5

IMPORTANT SAFETY WARNINGS

WARNING

Serious injury or death may occur from a re caused by a mufer spark.

Serious injury or death may occur if system safety's are not properly maintained.

• A spark arrester must be added to the mufer of this engine when using on land covered with any

ammable agricultural crop (hay and grain), and if they are used in or near brush or forested areas. The

arrester must be maintained in effective working order by the operator of the equipment. In the state

of California, the above is required by law. (Section 4442 and 4443 of the California Public Resources

Code.) Other states/provinces may have similar laws. Federal laws apply on Federal lands.

• This pressure washer has a Safety Relief Valve . This should never be altered, modied, removed or

made inoperative. If the device fails, replace immediately with genuine manufacturer replacement part.

WARNING

Serious injury or death may occur from inhaling engine/burner exhaust or dangerous vapors.

The engine exhaust from this product contains chemicals known to the State of California to

cause cancer, birth defects, or other reproductive harm.

• Never operate this pressure washer in an enclosed area. Always ensure there is adequate ventilation

(fresh outside air) for breathing and combustion. This will prevent the buildup of dangerous carbon

monoxide gases. Beware of poorly ventilated areas, or areas with exhaust fans which can cause poor

air exchange. This unit should only be used outdoors to ensure ventilation is never an issue.

• Follow all safety instructions provided with the materials you are spraying. Use of a respirator may be

required when working with some materials. Do not use this pressure washer to dispense hazardous

detergents.

WARNING

Serious injury or death could occur from high pressure spray penetrating the skin.

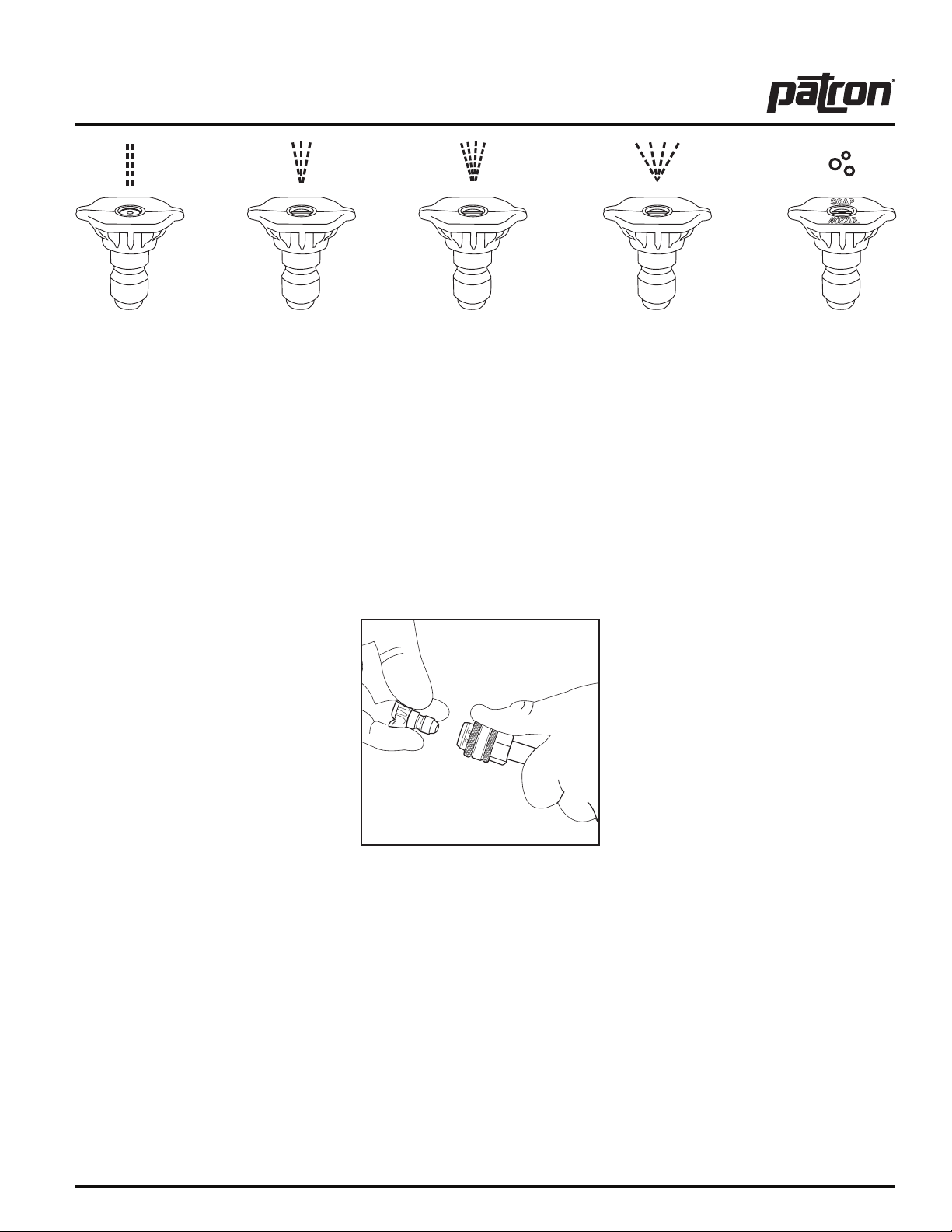

• Keep clear of nozzle and spray! Never put your hand, ngers or body directly over the spray nozzle.

• Do not direct discharge stream at self, other persons, or pets.

• This product is to be used only by trained operators.

• Always keep operating area clear of other people.

• Do not allow children to operate this unit or be in the vicinity while you operate it.

• Seek emergency medical care if spray seems to have penetrated the skin. Do not treat as a simple cut!

• High pressure hoses and fuel lines should be inspected daily for signs of wear. If evidence of failure

exists, promptly replace all suspect hoses and fuel lines to prevent the possibility of injury from the high

pressure spray. If a hose or tting is leaking, do not place your hand on the leak.

• Never operate the gun with the trigger held in the open position. To prevent accidental discharge, the

trigger gun should be securely locked when not in use.

• Before removing the spray nozzle or servicing the unit, always shut the unit off and pull the trigger of the

gun to release trapped pressure (even after you shut off the unit, there is high pressure water left in the

pump, hose and gun until you release it by pulling the trigger the gun).

WARNING

Serious injury or death may occur from contact with electricity.

• Do not direct spray on or into electrical installations of any kind! This includes electrical outlets, light

bulbs, fuse boxes, transformers, and the unit itself.

• Do not allow metal components of the pressure washer to come in contact with live electrical

components.