8 | Page

adjusted after the switches are mounted and

adjusted.

Refer to arcing horn assembly drawing

supplied with the order for detailed

information.

Step 14—Installation of Corona Rings and

Balls

If corona rings and balls have been supplied,

install these components as shown on the single

pole drawings.

Important: Prepare areas where ring supports

contact switch parts as per instructions for

aluminum-to-aluminum connections on this

page.

Step15—Final Checks

The completed 3-pole installation should be

checked for the following:

1. In the open position, the blades should be

between 90° to 93°.

2. In closing, blades should make central entry

into their jaws at approximately the same

time.

3. In the closed position, all blades must be in

full contact with jaws.

4. All bolts are tight and all cotter pins are bent

adequately.

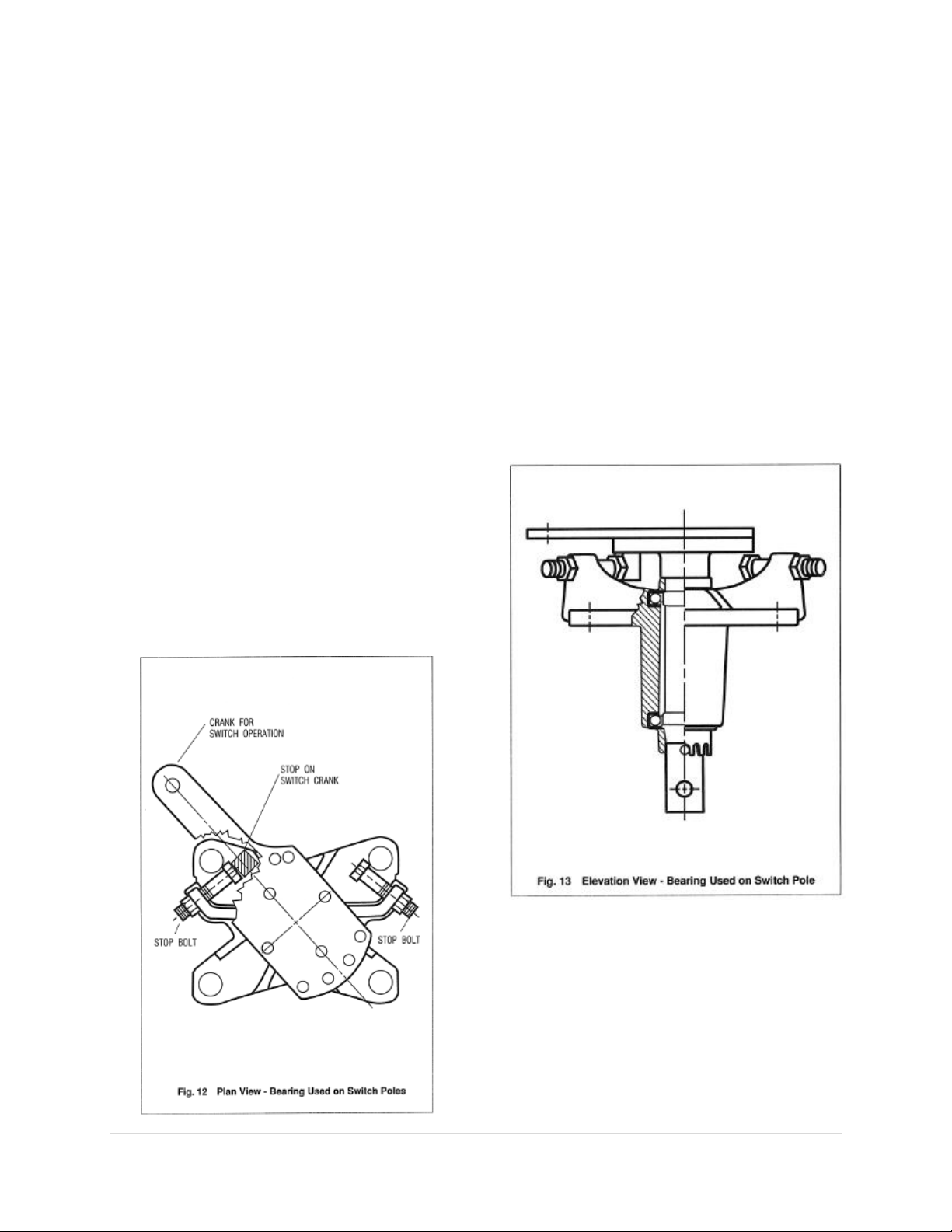

5. The single poles are held against or nearly

against their individual rotor bearing stops in

both the open and closed positions and also

the stops on the offset bearing.

6. Operating effort required to operate the

switch is not excessive.

Terminal Connections

The aluminum surface of the terminal

connection provides for easy current transfer.

Notice: In cases where a copper conductor is

used, bolt a tinned terminal clamp (if available)

to the aluminum switch terminal pad.

If a non-tinned terminal clamp is used, apply a

liberal amount of electrical joint grease at the

joint and all over the pad of the fitting.

To connect aluminum – to - aluminum

terminals:

1. Clean all contact surfaces of conductors and

fittings using a stiff wire brush to remove

heavy oxide coatings until the aluminum

finish is visible and restored.

2. Coat these now clean contact areas with a

liberal amount of corrosion inhibitor such as

NO-OX-ID”A Special” or No. 2 EJC.

3. Abrade the contact surface through the

corrosion inhibitor again using the stiff wire

brush.

Notice: Do not remove the compound.

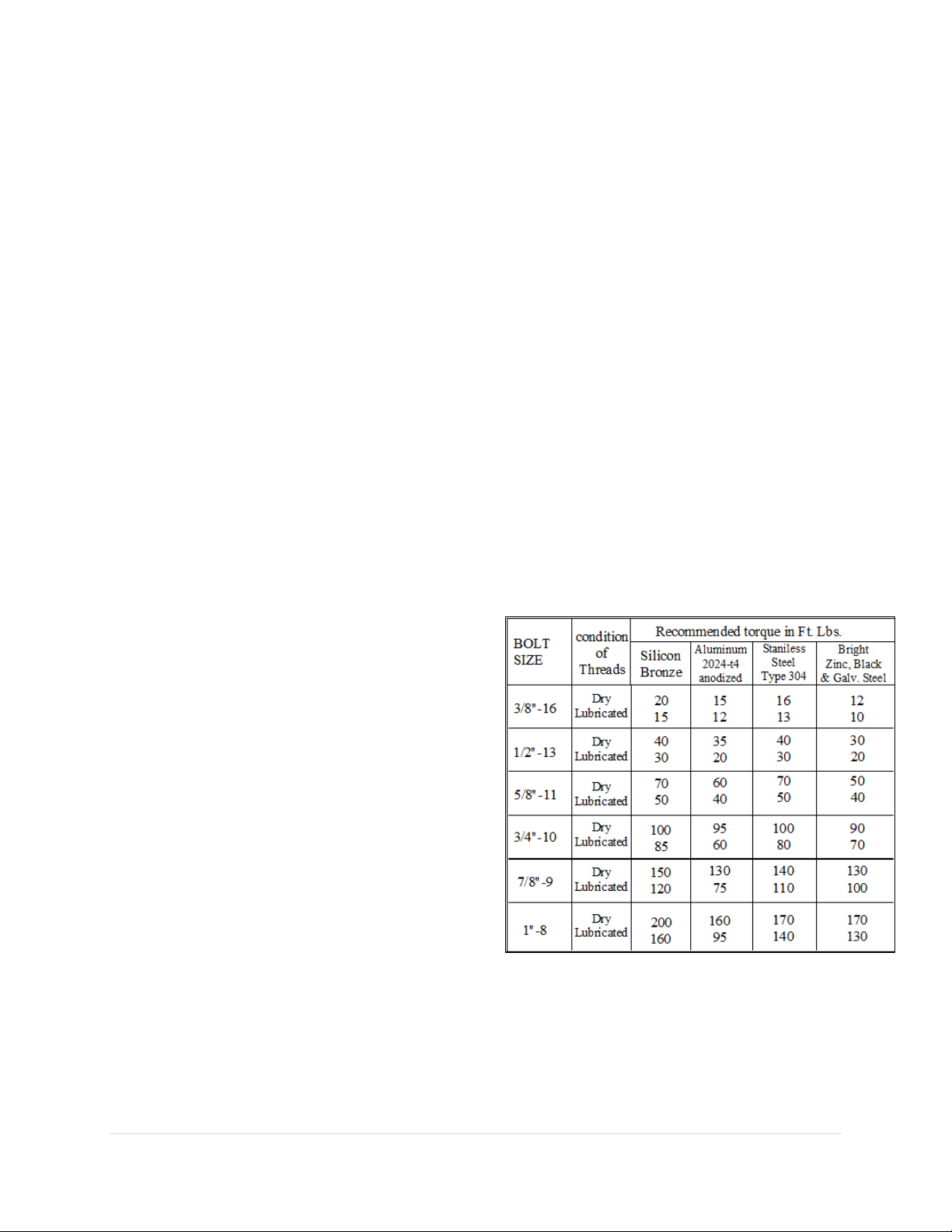

4. Connect the terminals and tighten bolts

To connect copper-to-aluminum terminals:

1. Except for plated surfaces, clean all contact

surfaces of conductors and fittings using a

stiff wire brush to remove heavy oxide

coatings until the aluminum finish is visible

and restored.

2. Prepare any bare copper surfaces in the

usual manner.

3. Coat these now clean contact areas with a

liberal amount of corrosion inhibitor such as

NO-OX-ID “A Special” or no. 2 EJC.

4. Abrade the contact surface through the

corrosion inhibitor using a stiff wire brush.

Notice: Do not remove the electrical joint

grease.

5. Connect the terminals and torque the bolts

as per Table 1.

MAINTENANCE

WARNING

Before servicing the switch, be sure it is

disconnected from all electric power

sources and properly grounded.