RS Technologies Division of PCB Load & Torque, Inc. Toll-Free in USA 888-684-2894 716-684-0001 www.pcbloadtorque.com

HAND TORQUE-ANGLE WRENCH OPERATION MANUAL

4

2.0 SAFETY INFORMATION

Applied loads must be limited to 100% of the rated capacity.

Application of loads exceeding rated capacity can lead to

damage of the hand torque wrench and potential injury to the

operator. Therefore, always use care in applying torque to

fasteners being audited or tightened failure. Operators should

always observe standard shop safety requirements, such as

wearing steel-toed shoes, safety glasses, etc.

3.0 MECHANICAL INSTALLATION

Mechanical installation consists of attaching the proper sized

socket or drive fitting to the hand torque wrench. This socket

or drive will be lined up with the fastener being tightened.

Typical applications will be for auditing the residual torque in

a previously assembled fastener, or for final tightening of a

critical fastener.

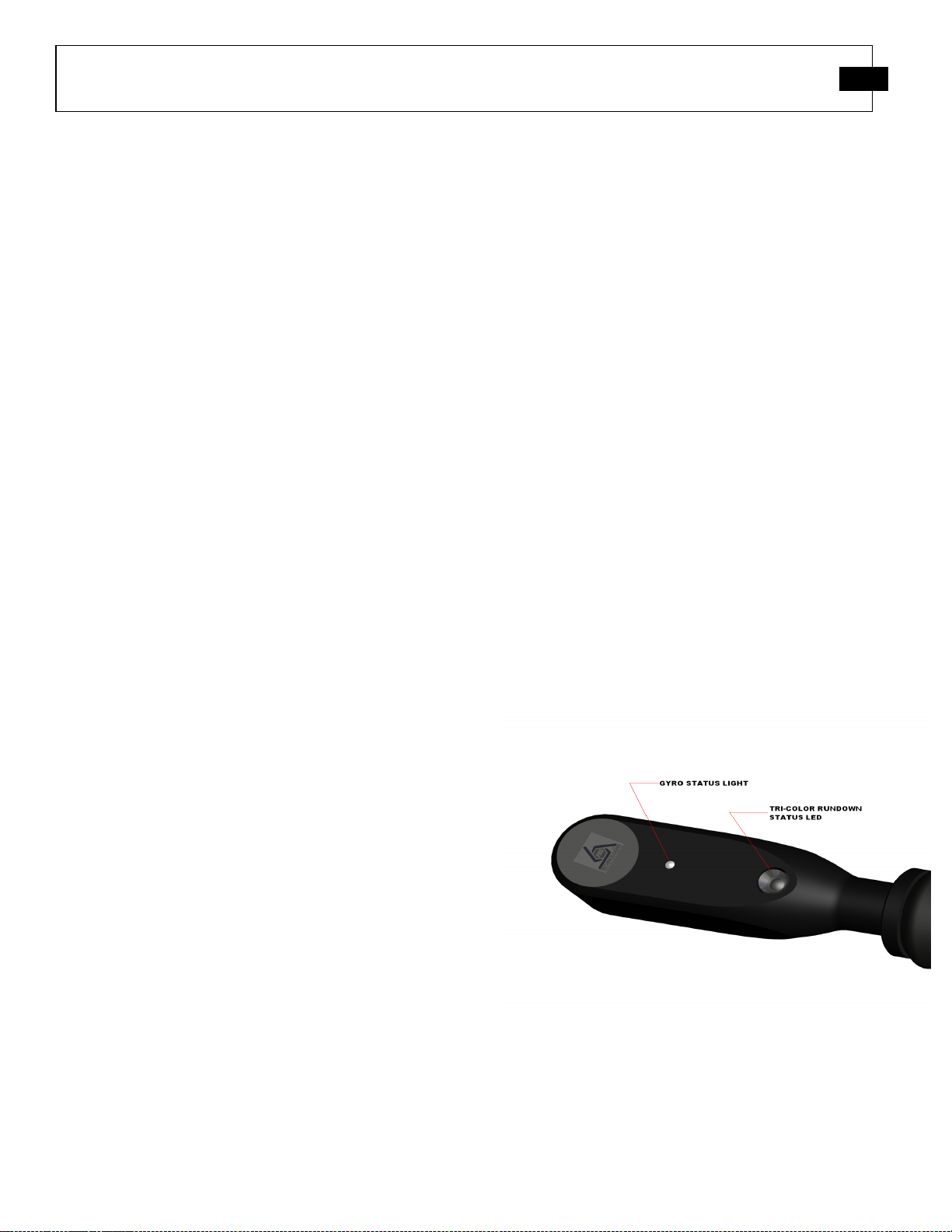

4.0 ELECTRICAL INSTALLATION

The hand torque wrench is connected to a data collector or

signal conditioner via the 10-pin PT receptacle located on the

end of the handle. Cable assemblies for RS Technologies and

other instruments are available through RS Technologies

Division of PCB Load & Torque, Inc.

Connect one end of the cable to the wrench connector and the

other end to the data collector signal conditioner. Make sure to

completely tighten the cable connector to the wrench.

5.0 POLARITY

Clockwise torque on hand torque wrenches produces a

positive-going signal output. Counterclockwise torque

produces a negative-going signal output. Most data collectors

provide a CW/CCW adjustment to ensure accurate readings.

6.0 SHUNT CALIBRATION

Shunt calibration is the known, electrical unbalancing of a

strain gage bridge by means of a fixed resistor that is placed,

or “shunted”, across one leg of the bridge. The Wheatstone

Bridge utilized by RS Technologies hand torque wrenches is

typically calibrated using the shunt calibration technique.

Shunt calibration is a practical method for providing field

calibration of data collectors and strain gage transducers such

as hand torque wrenches. This provides assurance of obtaining

accurate readings without having to apply known, traceable,

physical input loads to the wrench, which may be impractical

in an assembly line or out in the field.

Shunt calibration simulates the mechanical input to a

transducer by unbalancing the bridge with a fixed resistor

placed across, or in parallel with, one leg of the bridge. For

clockwise shunt calibration, or +CAL, the shunt resistor (R

CAL

)

is shunted across the +Excitation (A) and +Signal (C) leg of

the bridge. For counterclockwise shunt calibration, or –CAL,

the shunt resistor (R

CAL

) is shunted across the -Excitation (BD)

and +Signal (C) leg of the bridge. See Figure 1 for shunt

resistor locations in the Wheatstone Bridge circuit.

Shunt calibration is accepted throughout the industry as a

means of periodic calibration of a data collector and a hand

torque wrench between calibrations of known, applied,

traceable, mechanical input values. Consequently, most all

strain gage transducer manufacturers collect and supply shunt

calibration data, along with a shunt calibration resistor, as a

standard feature.

The hand torque wrench provided by RS Technologies

Division of PCB

Load & Torque Inc.

comes with a calibration

certificate. On the first page of this certificate you will find a

calibration value in engineering units that is associated with a

particular resistor. This resistor can be installed on the data

collector and used when matching up the instrument to the

wrench. Follow the instructions provided with the data

collector for complete details on shunt calibration procedures.

6.1 ANGLE CALIBRATION

If the torque-angle wrench will be used with an RS

Technologies Model 920, 960, or 962 meter with auto ID

enabled, the torque wrench parameters will be auto detected. If

not using the torque-angle wrench with auto ID enabled, or if

using a non-RS Technologies meter, manually enter the

‘Counts/Revolution’ value stated on the calibration certificate

into the transducer’s definition before calibrating to meter to

the wrench.