4 | Page

contacts on the ends of the blade should approach

the jaw fingers at the same time and the blade

should hit both stops at about the same time. Also

the blade contacts, as they enter the jaw contacts,

should not rub the jaw fingers. If the blade rubs

the top fingers on one jaw and the bottom fingers

on the other, then a little adjustment at the bottom

of the center insulator stack with the shims of

leveling screws provided will usually result in

proper entry. If the blade rubs the top fingers on

both jaws or the bottom fingers on both jaws, then

a change in elevation is required and can be

achieved at the center stack of jaw stacks by using

the same shims of leveling screws. At this point,

recheck the blade penetration to see that the blade

hits both stops at the same time. If it doesn’t, the

shims and leveling screws will provide for

necessary adjustment.

When blade entry is satisfactorily achieved then

check to see if all jaw fingers are contacting the

blade end contact. If necessary, adjust with either

shim or leveling screws at the base of the jaw

insulator stacks. If it is expected that the

conductors to be attached to the terminal pads will

impose an appreciable force, it is recommended

that the jaw insulator columns be adjusted so that

the jaw fingers end up slightly off center on the

blade contact in a direction opposite to the

expected force. The jaw mounting bolts may now

be tightened.

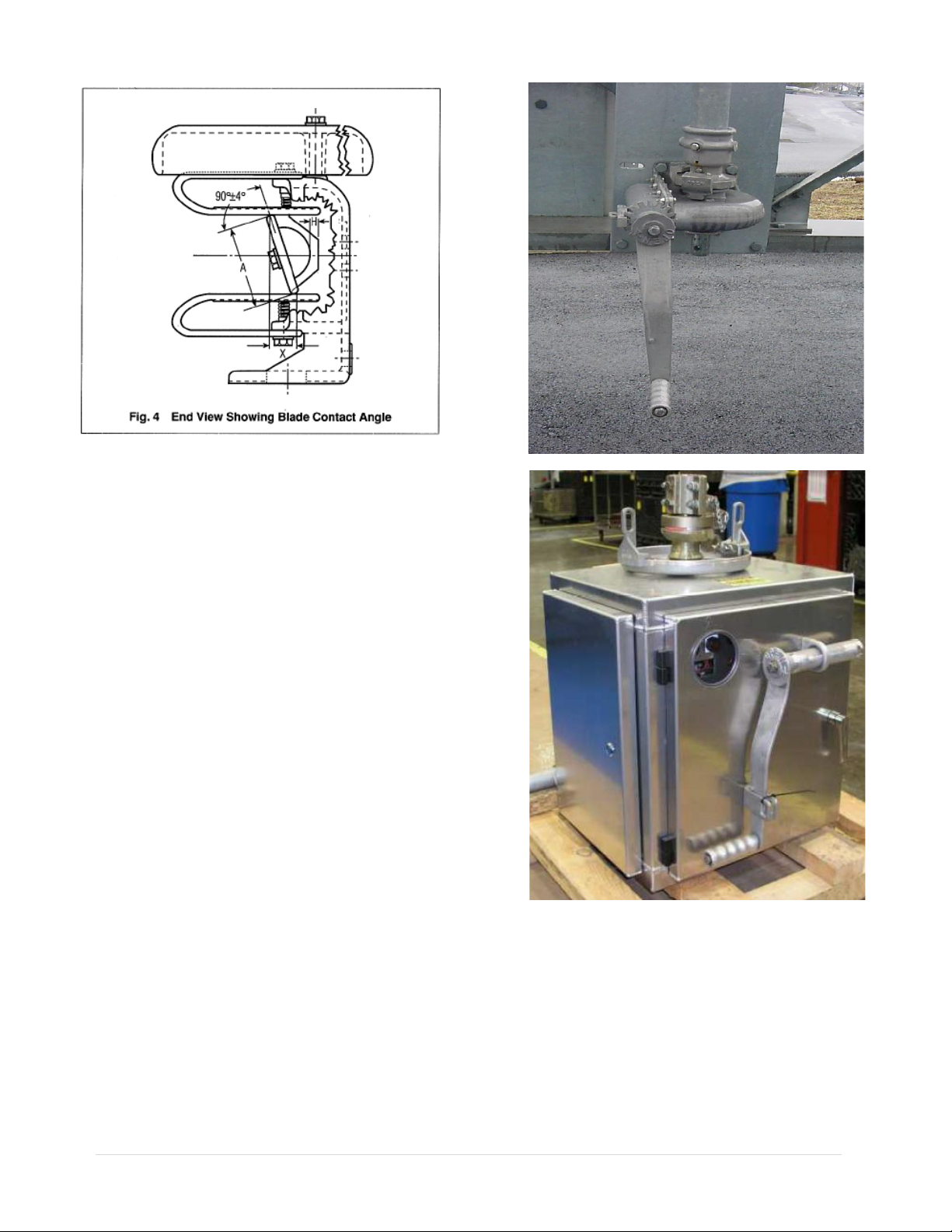

6—2 Blade Contact Angle

The blade contacts can be at a slight angle in the

closed position, (Fig. 4). An allowable contact

angle of 4 degrees permits an (dimension X) is

1/16” for each 1” of contact width. Example: If

contact width (A) is 4 1/2”, then dimension (X)

can be as much as 9/32” and still be within the

plus or minus 4 degree tolerance. Fig. 4 shows the

top of the blade contact leaning to the left. It is

also permissible for the top of the blade contact to

lean to the right as long as the 4 degree angle is

not exceeded. It is common to have both

situations on one three-pole switch. In fact, after

all three poles have been adjusted in the open

position, and then closed, you may find that one

pole will be high on the right, one fairly level and

one high on the left. This is due to many variables

and tolerances plus the free play or clearance in

pin connections of all the switches and control

parts.

6—3 Blade Engagement When Switch is Closed

Due to varying friction and deflection, the distance

between the blade and its stop (dimension H in Fig.

4), with the switch fully closed, may vary from 0”

to 1”. Insulator stacks can be adjusted to achieve

this. It is not usually possible to get this dimension

to be equal on all poles of a three-pole switch.

6—4 Stops on Current Carrying Parts

The stops on the blade mechanisms are set at the

factory and seldom require any adjustment.

However, if these stops prevent the blades from

turning to an acceptable closed of open position,

they should be re-adjusted.

After each pole has been adjusted, the open and

close stop bolts at the base of the rotating insulator

column should be set.

Step 7—Install Interphase and Offset Crank Rods

With all blades in the closed position, install the

interphase rods and offset crank rod as follows:

a. Lengthen the interphase rods that are in

compression during opening, as much as

possible, yet allowing for the pins to be

inserted.

b. On the rods that are in tension during opening,

shorten them as much as possible, yet allowing

for the pins to be inserted.

c. The offset crank rod between the outboard

bearing and the driven switch should be

handled the same way

Step 8—Install Vertical Operating Pipe

Attach vertical operating pipe to rotor bearing shaft, of

to offset rotor bearing shaft, with coupling pins

supplied. At this point, check drawings for accessory

equipment (auxiliary switches, mechanical interlocks,

position indicators, ground straps, etc.) which mounts

on vertical operating pipe and install before continuing

installation. The vertical pipe is predrilled at one end

for a 5/8” diameter pin, two of which are shipped,

together with a coupling, in a bad, for connection to

the offset bearing shaft (or on the pole unit rotor

bearing in the case of direct connection switches)