PCT Nemesis Reference guide

PROCEDURES MANUAL

Ver 2.2

©Copyright PCT 2017 2

©Copyright PCT 2017 3

FOREWORD

This manual has been written by PCT International Pty Ltd. to

provide detailed information for professional pest managers

accredited to install and service/maintain the NEMESIS TERMITE

MONITORING and BAITING SYSTEM. The manual and the

intellectual material contained within always remain the property of

PCT International Pty. Ltd. The manual is copyright.

If you have any queries or suggestions with respect to content,

send an e-mail to:

For further information, contact the technical manager,

(phone 07 3711 7022)

OR check out our PCT web site at http://pcti.com.au

Additional contacts:

PCT International Head Office:

Unit 5, 74 Murdoch Cct., ACACIA RIDGE Queensland 4110

PO Box 486

ARCHERFIELD

QLD. 4108

AUSTRALIA

Phone: (07) 3711 7022 International +61 7 3711 7022

Fax: (07) 3711 7055 International +61 7 3711 7055

Email: [email protected]

PCT warrants that this product conforms to its chemical description and is reasonably fit for

the purposes stated on the label when used in accordance with Directions for Use under

normal conditions of use. No warranty of merchantability or fitness for a particular purpose,

express or implied, extends to the use of the product contrary to label instructions or under

off-label permits not endorsed by PCT, or under abnormal conditions.

APVMA Approval №58922/20X100G/0105

©Copyright PCT 2017 4

©Copyright PCT 2017 5

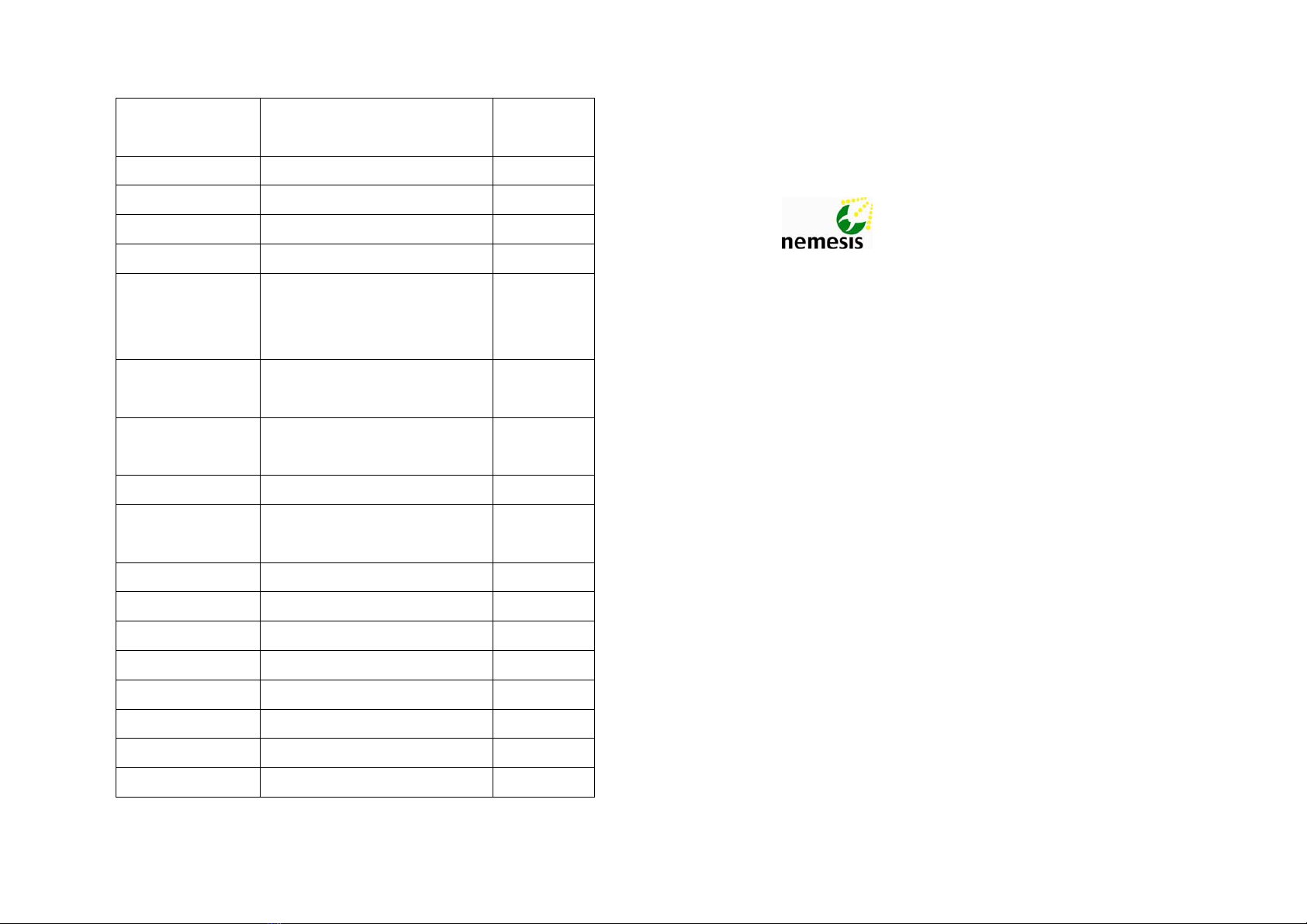

CONTENTS

Chapter Subject Page

№

1 Introduction 6

2 System Details 9

3 Health & Safety 19

4 Handling & Storage 29

5 Installation

Methods &

Procedures

31

6 Maintenance &

Servicing

43

7 Client

Responsibilities

50

8 Constraints 51

9 Accreditation

Requirements

53

10 System Photos 55

©Copyright PCT 2017 6

1. INTRODUCTION.

he TERMITE BAITING and MONITORING SYSTEM

is an integrated termite management system which relies upon

advanced, low-toxic subterranean termite baiting technology. The

active constituent of NEMESIS bait, Chlorfluazuron, belongs to a

group of control agents classified as insect growth regulators

(IGRs). Small, measured doses of the IGR in the NEMESIS Termite

Bait are presented in a highly attractive and palatable feeding

matrix to the active termites as they forage for food sources or while

they are attacking timbers. The moist bait matrix is readily

consumed by feeding termites, even in preference to alternate

foods. Over a relatively short period of time, individual members of

the termite colony (and especially the queen) undergo physical

changes that reduce their normal body function and development

by inhibiting the moulting process of their bodies. The effect on the

queen is a loss of reproductive capability, resulting in the collapse

and demise of the colony.

1.2 NEMESIS TERMITE BAIT is placed in areas where and when

active termites are encountered; it is contained within purpose-built

Stations, greatly enhancing termites’ uptake while also ensuring

product usage safety. The bait Stations can be placed either inside

structures, externally, in roof voids, in subfloor voids or underneath

buildings, and attached to other structures such as bridges,

wharves, fences, stumps or poles. The NEMESIS system, if used

according to label and Australian Standards’ instructions, has the

capacity to reduce the risk of damage caused by long term

undetected termite activity in a wide variety of structures and

situations. The NEMESIS TERMITE BAITING SYSTEM is useful for

dealing with difficult and/or environmentally sensitive sites or where

clients are wary of situations where large volumes of liquid

termiticides would otherwise need to be applied. This effective, low

toxic system uses significantly less active material than traditional

T

©Copyright PCT 2017 7

barrier treatment methods, and is far less invasive, with minimal

impact on family life or business operations during treatment.

1.3 However, the system is not a preventative barrier and it does

not provide residual protection. The Australian Standard AS 3660.2-

2000 states: “Baiting systems may be used to manage or eradicate

existing termite colonies and to monitor for future activity. They are not

prophylactic barrier systems and might not prevent future attack. They

may be used alone or in conjunction with conventional barrier systems.

Baiting can be useful in chronic re-infestation situations where other

methods have been unsuccessful. Baiting systems do not impede concealed

termite access into a building or structure.”(AS 3660.2-2000 page 23

section 6.5 Baiting Systems)

1.4 The NEMESIS TERMITE BAITING and MONITORING

SYSTEM is a proactive system which delivers an additional benefit

to professional pest managers. You can install a termite monitoring

system that is capable of intercepting termites as they forage

around a property, and, in some cases, prior to possible detectable

or observable entry into a structure. This allows the NEMESIS

termite bait to be applied for termite colony control outside a

structure. The NEMESIS TERMITE BAITING and MONITORING

SYSTEM effectively controls hidden termite nests. There is also

anecdotal evidence to suggest that termite feeding on structural

timbers is suppressed when the colony feeds on registered IGR

termite baits such as NEMESIS. This means that the risk of further

structural timber damage occurring is potentially reduced during

treatment. The system offers great flexibility for professional pest

managers as it is designed to be used either as a one-off treatment

or as part of a long term integrated management program with

provision for ongoing monitoring, in a wide range of situations.

1.5 The NEMESIS TERMITE BAITING and MONITORING

SYSTEM is intended to be used in any reasonable manner that the

professional pest manager determines to be appropriate for the

circumstances, subject to that usage being consistent with the

following:

The work follows registered label instructions.

The methodology is consistent with AS 3660, & this

NEMESIS PROCEDURES MANUAL.

©Copyright PCT 2017 8

The client has been provided with a recent written

inspection report relating to timber pests or termites for the

property, including recommendations for additional

inspections from an expert building consultant if required,

and for remedial actions to reduce the impact of conducive

site conditions. It should contain a comprehensive set of

appropriate treatment options. This will enable the client to

make an informed decision based on full disclosure of all

reasonable treatment methods along with the associated

costs, risks and limitations. It is important that the

client/professional pest manager relationship is grown in an

open and transparent environment. Any suggested

treatment program should also highlight specific key

performance indicators or landmarks and incorporate a fall-

back position or mitigation plan.

1.6 WHY USE THE NEMESIS TERMITE BAITING and

MONITORING SYSTEM?

It works-- termite baiting has been proven to work in the

field and in the laboratory.

The value of termite baiting and monitoring is recognized in

AS 3660.2-2000.

It is proactive and offers very flexible treatment options.

It is clean, safe and easy to use.

Less disruptive compared to the installation of liquid

chemical termite barriers.

Environmentally acceptable.

The product is an unscheduled pesticide and not classified

as Dangerous Goods.

The product is not hazardous according to the criteria of

Worksafe Australia.

The product is made in Australia, by Australians, for

Australian conditions.

©Copyright PCT 2017 9

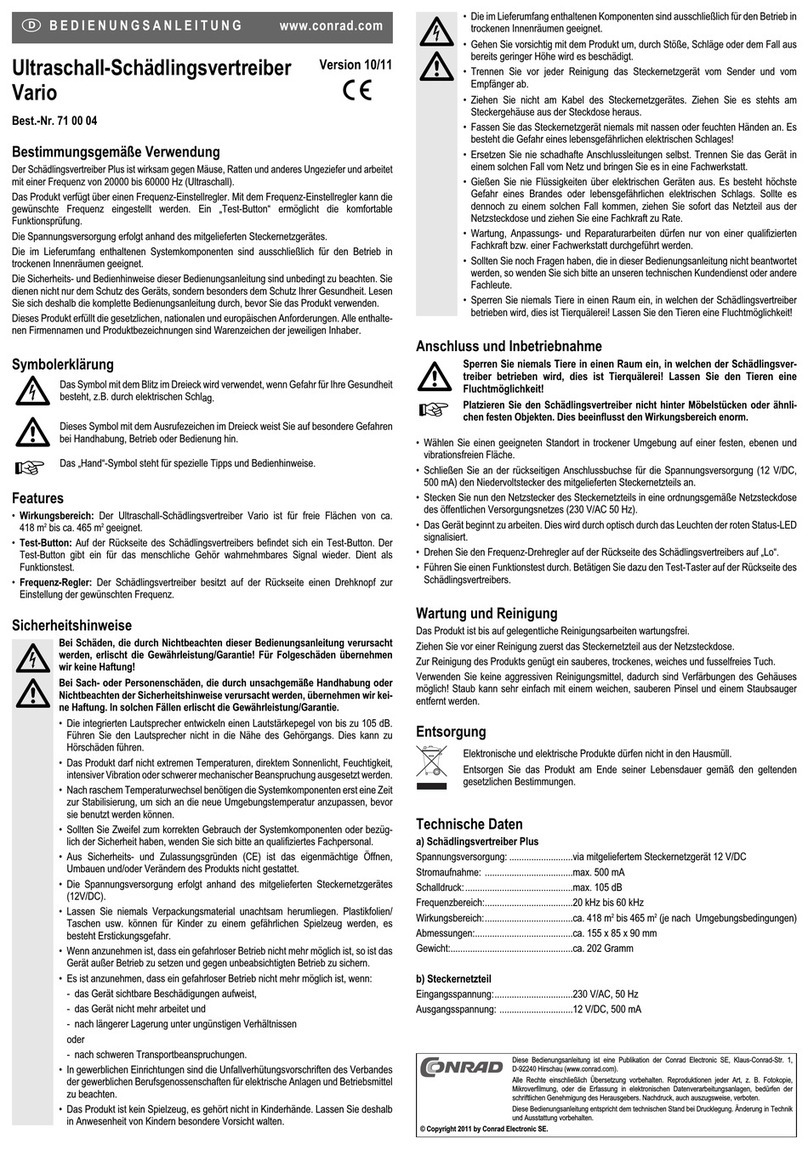

2. SYSTEM DETAILS.

The system consists of the following integrated components:

Nemesis Termite Bait

Nemesis Termite Baiting and Monitoring Stations

Nemesis Monitoring Timber Inserts

Nemesis Technical Manual

Nemesis Induction Training and Accreditation Scheme

Nemesis Support

NEMESIS TERMITE BAIT

The Nemesis Termite Bait is the key to the success of the

NEMESIS TERMITE BAITING and MONITORING SYSTEM.

2.1.1The NEMESIS TERMITE BAIT is an off-white powder (dry

formulation) intended to be mixed with water. The NEMESIS

TERMITE BAIT is packaged in individual 100gm sachets for ease of

use, product usage control, and for minimizing the risk of bait

contamination. The bait formulation has two components:

The active constituent, chlorflurazuron- an insect growth

regulator.

The carrier/bait matrix- a highly palatable cellulose based

material.

2.1.2 Only use non-chlorinated bottled water for mixing. Small

bottles are the most convenient. It is recommended that this water

is kept warm by leaving bottles in direct sunlight. Termites are

repelled by cold water. It is also recommended that the water be

added to the Nemesis bait IN the resealable bag.

2.2 Mix the bait until a uniform consistency is obtained, as per label

instructions. The amount of water used can be varied depending

upon the situation and the time of year. In high temperature

situations, more moisture is required, but in low temperature

situations, less water must be added. We strongly recommend that

between 50 to 100ml of water be used in cold weather, to ensure

that the bait mixture does not become a batter or a dough.

©Copyright PCT 2017 10

2.3 This prepared bait is then added to either inground Stations

(called NEMESIS®IGs) or above ground Stations (called

NEMESIS®AGs). Prepared bait can be placed in the station (note:

AG only), left in this bag (with an ‘X’ cut in the side of the sachet).

The bag itself can also be used as a bait station in secure

situations. If applying bait in the bag, try to orientate the moist

portion of bait closest to the termite entry point into the station (if in

an AG station). It is recommended that you prime the back of the

AG station by irrigating the access point with water laced with a

small amount of Nemesis bait.

Nemesis termite bait is only placed in areas or

stations where there are active live termites feeding. When

replacing bait in AG stations, open up the previous bag .

if eaten out, slit it further, exposing the termite fecal spotting and

place that into the station with the new bag. (Save these bags for

placing in other stations later). Note that in some situations, the bait

in the bag can be placed directly onto termite workings as a Station.

By way of example:

attached to timber, wall coverings (plasterboard). These

need to be attached with tape or stapled. Seal the

underside of the bag with No-more-gaps.

©Copyright PCT 2017 11

underneath pavers

at the base of poles, posts or piers. Wherever possible,

seal the bag and/or cover the bag with rocks or other items

with reasonable weight as a safety and security precaution.

On poles, posts or piers, it may be necessary to place a

non-bleached corrugated cardboard “bandage” around the

pole over the bait.

At floor edges inside houses it may be necessary to lift

carpet and place the bag directly to the termite feeding

zone. We recommend that corrugated cardboard or carpet

be placed over the bag and a weight be placed on top.

Some of these above procedures are useful alternate

installations for treating infestations of Schedorhinotermes

and Nasutitermes.

NEMESIS bait bag attached directly to wall above another station.

(Photo courtesy: Colin Skinner)

2.4 The NEMESIS TERMITE BAIT is a readily accepted source of

food for the foraging termite workers. It acts slowly and does not

affect the foraging termite workers whilst they transport the bait to

the termite colony. It is taken into the colony and shared with other

©Copyright PCT 2017 12

members (known as trophallaxis). The termite’s natural habits, food

preferences, energy saving and feeding behaviour are all used

against it. In order to enhance the likelihood of successful termite

bait placements, you must identify and differentiate between active

termite feeding areas and termite galleries and workings where

active termites are travelling and not feeding. NEMESIS TERMITE

BAIT MUST BE PLACED IN ACTIVE FEEDING ZONES TO

ENSURE SUCCESS.

2.5 The NEMESIS TERMITE BAIT relies upon the termite’s biology

to effect control. As termites grow and develop, they need to shed

their skin, or exoskeleton (a process called moulting), after which it

starts to reform. It is toughened up by chitin which the termite

produces. This chitinous exoskeleton is needed for protection

against shock, bumps, abrasions and the effects of desiccation

(loss of body moisture). The insect growth regulator in the bait

affects the worker termites when they shed their chitin based

exoskeletons. The IGR also affects their chitin lined digestive

system, making the absorption of nutrients difficult. (This is why

there is some anecdotal evidence indicating repressed feeding on

timber elements of the structure under attack).

NEMESIS AG Station placed at active feeding zone in a roof void.

©Copyright PCT 2017 13

2.6 Gradually, as waves of termite workers go through their cycle of

growth, development and moulting, the whole colony is affected.

The IGR affected termite workers stop feeding other termites and

they stop maintaining the colony. At first they become sluggish,

then die. When enough termites are affected or die, the termite

colony collapses.

2.7 When the termite queen is affected, the eggs do not survive.

This means that within a typical 6-16 week period after sufficient

background levels of the IGR have been established in the colony,

no replacement generations of termite nymphs survive. This

accelerates the collapse of the colony as there are no viable

replacements- the colony loses whole generations. (Note that not all

termite colonies are eliminated within 16 weeks- it may take up to 6

months).

2.8 Colony elimination normally requires that the termites feed on

between 100 - 400 grams of Nemesis Termite Bait, although

extremely large colonies could take more. Termites may consume

more bait than what is required to eliminate the colony. The size,

species and natural vigor of the termite colony influences the

amount of bait required to eradicate the colony. Older, mature

termite colonies have more constituent members, so it takes longer

to eliminate them.

The following signs are usually observable during the process of

termite baiting:

Stage1: Termite workers congregate around the bait in

large numbers. Only about one in six termites will be

soldiers.

Stage2: Termite workers become sluggish and their

appearance changes- looking at their backs, they take on a

white/chalky appearance.

Stage3: Less bait is consumed. Termite workers are fewer

in number and appear very chalky. Ratio of soldiers to

workers increases.

Stage4: No workers are observed. Only soldiers are

observed or the remnants of the harder soldier head

capsules.

Stage5: Sometimes fungal blooms are noted, and on rare

occasions a “dead prawn” smell is detected in the vicinity.

©Copyright PCT 2017 14

It is not always possible to observe all these key performance

indicating stages. When termite colonies reach Stages 3 &/or 4,

they are at the point of collapse.

2.9 By calculating and recording the amount of termite bait

consumed and by noting the physical and behavioural changes in

the termites, you can reasonably determine when the termite colony

has been eliminated.

2.10 The sharing of this information and experience with the client,

working to a plan with key performance indicators and carrying out

regular monitoring allows the professional pest manager to develop

a true partnership with the client- the client is involved in the

process. It should become easier to recommend and implement

further worthwhile non-chemical control and risk management

initiatives.

2.11 Other aspects of the termite colony’s natural biology and

behavior will also affect how quickly and when the termite colony

will collapse. In many cases they will consume more bait than what

is required to control them. In some situations, there may be more

than one colony involved. In others, e.g. Schedorhinotermes

infestations, control is likely to take months as the termites may not

moult for long periods of the year, especially in winter. In

circumstances such as this, it is recommended that a treatment

using non-repellent termiticides be carried out.

©Copyright PCT 2017 15

NEMESIS TERMITE BAITING and MONITORING

STATIONS

2.12 There are several types of Station available for use with the

NEMESIS TERMITE BAITING and MONITORING SYSTEM.

Nemesis Termite Bait can be used in other purpose designed

termite baiting and monitoring Stations or in other proprietary

systems.

2.13 These are the available Termite Baiting and Monitoring

Stations:

ABOVE GROUND STATIONS: NEMESIS AG

IN GROUND STATIONS: NEMESIS IG

STATIONS FOR PLACEMENT IN CONCRETE OR

PAVING: NEMESIS IC

ABOVE GROUND STATIONS: NEMESIS AG

2.14 PCT International Pty Ltd supplies an above-ground Station

designed to be located on and attached to active termite feeding

sites. The Station is made out of grey moulded flexible

©Copyright PCT 2017 16

polyethylene. It has built-in anchorage points, and is tamper

evident. It has a series of circular knockout points which can be

sealed with grommets (supplied). These allow a wide range of

fixing/interface orientations and flexibility for filling and inspection.

DIMENSIONS:

Length: 220mm

Depth: 50mm

Width: 115mm at widest.

IN GROUND STATIONS: NEMESIS IG

2.15 PCT International Pty Ltd supplies a plastic inground Station

which is designed to be readily stackable/transportable, taking up

minimal space in storage. The Station is made of moulded, rigid

high impact styrene, with a black body and black lid. It also

©Copyright PCT 2017 17

incorporates two timber inserts which have been designed to afford

a maximum surface area for termite attraction whilst also being

easy to prepare and install in the Stations. The mass of the timber

inserts provided with the NEMESIS TERMITE MONITORING &

BAITING SYSTEM is greater than most other comparable systems.

A palm sized multi-position tool is supplied for opening and closing

the tamper evident lid.

DIMENSIONS:

Length /depth into soil: 165.5mm

Width (tapered): 102mm at top. 70mm at bottom

Two timber inserts shaped to fit approx 35mm across and 80mm deep

Payload for bait: 70mm long with top being approx 97mm wide and

bottom being approx 82mm wide. Bait can fill gaps and grooves in

the Station.

The Station has been designed so that the timber inserts will have

significant soil contact when installed. The inserts are manufactured

from sections of Mountain Ash (Eucalyptus regnans) and Alpine Ash

(Eucalyptus delegatensis).

IG station with the timber inserts oriented for maximum soil contact.

©Copyright PCT 2017 18

IN CONCRETE OR PAVING: NEMESIS IC

2.16 For installations underneath paving or through concrete, a

stainless steel (304) cap is available which ensures an O-ring tight

waterproof seal and a flush fit with the finished ground level surface.

Non slip versions with a textured surface are recommended for high

pedestrian traffic areas.

Hole size to be drilled / core cut: 82mm

Concrete drill or core cutter to be used: 80mm

Width of cap flange on surface at finished ground level: 100mm

Force to close / tighten cap: approx. 9kgs

It is recommended that soil and swarf be removed out of the

borehole. You need to place the timber inserts into soil and have

enough room above the inserts to place bait. (You can place the

bait with a 75mm space). It is recommended that you tie two timber

inserts together with twist-tie, creating a loop handle and place this

bundle in the void.

IC Stations sealed with stainless steel caps.

©Copyright PCT 2017 19

3.HEALTH & SAFETY with

NEMESIS BAIT:

3.1 NEMESIS TERMITE BAIT is an odourless white powder

containing 1.0 g/kg Chlorflurazuron. The product is not a scheduled

poison according to the criteria of the NHMRC and is classified as

non-hazardous according to the criteria of Worksafe Australia. You

MUST always read the product label and observe all precautions

thereon. Additional information is listed on the Safety Data Sheet

(as shown below). It is also available from PCT on request (toll free

1800 630 877) or alternatively it can be downloaded as a PDF file

from our web site at http://pcti.com.au

Section 1 - Identification of the Material and Supplier

PCT Holdings Pty Ltd

5/74 Murdoch Circuit

Acacia Ridge QLD 4110

AUSTRALIA

Phone: 1800 630 877

Chemical nature: Chlorfluazuron-based termiticide.

Trade Name: Nemesis Termite Bait

APVMA Code: 58922

Product Use: An insect development inhibitor

type insecticide for use as part of a

termite interception and baiting

system as per the product label.

Creation Date: October, 2015

This version issued: October, 2015 and is valid for 5

years from this date.

Poisons Information Centre: Phone 13 1126 from

anywhere in Australia

Section 2 - Hazards Identification

Statement of Hazardous Nature

©Copyright PCT 2017 20

This product is classified as: N, Dangerous to the environment.

Not classified as hazardous according to the criteria of SWA.

Not a Dangerous Good according to Australian Dangerous Goods

(ADG) Code, IATA or IMDG/IMSBC criteria.

Risk Phrases: R52. Harmful to aquatic organisms.

Safety Phrases: S8, S61, S3/7/9, S36/37. Keep container dry.

Avoid release to the environment. Refer to special

instructions/Safety Data Sheets. Keep container tightly closed in a

cool, well ventilated place. Wear suitable protective clothing and

gloves.

SUSMP Classification: None allocated.

ADG Classification: None allocated. Not a Dangerous Good

according to Australian Dangerous Goods (ADG) Code, IATA or

IMDG/IMSBC criteria.

UN Number: None allocated

GHS Signal word: NONE. Not hazardous.

HAZARD STATEMENT:

H402: Harmful to aquatic life.

PREVENTION

P102: Keep out of reach of children.

P262: Do not get in eyes, on skin, or on clothing.

P273: Avoid release to the environment.

P281: Use personal protective equipment as required.

RESPONSE

P352: Wash with plenty of soap and water.

P301+P330+P331: IF SWALLOWED: Rinse mouth. Do NOT

induce vomiting.

P370+P378: In case of fire, use carbon dioxide, dry chemical,

foam, water fog.

STORAGE

P410: Protect from sunlight.

P402+P404: Store in a dry place. Store in a closed container.

P403+P235: Store in a well-ventilated place. Keep cool.

DISPOSAL

P501: Dispose of contents and containers as specified on the

registered label.

Emergency Overview

Physical Description & Colour: White powder.

Odour: No odour.

Major Health Hazards: no significant risk factors have been

found for this product.

©Copyright PCT 2017 21

Section 3 - Composition/Information on Ingredients

Ingredients CAS No

Conc,%

TWA (mg/m3) STEL (mg/m3)

Chlorfluazuron 71422-67-8

1g/kg

not set

not set

Other non hazardous ingredients secret to

100 not set

not set

This is a commercial product whose exact ratio of components may

vary slightly. Minor quantities of other non hazardous ingredients

are also possible.

The SWA TWA exposure value is the average airborne concentration of a particular

substance when calculated over a normal 8 hour working day for a 5 day working

week. The STEL (Short Term Exposure Limit) is an exposure value that may be

equalled (but should not be exceeded) for no longer than 15 minutes and should not

be repeated more than 4 times per day. There should be at least 60 minutes

between successive exposures at the STEL. The term "peak "is used when the TWA

limit, because of the rapid action of the substance, should never be exceeded, even

briefly.

Section 4 - First Aid Measures

General Information:

You should call The Poisons Information Centre if you feel that you

may have been poisoned, burned or irritated by this product. The

number is 13 1126 from anywhere in Australia (0800 764 766 in

New Zealand) and is available at all times. Have this SDS with you

when you call.

Inhalation: First aid is not generally required. If in doubt, contact a

Poisons Information Centre or a doctor.

Skin Contact: Gently brush away excess particles. Irritation is

unlikely. However, if irritation does occur, flush with lukewarm,

gently flowing water for 5 minutes or until chemical is removed.

Eye Contact: Quickly and gently brush particles from eyes.

Immediately flush the contaminated eye(s) with lukewarm, gently

flowing water for 5 minutes or until the product is removed, while

holding the eyelid(s) open. Obtain medical advice immediately if

irritation occurs. Take special care if exposed person is wearing

contact lenses.

©Copyright PCT 2017 22

Ingestion: If product is swallowed or gets in mouth, do NOT

induce vomiting; wash mouth with water and give some water to

drink. If symptoms develop, or if in doubt contact a Poisons

Information Centre or a doctor.

Section 5 - Fire Fighting Measures

Fire and Explosion Hazards: The major hazard in fires is

usually inhalation of heated and toxic or oxygen deficient (or both),

fire gases. There is no risk of an explosion from this product under

normal circumstances if it is involved in a fire. This product, if

scattered, may form flammable or explosive dust clouds in air.

Fire decomposition products from this product are likely to be toxic

and corrosive if inhaled. Take appropriate protective measures.

Extinguishing Media: In case of fire, use carbon dioxide, dry

chemical, foam, water fog.

Fire Fighting: If a significant quantity of this product is involved in

a fire, call the fire brigade. Do not scatter spilled material with high

pressure water jets.

Flash point: Combustible solid.

Upper Flammability Limit: No data.

Lower Flammability Limit: No data.

Autoignition temperature: No data.

Flammability Class: Combustible solid.

Section 6 - Accidental Release Measures

Accidental release: Minor spills do not normally need any

special cleanup measures. In the event of a major spill, prevent

spillage from entering drains or water courses. As a minimum, wear

overalls, goggles and gloves. Suitable materials for protective

clothing include cotton, rubber, PVC. Eye/face protective equipment

should comprise as a minimum, protective glasses and, preferably,

goggles. If there is a significant chance that dusts are likely to build

up in cleanup area, we recommend that you use a suitable dust

mask.

Stop leak if safe to do so, and contain spill. Sweep up and shovel or

collect recoverable product into labelled containers for recycling or

salvage, and dispose of promptly. Consider vacuuming if

appropriate. Recycle containers wherever possible after careful

cleaning. Refer to product label for specific instructions. After spills,

wash area preventing runoff from entering drains. If a significant

quantity of material enters drains, advise emergency services. Full

details regarding disposal of used containers, spillage and unused

©Copyright PCT 2017 23

material may be found on the label. If there is any conflict between

this SDS and the label, instructions on the label prevail. Ensure

legality of disposal by consulting regulations prior to disposal.

Thoroughly launder protective clothing before storage or re-use.

Advise laundry of nature of contamination when sending

contaminated clothing to laundry.

Section 7 - Handling and Storage

Handling: Keep exposure to this product to a minimum, and

minimise the quantities kept in work areas. Check Section 8 of this

SDS for details of personal protective measures, and make sure

that those measures are followed. The measures detailed below

under "Storage" should be followed during handling in order to

minimise risks to persons using the product in the workplace. Also,

avoid contact or contamination of product with incompatible

materials listed in Section 10.

Storage: Store in the closed original container in a dry, cool, well-

ventilated area out of direct sunlight. Make sure that the product

does not come into contact with substances listed under

"Incompatibilities" in Section 10. Check packaging - there may be

further storage instructions on the label.

Section 8 - Exposure Controls and Personal

Protection

The following Australian Standards will provide general advice

regarding safety clothing and equipment:

Respiratory equipment: AS/NZS 1715, Protective Gloves: AS 2161,

Occupational Protective Clothing: AS/NZS 4501 set 2008, Industrial

Eye Protection: AS1336 and AS/NZS 1337, Occupational

Protective Footwear: AS/NZS2210.

SWA Exposure Limits TWA (mg/m3) STEL (mg/m3)

Exposure limits have not been established by SWA for any of the

significant ingredients in this product.

The ADI for Chlorfluazuron is set at 0.005mg/kg/day. The

corresponding NOEL is set at 0.56mg/kg/day. ADI means

Acceptable Daily Intake; NOEL means No-observable-effect-level.

Data from Australian ADI List, June 2014.

No special equipment is usually needed when occasionally handling

small quantities. The following instructions are for bulk handling or

where regular exposure in an occupational setting occurs without

proper containment systems.

©Copyright PCT 2017 24

Ventilation: This product should only be used in a well ventilated

area. If natural ventilation is inadequate, use of a fan is suggested.

Eye Protection: Eye protection such as protective glasses or

goggles is recommended when this product is being used.

Skin Protection: The information at hand indicates that this

product is not harmful and that normally no special skin protection is

necessary. However, we suggest that you routinely avoid contact

with all chemical products and that you wear suitable gloves

(preferably elbow-length) when skin contact is likely.

Protective Material Types: We suggest that protective clothing

be made from the following materials: cotton, rubber, PVC.

Respirator: If there is a significant chance that dusts are likely to

build up in the area where this product is being used, we

recommend that you use a suitable dust mask.

Safety deluge showers should, if practical, be provided near to

where this product is being handled commercially.

Section 9 - Physical and Chemical Properties:

Physical Description & colour: White powder.

Odour: No odour.

Boiling Point: Not applicable.

Freezing/Melting Point: Decomposes before melting.

Volatiles: No specific data. Expected to

be low at 100°C.

Vapour Pressure: Negligible at normal ambient

temperatures.

Vapour Density: Not applicable.

Specific Gravity: No data. Bulk density about

0.25

Water Solubility: Miscible.

pH: No data.

Volatility: Negligible at normal ambient

temperatures.

Odour Threshold: No data.

Evaporation Rate: Not applicable.

Coeff Oil/water Distribution: No data

Viscosity: Not applicable.

Autoignition temp: No data.

©Copyright PCT 2017 25

Section 10 - Stability and Reactivity

Reactivity: This product is unlikely to react or decompose under

normal storage conditions. However, if you have any doubts,

contact the supplier for advice on shelf life properties.

Conditions to Avoid: Store in the closed original container in a

dry, cool, well-ventilated area out of direct sunlight.

Incompatibilities: water, strong acids, strong bases, oxidising

agents.

Fire Decomposition: Combustion forms carbon dioxide, and if

incomplete, carbon monoxide and possibly smoke. Water is also

formed. May form hydrogen chloride gas, other compounds of

chlorine. May form hydrogen fluoride gas and other compounds of

fluorine. Carbon monoxide poisoning produces headache,

weakness, nausea, dizziness, confusion, dimness of vision,

disturbance of judgment, and unconsciousness followed by coma

and death.

Polymerisation: This product will not undergo polymerisation

reactions.

Section 11 - Toxicological Information

Local Effects:

Target Organs: There is no data to hand indicating

any particular target organs.

Acute Toxicity:

•Oral: LD50 (rat) >5000 mg/kg approx.

•Inhalation: LC50 (rat) >7.0 mg/L exposure time 4h method

•Dermal: LD50 (rat) >2000 mg/kg

•Eye Irritation: (Species - rabbit) slight irritant

•Skin Irritation: (Species - rabbit) non - irritant

•Skin Sensitisation: (Species - guinea pig) non-sensitising

Potential Health Effects

Inhalation:

Short Term Exposure: Available data indicates that this product

is not harmful. However product may be mildly irritating, although

unlikely to cause anything more than mild transient discomfort.

Long Term Exposure: No data for health effects associated with

long term inhalation.

Skin Contact:

©Copyright PCT 2017 26

Short Term Exposure: Available data indicates that this product

is not harmful. It should present no hazards in normal use. In

addition product is unlikely to cause any discomfort in normal use.

Long Term Exposure: No data for health effects associated with

long term skin exposure.

Eye Contact:

Short Term Exposure: This product is believed to be mildly

irritating, to eyes, but is unlikely to cause anything more than mild

transient discomfort.

Long Term Exposure: No data for health effects associated with

long term eye exposure.

Ingestion:

Short Term Exposure: Significant oral exposure is considered to

be unlikely. However, this product may be irritating to mucous

membranes but is unlikely to cause anything more than transient

discomfort.

Long Term Exposure: No data for health effects associated with

long term ingestion.

Carcinogen Status:

SWA: No significant ingredient is classified as carcinogenic by

SWA.

NTP: No significant ingredient is classified as carcinogenic by NTP.

IARC: No significant ingredient is classified as carcinogenic by

IARC.

Classification of Hazardous Ingredients

Ingredient Risk Phrases

No ingredient mentioned in the HSIS Database is present in this

product at hazardous concentrations.

Section 12 - Ecological Information

This product is harmful to aquatic organisms.

Ecotoxicity Effects:

Acute Toxicity – Fish: LC50 for carp is >300 mg/L.

Acute Toxicity –Bees: LD50 for bees is >100 μg/L

Acute Toxicity –Birds: LD50 for Japanese Quail is >2510 mg/Kg

Further ecological information:

Ecological notes: This product is considered to be non-toxic to

bees & birds. This product is highly toxic to aquatic invertebrates.

Bait should not be placed in any area where, because of the

movement of water, it could become submersed or could be

©Copyright PCT 2017 27

washed out of a station. Particular care should be taken not to place

Nemesis in an area where it could be washed into bodies of water

containing aquatic life, such as ponds or streams.

Section 13 - Disposal Considerations

Disposal: Special help is available for the disposal of Agricultural

Chemicals. The product label will give general advice regarding

disposal of small quantities, and how to cleanse containers.

However, for help with the collection of unwanted rural chemicals,

contact ChemClear 1800 008 182 http://www.chemclear.com.au/

and for help with the disposal of empty drums, contact DrumMuster

http://www.drummuster.com.au/ where you will find contact details

for your area.

Section 14 - Transport Information

UN Number: This product is not classified as a Dangerous Good

by ADG, IATA or IMDG/IMSBC criteria. No special transport

conditions are necessary unless required by other regulations.

Section 15 - Regulatory Information

AICS: All of the significant ingredients in this formulation are

compliant with NICNAS regulations.

Section 16 - Other Information

This SDS contains only safety-related information. For other

data see product literature.

Acronyms:

ADG Code Australian Code for the Transport of

Dangerous Goods by Road and Rail

(7th edition)

AICS Australian Inventory of Chemical

Substances

SWA Safe Work Australia, formerly ASCC

and NOHSC

CAS number Chemical Abstracts Service Registry

Number

Hazchem Code Emergency action code of numbers

and letters that provide information to

emergency services especially

firefighters

IARC International Agency for Research on

Cancer

©Copyright PCT 2017 28

NOS Not otherwise specified

NTP National Toxicology Program (USA)

R-Phrase Risk Phrase

SUSMP Standard for the Uniform Scheduling of

Medicines & Poisons

UN Number United Nations Number

THIS SDS SUMMARISES OUR BEST KNOWLEDGE OF THE HEALTH AND

SAFETY HAZARD INFORMATION OF THE PRODUCT AND HOW TO SAFELY

HANDLE AND USE THE PRODUCT IN THE WORKPLACE. EACH USER MUST

REVIEW THIS SDS IN THE CONTEXT OF HOW THE PRODUCT WILL BE

HANDLED AND USED IN THE WORKPLACE.

IF CLARIFICATION OR FURTHER INFORMATION IS NEEDED TO ENSURE THAT

AN APPROPRIATE RISK ASSESSMENT CAN BE MADE, THE USER SHOULD

CONTACT THIS COMPANY SO WE CAN ATTEMPT TO OBTAIN ADDITIONAL

INFORMATION FROM OUR SUPPLIERS

OUR RESPONSIBILITY FOR PRODUCTS SOLD IS SUBJECT TO OUR

STANDARD TERMS AND CONDITIONS, A COPY OF WHICH IS SENT TO OUR

CUSTOMERS AND IS ALSO AVAILABLE ON REQUEST.

Please read all labels carefully before using product.

This SDS is prepared in accord with the SWA document “Preparation of Safety Data

Sheets for Hazardous Chemicals - Code of Practice” (December 2011)

©Copyright PCT 2017 29

4. HANDLING & STORAGE

CONSIDERATIONS:

4.1 NEMESIS TERMITE BAIT is supplied in 2kg cartons containing

20 re-sealable 100gm packs to facilitate cleanliness, measurement,

mixing and record keeping. It is a very light powder, similar to flour.

It is easily blown about by wind, so ensure you open the pack in a

calm, dry area. Place a drop sheet under the material and

equipment when mixing it indoors.

4.2 It is ESSENTIAL that both the Nemesis Termite Bait and

associated treatment components and tools are kept free from all

contaminating substances. Ensure that Nemesis Termite Bait and

other system components are kept in sealed storage units well

away from all pesticides and pesticide measuring, mixing and

application equipment. Double wrapping or sealing would be an

effective means of achieving this, or consider setting up a special

purpose vehicle or trailer.

4.3 The presence of odours from tobacco, aftershaves, deodorants,

pesticides, etc. on the Stations is highly likely to deter termites from

entering and feeding. Do not bait while wearing insecticide

contaminated clothing. Use only distilled or filtered water (non-

chlorinated) for mixing the bait. You do not need to use stirring

sticks or buckets. If you do decide to use them, make sure that they

are not contaminated with pesticides. It is highly recommended that

you mix water with the bait INSIDE the plastic bag/sachet as this

reduces the risk of contamination and is more convenient. You

should always wear disposable latex or rubber gloves while

handling and installing the Stations and timber inserts to prevent

tainting and possible termite avoidance of the Stations. Do not use

the same digging tools used to create chemical barriers for

Nemesis installations. Termites are sensitive to even the slightest

odors.

4.4 You can prepare termite bait in the original sachet before taking

it into a roof void or sub-floor. If it is not needed, you can save the

bait and re-use it on another job. You can take sachets/bags of

termite bait plus a small bottle of water in your overall pockets more

©Copyright PCT 2017 30

conveniently with the Nemesis system and make your treatment

decision at the “coalface”. Reseal any unused opened product (to

be used later) in the original ziplock pack. You can either use the

bag as a bait station or insert the folded plastic sachet into the

above-ground station. After folding it in half, cut a small ‘X’ on the

outside of the bag to allow easy termite access to the bait. It is

important to orientate the small portion of moist bait next to the

termite entry point.

4.5 NEMESIS TERMITE BAIT is easily cleaned up using just a cloth

and water. It is often best to let it dry and then remove it with a

vacuum cleaner or a stiff brush and pan. Prevent entry of spilled

matter into drains and waterways.

©Copyright PCT 2017 31

5. INSTALLATION METHODS

and PROCEDURES:

RECOMMENDED EQUIPMENT AND TOOLS:

5.1 This is a comprehensive list of items which are needed or may

be useful for NEMESIS installations and maintenance.

Clipboard and pen

Site Plan - for Station location

Torch - strong bright beam (spares recommended)

Termatrac™ Unit & Moisture Meter - for locating evidence

of possible termite activity and/or conducive conditions &

placement of Above-ground Stations (strongly

recommended)

Various hand tools - screwdrivers, pliers, hammer, etc. for

spot repairs and accessing concealed areas

Scratch Awl - for inspections and probing galleries,

mudding and shelter tubes

Gyprock saw - for accessing wall cavities

Specimen bottles (with alcohol) - to take samples of

termites for later identification

NEMESIS TERMITE BAITING and MONITORING

SYSTEM components

Latex disposable gloves - to avoid contaminating the inserts

or Stations

Plastic collar - (optional) for excess soil removal while

drilling holes for Inground installations.

Fluorescent dots - (optional) to place on foundation walls to

help locate Stations

Surveyor’s Flags - (optional) to locate In-ground Stations

Auger/Post Drill - for drilling In-ground Station holes

Auger bits - for creating In-ground Station holes as well as

cleaning out concrete core bore holes (100mm for into soil

and 75mm for clearing in-concrete bore holes)

Trenching shovel - to dig holes for Stations.

Black & White indelible markers - for marking walls etc. and

black Station lids

Stiff paint brush - to remove debris from Station lids

©Copyright PCT 2017 32

Broom - to sweep up waste materials after installation

Heavy duty hexagonal pinch bar - (recommended) for use

in stony ground for Station placement

Tape measure - (recommended) to assist with Station

location

Selley's Knead-It - for pipe repairs

Additional timber inserts - to replace old inserts

Long nose pliers - to remove inserts from IG Stations

Stainless Steel Plugs - for sealing concrete holes

Cordless drill & drill bits

Nut driver - to unlock/lock stainless steel concrete plugs

Phillips-head screws 6g x 20mm &6g x 40mm self-tapping -

for attaching Above-ground Stations

Phillips-head driver for power drill (100mm long) - for Above-

ground Stations

Selley’s ‘No More Gaps™’- for sealing Above-ground

Stations to surfaces

Stanley knife - to cut access channels

Suitable water container (20L recommended)

Clean mixing containers/buckets - for mixing bait

Scoop - for measuring out bait

Stiff spatula - for mixing bait

Syringe - for injecting liquid, diluted mixture of bait into

galleries

Professional caulking gun - to apply bait into Above-ground

Stations

Funnel - to apply bait into Above-ground Stations

Water spray bottle - for moistening bait needing re-

hydration in Stations

Cloths - for wiping up spills

Drop sheets - to prevent spillage on carpets, etc.

Dust pan and brush - for site clean-up

Spare buckets - for site clean-ups

Duct Tape - to seal access holes and assist with Above-

ground Station placement

Temperature Probe - (optional) for determining if termite

activity in trees has ceased

Drill bit 10-14mm diameter x 400mm (or longer) - for test

drilling trees

Copper Napthenate - to protect trees from fungal entry after

drilling

Sealant - to reseal drill holes in trees

Combined Garden soil pH & moisture meter –to identify

likely termite monitor positions.

©Copyright PCT 2017 33

NEW SITE INSTALLATION:

5.2 It is important to carry out a termite inspection (and prepare a

written report with a full set of recommendations) prior to agreeing

to undertake a limited or integrated termite treatment and/or

monitoring program. This is in the best interests of both you and the

property owner- the client needs to make an informed decision-

they should be offered a broad range of options. The client also

needs to understand the benefits, the likely outcomes and the

limitations of the proposed treatment. If there is a possibility of

termite damage (either hidden or visible) there must be a specific

recommendation for the client to engage the services of a building

expert to ascertain the extent of structural damage and integrity.

This needs to be expressed fully in writing.

5.3 SITE MAP: A site map indicating suspected or known areas of

termite activity and/or damage should be drawn up either prior to or

on the day of installation, with proposed Station locations marked

on it. (Be aware of possible site changes since the original

quotation). PCT provides a suitable form for this purpose─it is

available either on a CD or from the NEMESIS website. Check for

visible and anecdotal evidence of the presence and location of

power & telephone cabling, water & gas pipes, drains and sewage.

5.4 IN GROUND STATIONS: Lay the prepared NEMESIS IG

Stations on the ground around the structure at the proposed points

of installation, and review these preliminary locations according to

the Station location guidelines below. If the review necessitates any

Station placement changes or additions, make them at this time.

5.5 INGROUND STATION LOCATION/ POSITIONING: Stations

should be located close to the structure, with the optimal location

being along the roof drip line- i.e. a line extending around a building

directly underneath guttering. If the building has gutters extending

past the external walls, locating Stations slightly under the eaves

will reduce the amount of moisture that may enter the Station. Lawn

areas are not likely to promote or support termite activity and should

be avoided if possible when choosing sites for inground Stations.

The ideal Station distance from the walls of the structure is along a

©Copyright PCT 2017 34

line 600mm perpendicularly out. However, do not place them in

closer than 450mm, especially if the structure has been previously

treated with a soil termiticide. Footings could also be an obstacle to

installation closer than 450mm. Note the following:

1. There should be at least one In-ground Station for every

five perimeter lineal metres. The optimal Station loading is

one for every three perimeter lineal metres. The actual

Station to Station distance will be subject to conditions

encountered at individual sites.

2. Ensure that ALL sides of the structure are dealt with

wherever possible. E.g.,even though termites may be

attacking only the western side of the property, the colony

may be located to the east.

3. Place Stations strategically- don’t simply place Stations

strictly by formula every three metres- place them where

termites are more likely to be tracking.

4. Install Stations at or near points of known or suspected

termite entry into the structure. These Stations are intended

to intercept termites actively attacking the structure and are

the most important inground Station installations you will

make. Therefore choose the number and location of these

Stations carefully. The closer you can place the Stations to

the point of any termite entry into the structure, the higher

the probability that you will intercept the colony and

successfully treat it.

5. If an area of accessible ground is not located within 3m

of a point of known termite entry (due to a surface such as

a concrete slab or paved area), it will be necessary to

create access through that surface, close to the point of

known entry, and establish a Station there. Placing in-

ground Stations with or without the lid directly underneath

pavers is a useful technique.

6. Install Stations at no more than 1.5m from points of

known, suspected or likely termite foraging. Such places

may include areas with concentrations of cellulose-

containing debris, such as mulch or wood scraps in contact

with the ground, areas of moderate soil moisture, shaded

areas, areas containing plant root systems, drain traps,

visible termite foraging tubes, stored firewood, wooden

parts of the structure in contact with the ground, retaining

walls, etc. Station placement near compost mounds is

©Copyright PCT 2017 35

recommended since termites are frequently intercepted

there.

7. Do not underestimate the potential of termites to forage

widely. Termites find the following environmental features

attractive:

1. Timber or cellulose based material with a

moisture content between 12 to 15%.

2. Soil that is aerated so that they can travel easily

and can breathe. They need oxygen as well as aerobic

nitrogen (for creating amino-acids).

3. Soil with organic loading.

4. Soil with 12 to 15% moisture content.

5. Acidic soil (approx. pH6).

Enhance the effectiveness of your stations by recreating

these environmental features. Dig holes larger than the IG

stations (using soil augers to produce tight polished holes

compresses the soil, decreasing the available air and water

and makes the soil harder to travel through. After digging a

bigger hole, remove rubbish and debris. Line the bottom of

the hole with gravel. Place the station in the hole and add

soil with a high organic load or potting mix. Wet the soil, the

timber and the station. This greatly increases the soil

“shadow” of each Inground station.

Soil hole prepared for IG Station.

©Copyright PCT 2017 36

8. Stations may also be placed in subfloor crawl spaces,

preferably close to points of termite entry. This is a

consideration for terrace housing or zero boundary line

properties.

9. Where soil is shallow, the IG station can be installed to

the depth of the termite entry ports so that they are covered

at finished ground level. Soil should be mounded up against

the station, forming the apex of the mound at the station

collar.

STATION PLACEMENT CONSIDERATIONS:

5.6 Out of sight: Wherever possible, place Stations in areas where

they are inconspicuous, to minimize tampering and accidental

damage. Although the Stations are designed to make tampering

more visible, they are not tamper-proof. One of the design features

of the NEMESIS IG Station is the provision for the use of ground

tethers, but they can still be pulled out of the ground. The best way

to reduce this risk is to install Stations out of plain view.

5.7 Inspection access: However, do not place them so they cannot

be readily found during follow-up inspections. The goal is to place

them where they do not draw attention to themselves, but can be

found when necessary. Use fluorescent dots on the wall of the

building or surveyors flags to indicate where concealed Stations are

located, and mark the Station’s position accurately on the Site Plan.

5.8 Lawn Areas: Lawn areas are undesirable for Station placement

for these reasons:

1. Stations are particularly visible.

2. Stations are susceptible to lawnmower damage.

3. Evidence suggests that termite foraging potential is lower in

lawn areas compared to elsewhere.

4. Many types of chemicals are routinely applied to lawns that

may discourage termite foraging.

5.9 Areas of pesticide application: Areas where pesticides,

particularly liquid termiticides, may have been applied to the

ground, such as within 450mm of the foundation wall, should be

avoided. Termiticides (especially bifenthrin) may be repellent and

could seriously undermine the effectiveness of NEMESIS TERMITE

BAIT in controlling termites. If a regular pest management service

©Copyright PCT 2017 37

involving exterior application of pesticides is performed at the

structure, avoid spraying the chemicals anywhere near the Stations.

If common black or brown ants are a problem in a Station,

appropriate control measures around the Station may be

necessary. This can include the use of ant baits (We recommend

InTice™ Sweet Ant Gel), or else boiling water, to discourage ant

activity around the Stations.

5.10 Excessive Moisture: Areas of excessive moisture should be

avoided. If the soil is saturated in an area for a considerable part of

the year, it is unlikely that you will intercept termites there. Termites

will avoid these areas because the soil is saturated. Bait placed in

an area of excessive moisture may become unpalatable to termites

when it becomes saturated with water and/or is affected by decay

fungi. Damp areas are attractive to termites- it is only excessively

moist areas that are not.

CREATING THE IG STATION HOLE

5.13 A power-driven earth auger can be used for drilling holes in

soil, especially in hard, compacted soil situations. However, in most

cases, this procedure is not recommended. Creating holes larger

than the station with hand implements is recommended. You can

use either a hand auger, post hole digger or trenching shovel. Take

into account the location of any concealed services, pipes or

cables. When preparing the hole for the in-ground Station, make the

hole slightly deeper than the Station, thereby creating a sump area

under the installed Station. The NEMESIS IG Station is 102mm wide

at the top. If a 100mm auger is used, a reasonably tight fit should be

achieved if that is required because of conditions on site.

Power and hand soil augers.

©Copyright PCT 2017 38

5.14 Soil displaced by the excavation process must be cleaned up

in exposed areas where Stations are installed. A circular plastic

“collar” can be laid completely around the circumference of the bit

before boring begins, so that excavated dirt will fall onto the collar

as it emerges from the hole. Care must be taken that the collar

does not become entangled in the bit as it rotates. This risk is

minimised if the collar lies flat on the ground and lies no closer than

25mm from the edge of the hole that the auger is forming.

5.15 Excess soil that is not repacked around the Station during

installation remains on the collar. This soil can be placed into a

collection bucket for disposal in another area simply by picking up

the collar. It is useful to carry a supply of clean soil for packing

around in-ground Stations where stones, rocks and rubbish are

removed and more fill is needed.

STATION PLACEMENT/ INSERTION

5.16 Place the two timber inserts into the IG Station, noting the

correct orientation for maximum soil contact (see previous

photograph showing this). It may be useful to drill small holes into

the top of the timber inserts to allow the placement of screw eyes or

cup hooks which could help with removal IF the timber inserts swell

as a result of excess moisture.

5.17 Place the Station in the prepared hole and tamp the earth at

the bottom of the hole with the Station base. Add or remove soil as

necessary to achieve the desired Station depth. The Station can be

placed at almost any depth in the ground; however, the deeper it is

placed, more care must be taken to ensure cover installation and

removal remains easy.

5.18 Press the Station into the hole until the flange makes contact

with and lies on top of finished ground level. Install the Station using

ground tethers if additional security is required. As the Station is

going into the earth, push soil down against the sides of the Station

so that extra earth is placed between the Station and the sides of

the hole. This helps ensure that contact between the earth and the

Station sides is as complete as possible.

©Copyright PCT 2017 39

5.19 Clean up the Station & secure the cover. Locking or

sealing/securing with tamper evident plastic electrical ties is

optional.

IN-CONCRETE STATION INSTALLATION

5.20 Frequently, buildings have concrete paths or paving against

external walls, which will require core drilling in order to place the

Stations in the ground underneath.

5.21 It is necessary to surround the building with Stations every

three metres or so, INCLUDING these concrete areas. The

recommended hole size in concrete is 76mm - 82mm diameter, using

a concrete coring device or drill.

5.22 We recommend that you use a contractor to drill the holes.

(see Concrete Sawing, Drilling, Grinding and Breaking in the Yellow

Pages). You should first determine where you want the Stations to

be placed, taking into account the location of any concealed

services, pipes or cables, and mark with chalk or similar where the

contractor should drill the holes.

5.23 After the concrete is cored, it will be necessary to remove

earth at the bottom of the core to form a larger and deeper bait

cavity. Earth can be removed from the hole with either a drill

mounted or hand auger.

5.24 You might consider investing in your own concrete coring

equipment. A skilled operator can set up and form a single opening

in about five minutes. A source of water is necessary to keep the bit

cool.

Using concrete coring drill for station placement.

©Copyright PCT 2017 40

5.25 After the hole is drilled and the cavity formed, the next step is

putting the timber inserts in place. Depending on how deep the

cavity is, it is possible to place two or more sets of inserts into the

cavity on top of each other. Remember to leave sufficient space to

allow for the placement of NEMESIS TERMITE BAIT on top. If the

sides of the cavity are not stable, wrap material such as unbleached

cardboard around the timber inserts before placing them into the

cavity. Again it may be worthwhile to drill small holes into the top of

the timber inserts to allow placement of screw eyes to assist with

future removal.

5.26 Access to the cavity is then secured using an expandable O-

ring stainless steel plug that provides a waterproof seal for the

cavity. Don’t forget to dispose of the concrete cores properly! It may

be desirable for the client to retain some cores to assist with

plugging the hole in the event of future Station removal.

IC Station stainless steel cap.

MARKING THE LOCATION OF STATIONS

5.27 All Station locations should be clearly marked on an accurate

site map & regularly updated. (We have a downloadable version on

our Nemesis website or on CD).

5.28 Placing a fluorescent adhesive dot on the external wall of the

structure at a point directly opposite the location of the Station is

one method of making future Station location easier. These dots

should be small and inconspicuous. They should be placed slightly

above ground level at a point opposite the Station so that if a

straight line was drawn out at right angles from the wall, the line

would go over the centre of the Station.

5.29 A surveyor’s flag can be installed adjacent to a station for easy

location in areas where vegetation, leaf litter or similar might

normally conceal it.

Table of contents

Other PCT Pest Control manuals