pba Setrite User manual

Pratt Burnerd America

Setrite Self Centering

Scroll Chucks

5" (125mm) - 15" (400mm)

Important: R ad this manual b for using this product:

The Setrite chuck is a durable, steel bodied self centering chuck with a concentricity adjustment feature built

into the body. The front body can be re-aligned in relation to the machine spindle using the various adjusting

screws to the rear of the chucks periphery, workpieces can be trued to within a repeat concentricity of

0.013mm or for optimum accuracy (0.005mm) each component can be trued individually. All components of

the chucks are manufactured from steel, with the scrolls being manufactured in an exceptionally tough alloy

steel and are hardened and ground for accuracy and durability.

Pratt Burn rd Am rica, 3977 Emerald Dr., Kalamazoo, MI 49001

Phone 800-253-0820, Fax No. 269-384-3201 Web Page www.prattburnerd.com e-mail info@prattburnerd. com

1

For ensuring the safe and correct use of this product, please read and pay attention to all the instructions

and keep this manual so that it can be retrieved whenever needed.

1. Saf ty Al rt Symbols

2. Qualifi d Op rators

Pratt Burnerd clamping equipment may be set up,

operated and maintained by those only who are

trained to do so. Persons handling clamping

equipment who do not possess the necessary

training run the risk of potential injury from the

clamping motion and the forces generated.

3. Maximum

P rmitt d Sp d

The maximum permitted speed may only be run at

maximum permitted actuation force and using a

perfectly operating chuck. For maximum permitted

speed ratings see page 3.

4. Exc ding Th

P rmitt d Sp d

The centrifugal forces caused by excessive

rotational speeds may result in individual parts of the

clamping device becoming detached or the work

piece being ejected, with the potential to

cause harm to those in the close vicinity,

considerable damage to the machine and the chuck

itself. The maximum speed and the operating

force/pressures are embossed on the body and may

not be exceeded for the reasons mentioned above.

5. Clamping Rang

The maximum clamping range may not be

exceeded, the lack of sufficient engagement

between the clamping jaw and the component part

could cause a negative effect on machining, work

piece ejection or injury to the operator.

For clamping ranges see page 4.

To check the chucking force, it is recommended

using the Pratt Burnerd Radio Frequency Grip

meter. For optimum performance the clamping

force should be checked at regular intervals, the

intervals are dependent on the application, for

more information contact Pratt Burnerd.

6. Mounting

Clean any excess protective grease from the

chuck and inspect for any damage which may

have occurred in transit. Before mounting the

chuck ensure the machine spindle is running

true by checking the chuck locating faces both

radial and axial directions using a dial indicator

as shown in figure 1. The maximum error should

not exceed 0.005mm full indicator movement

(FIM). Also check the mounting faces are clean

and undamaged. If the chuck is supplied with a

separate mounting adaptor, this should match

the machine spindle and should be secured to it

using the fasteners provided. For torque values

see page 3.

Check the chuck mounting spigot and face for

true running (Fig 2).

The adaptor should run within 0.01mm FIM on

the Face and 0.02mm on the diameter. Wipe

the chuck location faces clean and mount the

chuck to the spindle and adaptor using screws

provided. It is good practice to check the

chuck’s outside diameter and face for the true

running (Fig 3). The chuck may be assessed for

gripping accuracy (Fig 3) by using an accurate

test bar gripped in the chuck and the readings

compared with the particular chucks accuracy

standard.

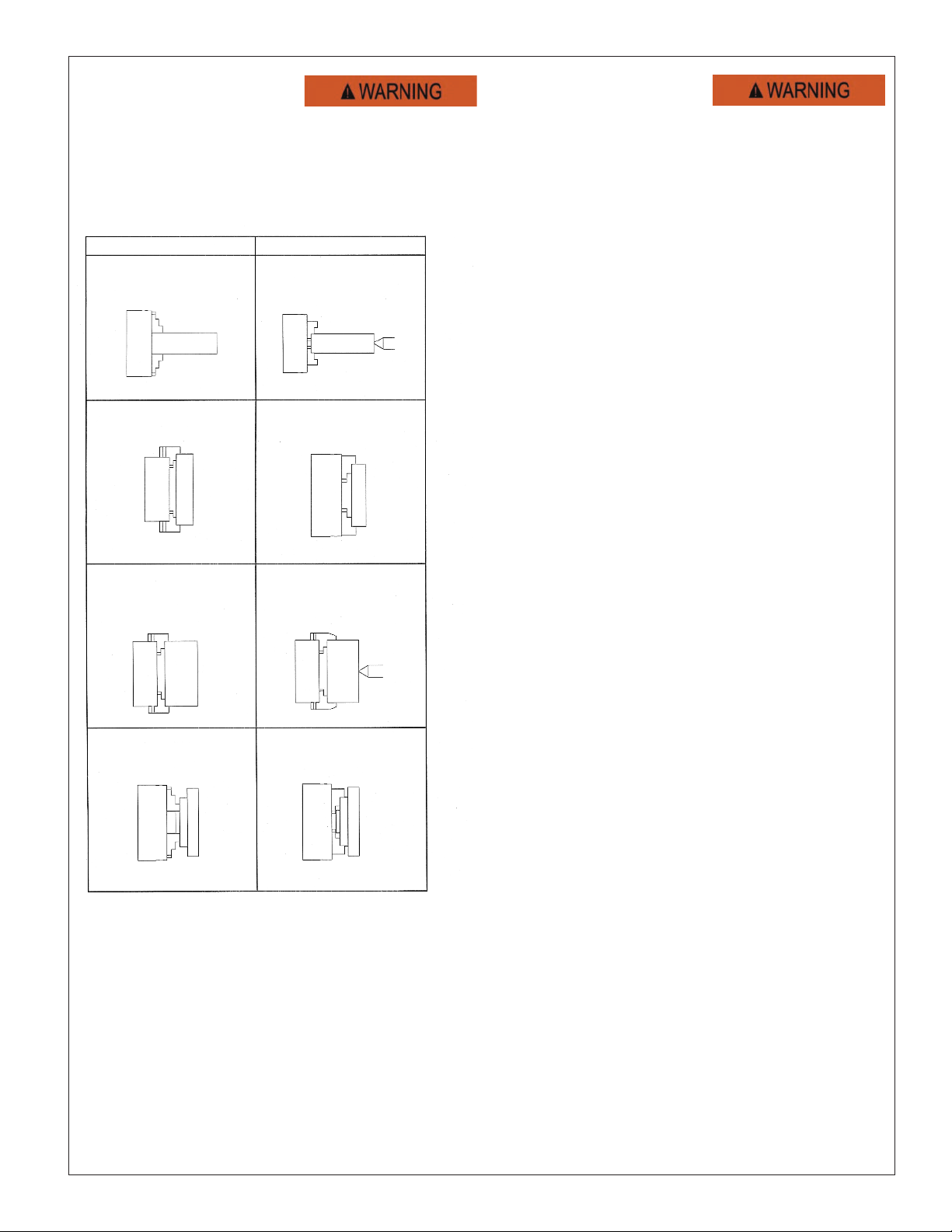

Figure 1 Figure 2 Figure 3

2

7. Op rating

In order to ensure safe clamping of the work

piece to withstand the machining forces occurring

and prevent injury, the correct loading practices

below should be adhered to:

Wrong Right

Work piece projected

length too great relative

to chuck size.

Support Workpiece

between centers.

Chucking Diameter too

great.

Use a larger chuck.

Chucking diameter too

small.

Chuck using greatest

possible chucking

diameter.

Workpiece too heavy

and chucking step too

short.

Support between

centers and extend

chucking step.

The illustrated examples do not cover all the

possible dangerous situations.

It is the responsibility of the user to recognize

possible sources of danger and to adopt the

necessary measures. Despite all precautionary

measures, an element of risk

can not be excluded.

8. Maint nanc

The reliability of the clamping equipment can only be

ensured if the maintenance guidelines below are strictly

observed. Failure to observe these instructions will result in

loss of grip and could cause an accident.

All chucks should be checked regularly for wear, cracks

and accident damage, the following cause breakages

and should be avoided:

- Do not extend the crosspiece of the chuck key

- Do not use a power wrench to open & close

the chuck

- Do not use a badly fitting operating key

- Do not use the pinion socket to remove the chuck

from the spindle.

- Do not leave the key in the chuck when the lathe is

started.

- Do not start the lathe until all is clear. Collision

between chuck and lathe will almost certainly

damage both.

- Do not use the chuck where as the work piece

diameter is too large resulting in the jaws projecting

beyond the chuck body. Use the jaws in

the correct position. Do not attempt to insert chuck

jaws into the wrong jaw way. The jaws and jaw ways

are numbered correspondingly.

- Do not tamper with the chuck. If inaccuracy is

found, check the spindle nose or adaptor plate

for true running and make sure there is no dirt of

foreign matter between the mounting faces.

- If in doubt, do not use the chuck, contact Pratt

Burnerd

Lubricate the chuck at regular intervals using

Pratt Burnerd chuck lubricant PB160Z, Refer to

material data sheet for all information referring to

PB160Z. Do not use any other brand of lubricant.

To obtain maximum benefit, the chuck parts

should be cleaned thoroughly with a suitable

cleaning fluid before applying the lubricant with a

clean brush.

If spares are fitted to the chuck, ensure these are

supplied by Pratt Burnerd, if screws are loosened

or replaced, defective fastening or replacement

may lead to a damage of the machine or injury to

the operator. The torque table below should be

used when retightening any fasteners Ensure that the

chuck has been tested before reusing.

Use the Pratt Burnerd Radio Frequency Gripmeter to

check the static and dynamic grip.

Pratt Burnerd International will advise on any problem

concerning maintenance.

1

3

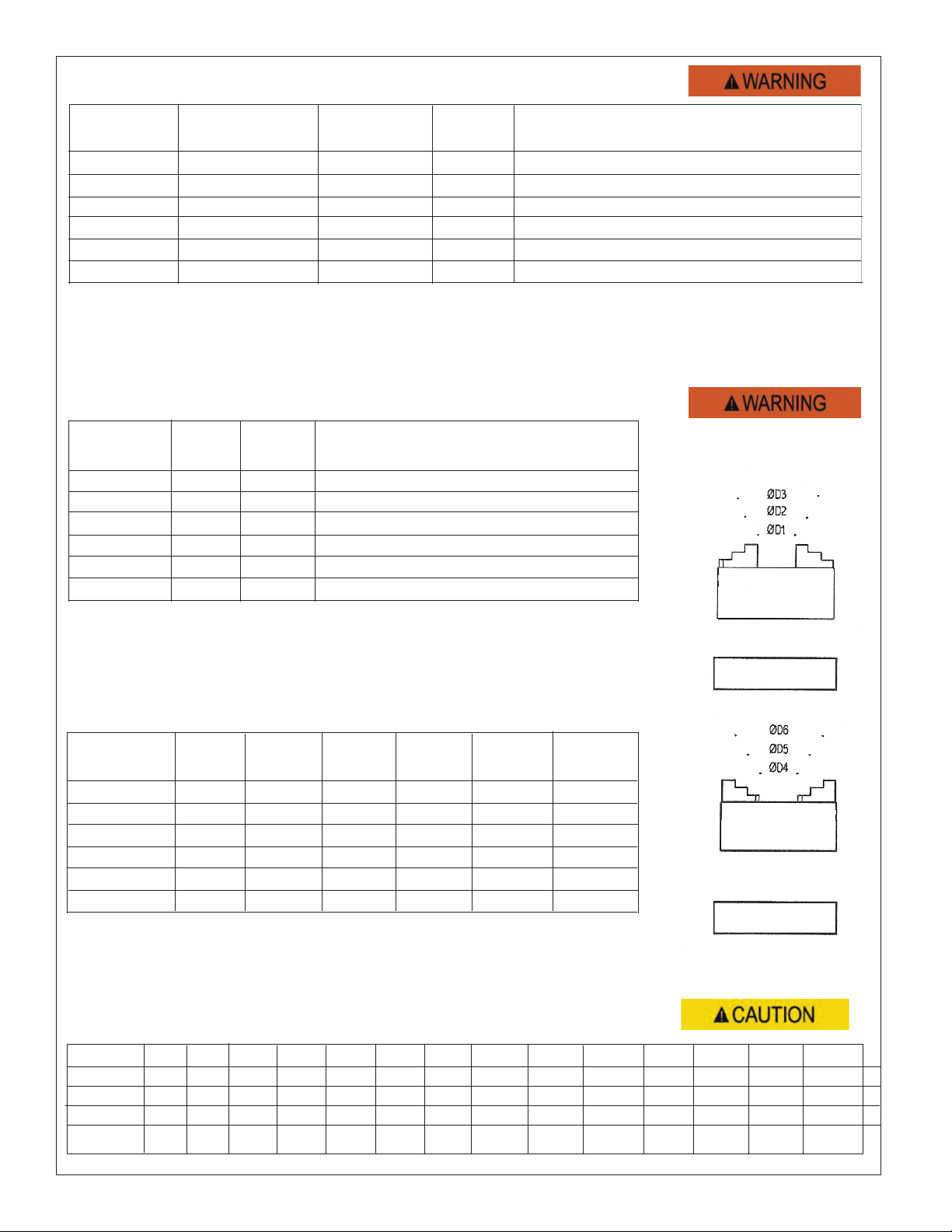

Chuck Siz Max Input Total Forc 3 Jaw Approx W ight 6 Jaw Approx W ight

in (mm) Torqu lbs/f (Nm) lbs/f (KN) Maximum 3 Jaw Kg Maximum 3 Jaw Kg

4.92" (125) 40 (52) 5,400 (24.1) 5000 6 3600 7

6.3" (160) 55 (75) 7,500 (33.4) 4900 12 3500 12

7.87" (200) 85 (115) 10,500 (46.8) 4200 21 3000 22

9.89" (250) 115 (156) 12,500 (55.9) 3300 32 2400 35

12.4" (315) 140 (203) 15,000 (66.9) 2300 51 2000 53

15.74" (400) 140 (203) 16,500 (73.5) 2000 66 1500 93

9 T chnical Information

10. Clamping Rang s 1 Pi c Jaws

Chuck siz D1 D2 D3 D4 D5 D6

(mm)

125 1.5-32 28-78 70-120 _ 38-84 78-124

160 1.5-56 42-98 84-152 _ 48-106 90-160

200 2-76 56-126 115-186 _ 54-128 114-200

250 3-114 60-168 148-250 _ 64-162 115-250

315 6-120 70-184 184-298 _ 76-190 190-304

400 10-187 90-268 223-400 _ 92-270 224-406

Chuck siz D1 D2 D3 D4 D5 D6

(mm)

125 1.5-48 32-80 72-118 5-51 48-94 90-136

160 1.5-62 42-102 98-158 10-70 48-108 108-168

200 2.5-68 50-116 106-172 16-82 64-130 122-188

250 4-106 66-164 124-226 16-120 84-186 146-248

315 6-126 70-190 146-266 18-138 98-218 178-298

400 8-168 110-270 178-338 20-180 106-266 176-336

2 Pi c Jaws

10. Tight ning Torqu Ranges (FT-LBS)

Scr w M2 M3 M4 M5 M6 M8 M10 M12 M14 M16 M18 M20 M24 M30

Skt Head Cap

<1.0 1-2 1-5 5-10 10-20 20-30 40-60 40-60 80-100 80-100 80-100 80-100 80-100 100-120

Skt C’sunk

_1-2 1-5 5-10 10-20 20-30 40-60 40-60 _80-100 _80-100 80-100 _

Button Head

_1-2 1-5 5-10 10-20 20-30 40-60 40-60 _

_____

Skt Set Shol. - - - 5-10 10-20 20-30 40-60 40-60

_

80-100 _80-100 80-100

_

Inside Jaws

Outside Jaws

4

PBA PBI A B C F G H I J K L

Chuck Chuck Chuck Size Hard To Base Pinion Scroll Chuck Adjusting Hardened Pinion Chuck Locking Soft To

Model No. Model No. Style Jaw Set Jaw Set Gear Gear Mounting Screw Pin Pin Wrench Screw Jaws Each

Bolts Size

0515400 9219-01351 5" 3 Jaw 8210-13602 O.D. 8210-13603 I.D. 2210-13350 8210-13330 1/4-20x3.0" DGO.375UNF.750 NR 2210-13356 2210-13395 NR 8210-13606*

0516400 9219-01356 5" 6 Jaw 8260-13602 O.D. 8260-13603 I. D. 2210-13350 8210-13330 1/4-20x3.0" DGO.375UNF.750 NR 2210-13356 2210-13395 NR 8260-13606*

0625300 9219-01360 6'' 3 Jaw 8210-17608 8210-17607 2210-17350 8210-17330 1/4-20x3.0" CPO.375UNF1.00 2219-00364 2210-13356 2210-17395 NR 2210-17609

0626300 9219-01365 6'' 6 Jaw 8260-17608 8260-17607 2210-17350 8210-17330 1/4-20x3.0" CPO.375UNF1.00 2219-00364 2210-13356 2210-17395 NR 2210-17609OP

0825300 9219-01370 8'' 3 Jaw 8210-20608 8210-20607 2219-00372 8210-20330 3/8-16x3.5" CPO.375UNF1.00 2219-00364 2310-20356 2218-20208 M10x10 2210-20609

0826300 9219-01375 8'' 6 Jaw 8260-20608 8260-20607 2219-00372 8210-20330 3/8-16x3.5" CPO.375UNF1.00 2219-00364 2310-20356 2218-20208 M10x10 2210-20609OP

1025300 9219-01380 10'' 3 Jaw 8210-25608 8210-25607 2210-25350 8219-01382 7/16-14x3.25" CPO.375UNF1.00 2219-00383 2310-20356 2218-25208 M10x10 2210-25609

1026300 9219-01385 10'' 6 Jaw 8260-25608 8260-25607 2210-25350 8219-01382 7/16-14x3.25" CPO.375UNF1.00 2219-00383 2310-20356 2218-25208 M10x10 2210-25609OP

1225300 9219-01390 12'' 3 Jaw 8210-32608 8210-32607 2210-32350 8210-32330 1/2-13x3.25" CPO.375UNF1.00 2219-00383 2310-20356 2218-32208 M10x10 2210-32609

1226300 9219-01395 12'' 6 Jaw 8260-32608 8260-32607 2210-32350 8210-32330 1/2-13x3.25" CPO.375UNF1.00 2219-00383 2310-20356 2218-32208 M10x10 2210-32609OP

1525300 9219-01400 15'' 3 Jaw 8210-40608 8210-40607 8270-40350 8219-01403 5/8-11x3.75" CPO.625UNF1.00 2219-00383 2310-20356 8271-40385 M10x10 2210-38609

1526300 9219-01405 15'' 6 Jaw 8260-40608 8260-40607 8270-40350 8219-01403 5/8-11x3.75" CPO.625UNF1.00 2219-00383 2310-20356 8271-40385 M10x10 2210-28609OP

Note: 5" Chuck use Solid I.D and O.D Jaws

*5" Chuck use soft solid jaws and are sold in sets

When Ordering spares please have the Chuck Model number available located on the Chuck face.

Contact Pratt Burnerd America, 3977 Emerald Dr., Kalamazoo, MI 49001

Phone 800-253-0820, Fax No. 269-384-3201 Web Page www.prattburnerd.com e-mail info@prattburnerd. com

5

Fig 2

14. Th S trit F atur

Pratt Burnerd power chucks are manufactured to the highest tolerances in accordance with all

accepted international standards specifications. Indeed, all sizes of Pratt Burnerd power chucks will

repeat to within 0.025mm however the absolute accuracy with which a chuck can hold and rotate a

component depends in part on the interface between the chuck and spindle nose.

The Pratt Burnerd Setrite feature has been designed to compensate for any inaccuracy which may be

introduced in mounting the chuck and spindle nose adaptor.

At the rear of the chuck body periphery there are three small cap screws (six on chucks of Ø380mm

and above) which control float between the chuck body components or between the chuck and

spindle nose adaptor.

The Setrite feature is simple to use, for direct mounting chucks, the chuck should be offered up to the

spindle nose in accordance with the instructions on page 2, ensuring that all mating surfaces are

thoroughly cleaned. The through mounting bolts should be made hand tight. Check the run out on the

chuck periphery using a suitably position dial indicator. Adjustment of the Setrite screws will bring the

chuck true on the spindle nose. The through mounting bolts should then be fully tightened.

For chucks with separate adaptors, first mount the adaptor to the spindle nose observing all the usual

precautions detailed in the mounting section of this manual. The mounting bolts should be fully

tightened. Offer the chuck up to the adaptor, insert the through mounting bolts and tighten them by

hand. Adjust the Setrite screws to obtain optimum accuracy and fully tighten the mounting bolts as before.

Once set, the Setrite screws will require no further adjustment unless the chuck is removed from the

spindle, when the above procedure should be repeated to re-true the chuck.

15. Fitting Camstuds to Camlock Mount Chucks

Chucks for direct mounting to lathes with camlock mounts are now delivered with the camlock studs

packed separately within the chuck case. This reduces the risk of damage in transit to both chucks

and studs. The following notes are offered guidance in assembling the studs to the chuck.

Screw each camstud into the mounting holes provided until the datum line is as close as possible to

the rear face without being below the surface and the screw head cutout in the line with the locking

screw hole.

Ensure that the chuck and spindle nose tapers are clean and offer the chuck up to the spindle. When

in position, tighten each of the spindle cams in turn, ensuring the datum line on each cam is between

the arrows on the spindle nose. If any don not tighten within the limits, remove the chuck and adjust

the camlock studs as required. When all cams lock within the marked limits, remove the chuck and

insert the locking screws beside each cam lock stud. Remount the chuck.

Remember once a chuck has been adjusted to a spindle nose, inscribe a reference mark so that each

time it is removed from the machine, it may be replaced in the same position. If the chuck is mounted

on a different machine from that which it has been adjusted, the above procedure should be repeated.

6

15. Insid or Outsid Jaws

The most common misunderstanding in the chucking world is the terminology of inside and outside

jaws for self centering chucks, a point which appears to have caused confusion since chucking was

introduced and still does.

OUTSIDE jaws are designed only to grip OUTSIDE components, usually of larger diameters.

INSIDE jaws are designed to grip the INSIDE diameter of a ring of cylinder but will also grip the out

side diameter of bar material which is, by far, the most common application and complicates the

terminology.

To simplify:

16. Fitting Spar Jaws

Spare jaws are manufactured to allow for some

degree of wear which may have taken place in the

chuck, therefore are left slightly oversized on the

width X of the jaw and undersize on the width Y of

the tenon and it is possible that a minor degree of

fitting may be required to obtain the correct fit of the

jaw. When fitting scroll jaws, the width of the tenon

slot Y should be ground to size by removing metal

from one side of each tenon slot. Always

grind the corresponding side of each slot in order to

preserve the accuracy of the height of the steeped

platform faces. Although ground on the gripping

faces as accurately as possible, spare jaws will not

provide the accuracy of the original set which were

ground in the chuck. To obtain original standards of

accuracy, the gripping faces and platform steps must

be ground in the chuck. It is necessary to remove all

backlash between the jaw teeth and scroll head.

7

Pratt Burn rd Am rica.

3977 Emerald Dr. Kalamazoo, MI.

(800) 253-0820 FAX (269) 384-3201

MATERIAL SAFETY DATA SHEET

CHEMTREC (800) 424-9300 (24HR)

PRODUCT TRADE NAME: Pratt Burn rd Chuck Lubricant PRODUCT CODE: PB16OZ

EFFECTIVE DATE: JANUARY 1, 2001 PB10LB

MANUFACTURED BY: HUSK-ITT CorporationPAGE 1 OF 2

THIS MATERIAL SAFETY DATA SHEET CONTAINS ENVIRONMENTAL, HEALTH AND TOXICOLOGY INFORMATION

FOR YOUR EMPLOYEES. PLEASE MAKE SURE THIS INFORMATION IS GIVEN TO THEM. IT ALSO CONTAINS

INFORMATION TO HELP YOU MEET COMMUNITY RIGHT-TO-KNOW/EMERGENCY RESPONSE REPORTING RE-

QUIREMENTS UNDER SARA TITLE 111 AND MANY OTHER LAWS. IF YOU RESELL THIS PRODUCT, THIS MSDS

MUST BE GIVEN TO THE BUYER OR THE INFORMATION INCORPORATED IN YOUR MSDS.

DOT HAZARDOUS CLASSIFICATION: NOT REGULATED GREASE OR OIL - N.O.S.

NFPA HEALTH HAZARD: 1 FLAMMABILITY: 1 REACTIVITY: 1 PERSONAL PROTECTION: B

SECTION 01 - HAZARDOUS INGREDIENTS

IF PRESENT, IARL, NTP AND OSHA CARCINOGENS AND CHEMICALS SUBJECT TO THE REPORTING

REQUIREMENTS OF SARA TITLE 111, SECTION 313 ARE IDENTIFIED IN THIS SECTION.

CAS NUMBE TLV PEL %

(NON HAZARDOUS) COMPONENTS

PETROLEUM OILS 64741-96-4 N/E N/E 60-70

64742-62-7 N/E N/E 60-70

LITHIUM HYDROXYSTEARATE 7620-77-1 N/E N/E 5-10

MOLYBDENUM DISULFIDE 1317-33-5 N/E N/E 15-25

PROPRIETARY COMPONENTS N.J.T.S.R.N.

80100362-5009P < 1.0

SECTION 02-PHYSICAL DATA

WATER SOLUBILITY. . . . . NIL BOILING POINT, F °. . . . . . . . . . . . N/A

SP, GRAVITY. . . . . . . . . . 1.02 MELTING POINT, F°. . . . . . . . . . . . N/A

APPEARANCE & COLOR . . DARK,PASTE LIKE VOLATILE BY VOLUME, %. . . . . . . NONE

ODOR . . . . . . . . . . . . . . . NONE VAPOR PRESSURE . . . . . . . . . . . . . N/A

EVAPORATION RATE . . . . N/A VAPOR DENSITY . . . . . . . . . . . . . . N/A

SECTION 03-FIRE AND EXPLOSION HAZARDS

FLASH POINT:(ASTM D92) C.O.C. 450°F UPPER FLAMMABLE LIMIT: N/D LOWER FLAMMABLE LIMIT: N/D

EXTINGUISHING MEDIA: DRY CHEMICAL, WATER FOG, FOAM, CARBON DIOXIDE, SAND/EARTH

SPECIAL FIRE FIGHTING PROCEDURES: TREAT AS OIL FIRE: USE SELF-CONTAINED BREATHING

APPARATUS. UNUSUAL FIRE & EXPLOSIVE HAZARDS: NONE

8

MSDS - Pag 2 Pratt Burn rd Am rica PART No. PB16OZ

SECTION 04-ENVIRONMENTAL AND DISPOSAL INFORMATION

ACTION TO BE TAKEN FOR SPILL/LEAKS: Stop flow, scrape, wipe, mop up, or absorb with

diatomaceous earth or other inert material. Store in appropriate container for disposal.

DISPOSAL METHOD: Disposal should be in compliance with federal, state, and local laws.

SECTION 05-HEALTH HAZARD DATA

CARCINOGENS: No carcinogens present

ROUTE OF ENTRY: Ingestion

EFFECTS OF OVEREXPOSURE: May cause irritation to eyes and skin on sensitive individuals.

EMERGENCY FIRST AID PROCEDURES:

EYES: Flush with water for at least 15 minutes.

SKIN: Wash with soap and water. See physician if irritation persists.

INHALATION: Remove to fresh air. See physician if irritation persists.

ORAL: Call a physician. Do not induce vomiting. Keep warm.

ADDITIONAL: Prolonged or repeated contact may produce mild skin irritation and inflammation.

Personnel with pre-existing skin disorder should avoid contact.

SECTION 06-REACTIVITY DATA

STABILITY: Stable

INCOMPATIBILITY: Strong oxidizing agents, welding.

POLYMERIZATION: Will not occur

THERMAL DECOMPOSITION: Carbon Monoxide, Carbon Dioxide, Metallic and Sulfur Compounds

CONDITIONS TO AVOID: Do not heat above flash point.

SECTION 07-SPECIAL PROTECTION INFORMATION

RESPIRATORY PROTECTION: Normally not needed.

GLOVES PROTECTION: Neoprene or nitrile rubber gloves recommended.

EYE PROTECTION: Approved safety glasses or goggles

OTHER PROTECTION: Chemically resistant boots and apron recommended.

WORK/HYGIENIC PRACTICES: Use standard methods

SECTION 08-SPECIAL PRECAUTIONS AND ADDITIONAL INFORMATION

Avoid storage near open flame or other sources of ignition. Spills may cause slippery floors. Proper

footwear required. Remove contaminated clothing and launder before reuse. Wash hands with soap and water

before eating, drinking or smoking. Discard contaminated leather gloves and shoes.

The above information is based on the data of which we are aware and believed to be correct as of the date

hereof. Since the information contained herein may be applied under conditions beyond our control and with

which we may be unfamiliar and since data made available subsequent to the date hereof may suggest

modification of the information, we do not assume any responsibility for the results of its use. This information is

furnished upon condition that the person receiving it shall make his/her own determination of the suitability of the

material for his/her particular purpose.

May be used to comply with OSHA'S Hazard Communication Standard 29 CFR 1910.1200. Standard must be consulted for specific requirements.

N/D - N t Determined N/A - N t applicable < - Less Than > - Greater Than

MSDS214.DOC

9

Table of contents

Other pba Bathroom Aid manuals

Popular Bathroom Aid manuals by other brands

Coram Showers

Coram Showers GB5 quick start guide

Sunrise Medical

Sunrise Medical Coopers 10211C manual

Invacare

Invacare Aquatec Sorrento user manual

NRS Healthcare

NRS Healthcare P05218 User instructions

Direct Healthcare Group

Direct Healthcare Group Linido LI2603.3 Series manual

Dietz

Dietz relaxon star SmatrCare operating instructions