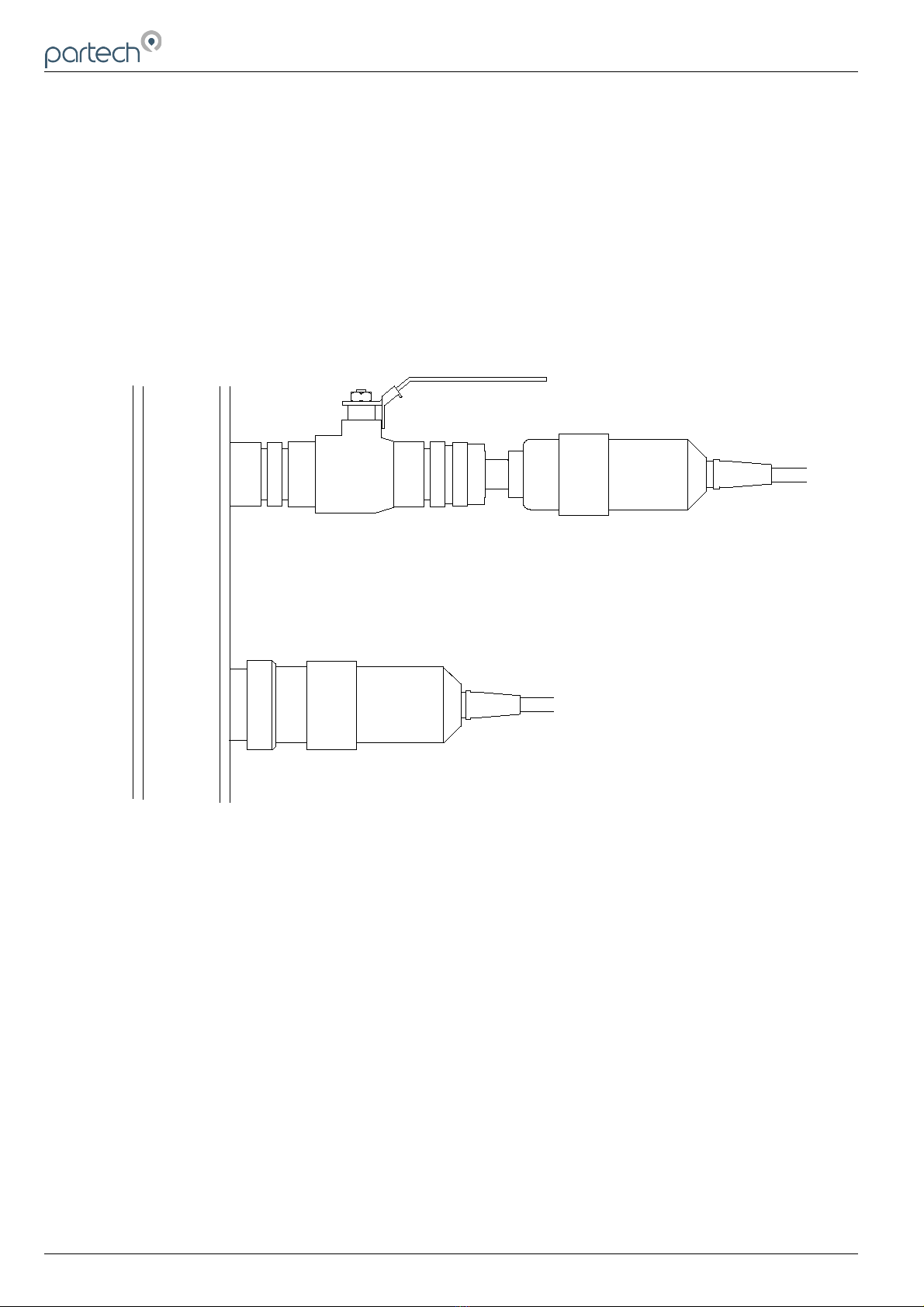

2.1 Horizontal Pipelines...........................................................................................................................................5

2.2 Vertical Pipelines...............................................................................................................................................6

2.3 Mounting Boss Installation.................................................................................................................................6

3 Electrical Installation.....................................................................................................................................................7

3.1 Cable Routing....................................................................................................................................................7

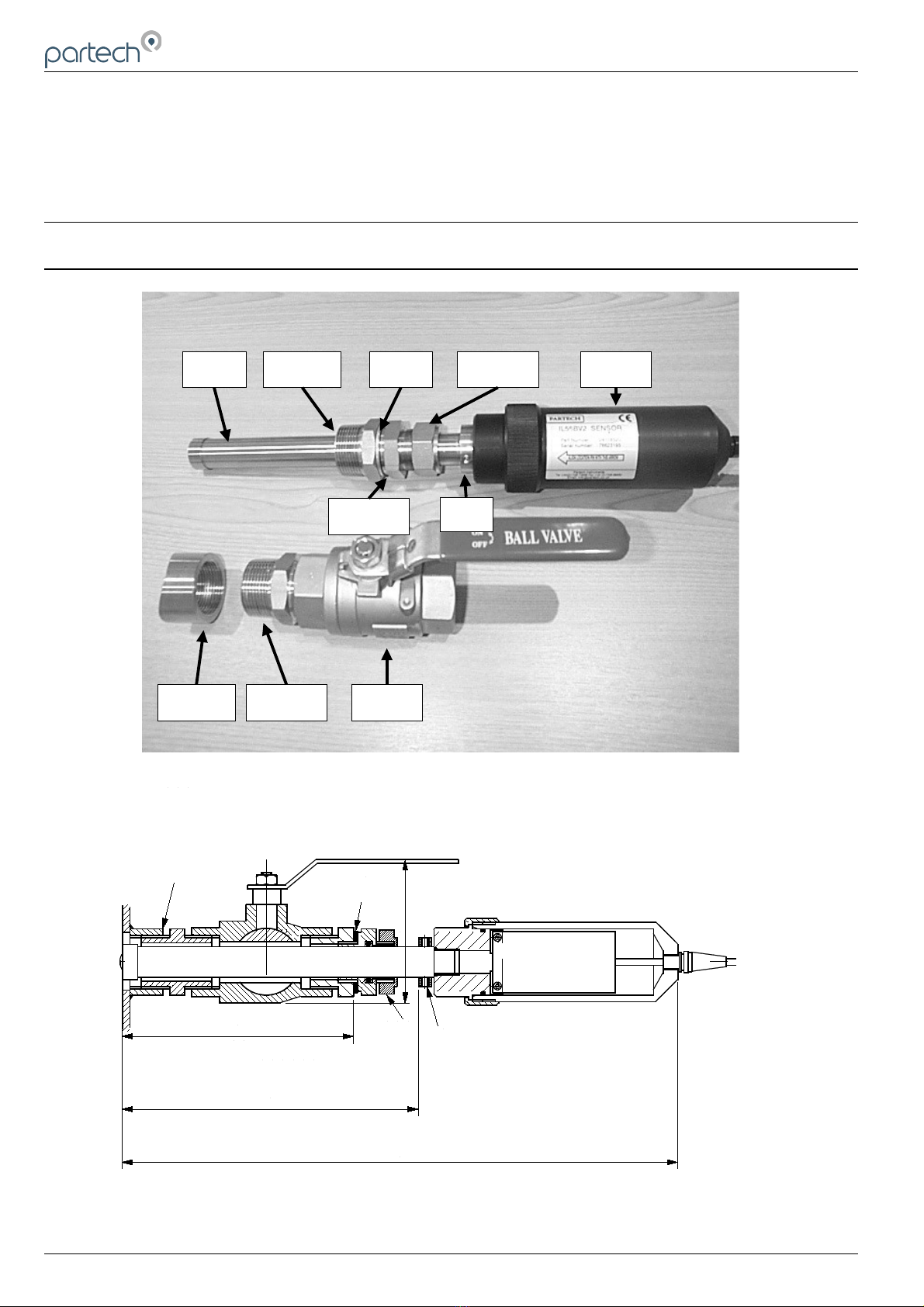

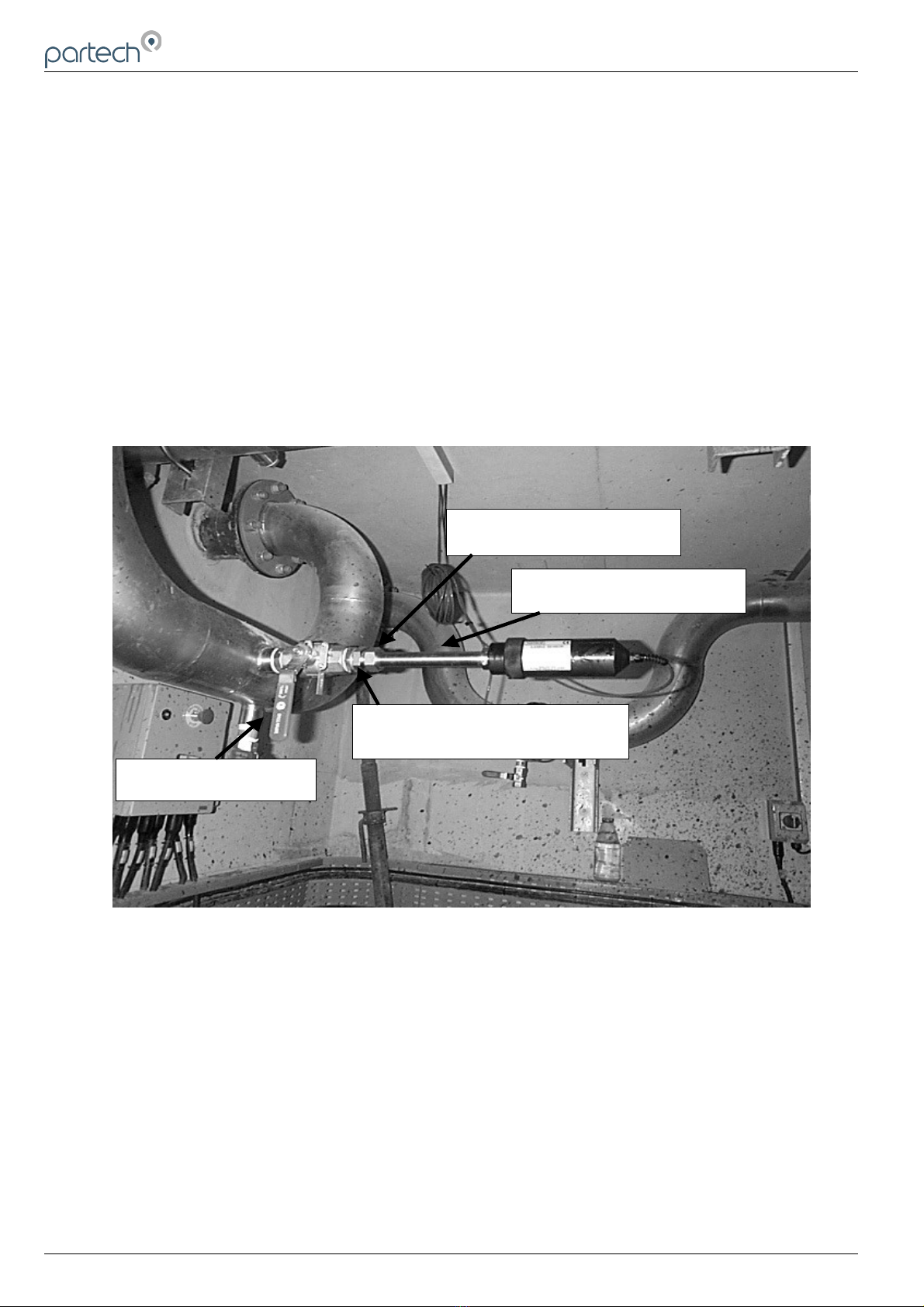

4 IL55BV2 Sensor............................................................................................................................................................8

4.1 Installation Procedure........................................................................................................................................9

4.2 Sensor Removal..............................................................................................................................................10

5 IL55 Sensor.................................................................................................................................................................11

5.1 Sensor Removal..............................................................................................................................................12

6 Setup & Calibration.....................................................................................................................................................13

7 Maintenance...............................................................................................................................................................14

7.1 Sensor Cleaning..............................................................................................................................................14

7.2 Inspection.........................................................................................................................................................14

7.3 Fault Finding....................................................................................................................................................14

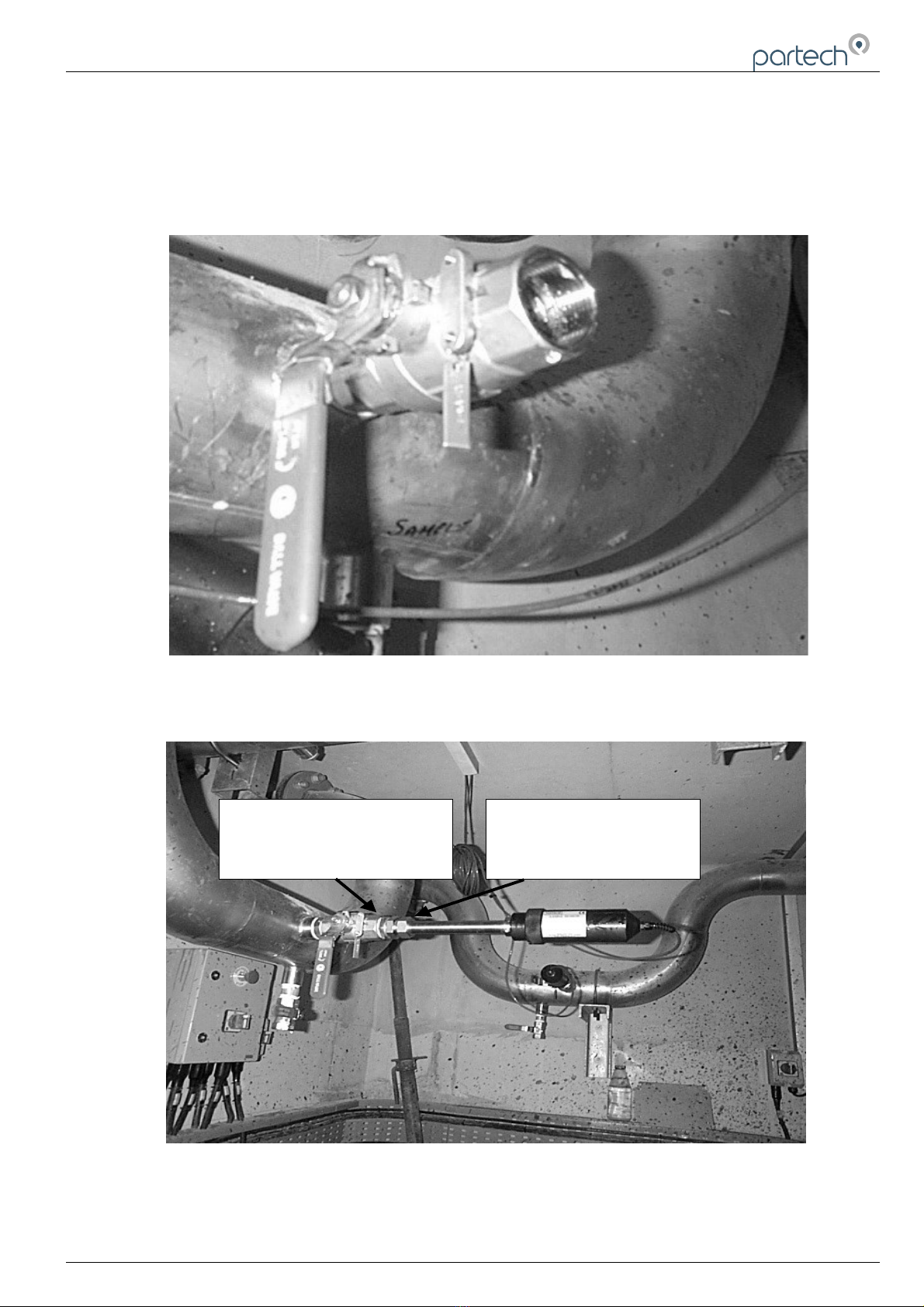

8 Application Example: Sludge Density Monitor............................................................................................................15

9 Spare Parts.................................................................................................................................................................16

9.1 Sensors............................................................................................................................................................16

9.2 Mounting Accessories......................................................................................................................................16

9.3 Miscellaneous..................................................................................................................................................16

10 Technical Support.....................................................................................................................................................17

10.1 Returning Equipment for Repair.....................................................................................................................17

11 Technical Specification (should be last section)........................................................................................................18

12 Appendix 1: Preparation of Formazin Turbidity Standard..........................................................................................19

12.1 Health & Safety Precautions..........................................................................................................................19

12.2 Method of Preparation...................................................................................................................................19

12.3 Preparation of Dilution’s.................................................................................................................................19

12.4 Calibration......................................................................................................................................................19

12.5 Storage Life....................................................................................................................................................19

13 Appendix 2: Fuller's Earth.........................................................................................................................................20

163790IM-Iss05 Issue Date 11/05/210 Page 3 of 22