page 15

page 2

LIMITED WARRANTY

This warranty is extended only to original consumer purchasers of our products. This warranty gives you

specic legal rights. You may also have other legal rights, which vary from state to state or province to

province.

PDG warrants the products manufactured by it to be free from defects in materials and workmanship for

a period of one (1) year from date of purchase. The side frame and cross bars are warranted for a period

of three (3) years. If, within such warranty period, any such product shall be proven to the Manufacturer’s

satisfaction to be defective, such product shall be repaired or replaced, at PDG’s option. This warranty

does not include any labor or shipping charges incurred in replacement part installation or repair of any

such product. PDG’s sole obligation and your exclusive remedy under this warranty shall be limited to

such repair and/or replacement.

For warranty service, please contact the dealer from whom you purchased your product. In the event

you do not receive satisfactory warranty service, please write directly to PDG, provide the dealer’s name,

address and date of purchase, and indicate nature of the defect. Also provide the product name and serial

number. Do not return product to our factory without our prior consent.

Limitations and Exclusions: The foregoing warranty shall not apply to serial numbered products if the

serial number has been removed or defaced, products subjected to negligence, accident, improper

operation, maintenance or storage or commercial use or other than normal application, use or service, or

to products modied without the Manufacturer’s express written consent (including, but not limited to,

modication through the use of unauthorized parts or attachments), or to products damaged by reason

of repairs made to any component without the specic consent of PDG, or to products damaged by

circumstances beyond PDG’s control.

THE FOREGOING WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER EXPRESS WARRANTIES. IMPLIED

WARRANTIES, IF ANY, INCLUDING BUT NOT LIMITED TO THE IMPLIED WARRANTIES OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE, SHALL NOT EXTEND BEYOND THE DURATION OF THE EXPRESS

WARRANTY PROVIDED HEREIN AND THE REMEDY FOR VIOLATIONS OF ANY IMPLIED WARRANTY SHALL

BE LIMITED TO REPAIR OR REPLACEMENT OF THE DEFECTIVE PRODUCT PURSUANT TO THE TERMS

CONTAINED HEREIN. PDG SHALL NOT BE LIABLE FOR ANY CONSEQUENTIAL OR INCIDENTAL DAMAGES

WHATSOEVER. THIS WARRANTY SHALL BE EXTENDED TO COMPLY WITH STATE/PROVINCIAL LAWS AND

REQUIREMENTS.

WARNING

Do not operate this equipment without rst reading and understanding this manual. If you are unable

to understand the warnings and instructions, contact a health care professional such as a doctor or a

therapist who is familiar with this type of product before attempting to use this equipment.

Refer to this manual regularly for maximum safety and performance.

TABLE OF CONTENTS

Special Notes.............................2

Safety Summary..........................3

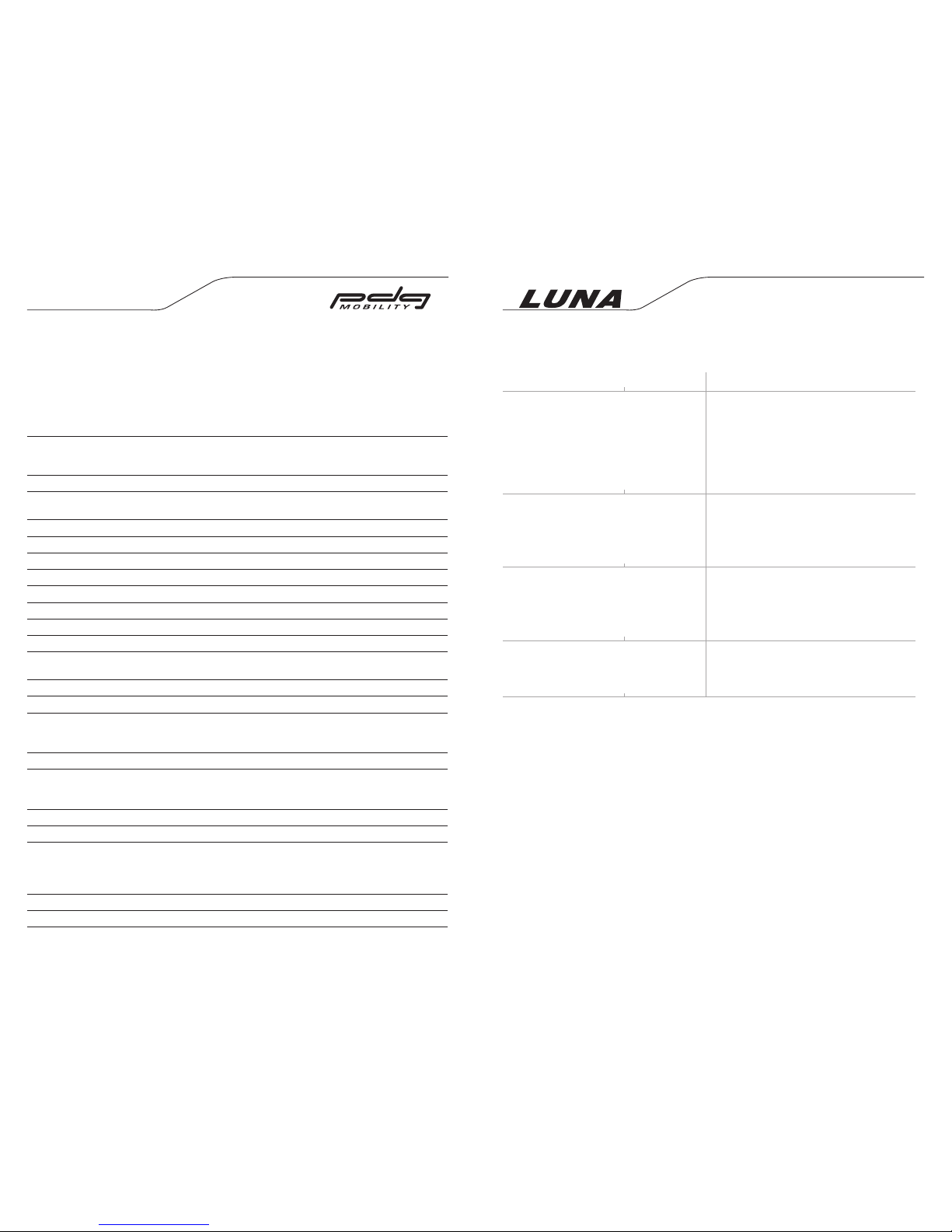

Safe Handling of Wheelchairs . . . . . . . . . . . . . 5

Wheelchair Terminology . . . . . . . . . . . . . . . . . . 7

Packaging................................7

Safety Inspection Checklist . . . . . . . . . . . . . . . 8

Troubleshooting..........................9

Maintenance ............................10

Operation & Safety . . . . . . . . . . . . . . . . . . . . . . 11

Removable Arms . . . . . . . . . . . . . . . . . . . . 11

Wheel Locks.........................11

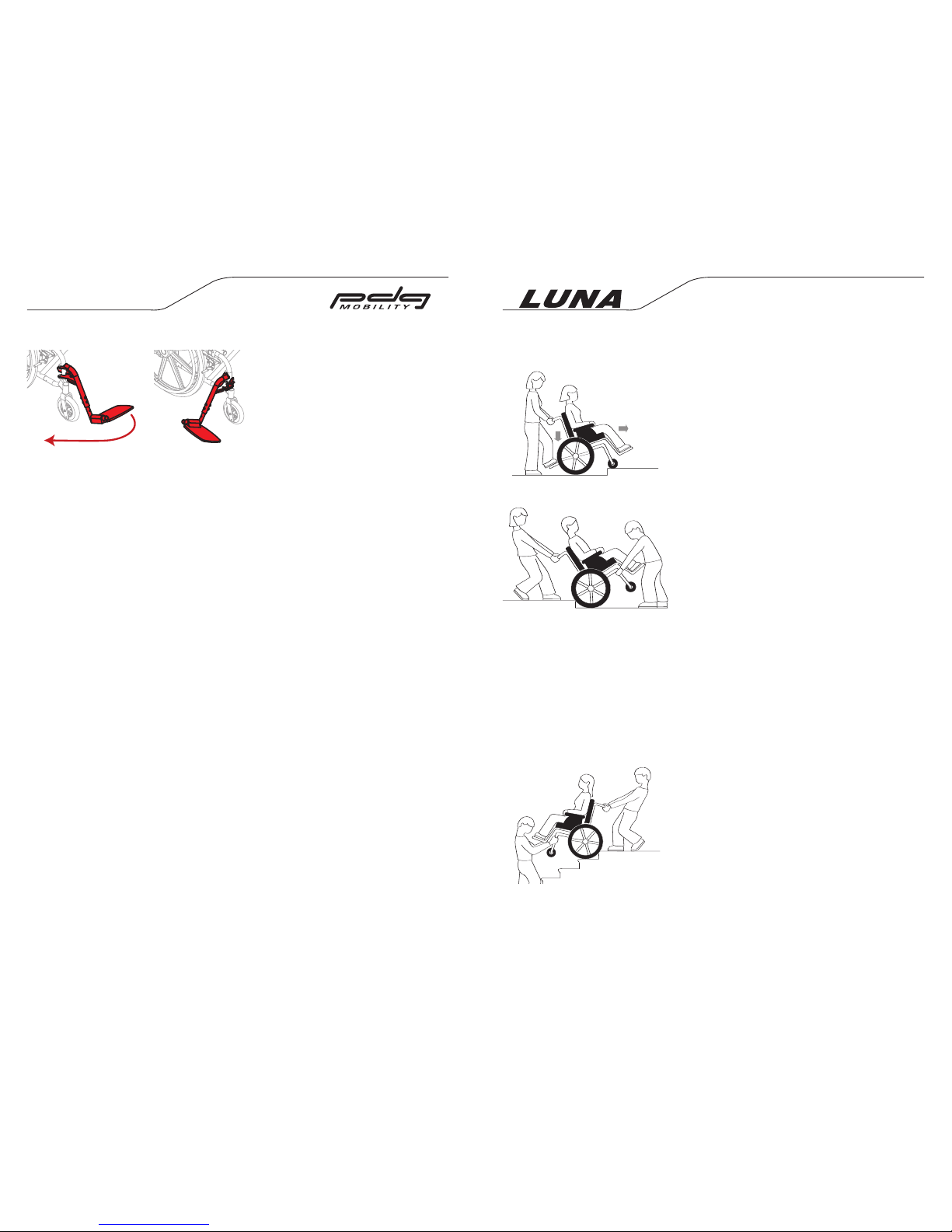

Foot Rests...........................12

Rear Axel and Anti-Tip Receiver

Subassembly Adjustment. . . . . . . . . . . . 13

Disclosures and Warranty . . . . . . . . . . . . . . . . 14

SPECIAL NOTES

WARNING/CAUTION — Notices used in this manual apply to hazards or unsafe practices which could

result in personal injury or property damage.

NOTE — THE INFORMATION CONTAINED IN THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE.

WHEELCHAIR USER — PDG mobility manufacturers and supplies a wide variety of wheelchairs and

wheel chair products to suit individual needs PDG mobility can help with product selection

process, however, the nal product selection is the responsibility of the user and his/her health care

professional.

WHEELCHAIR TIE-DOWN RESTRAINTS AND SEAT RESTRAINTS — Users of wheelchairs should be

transferred into appropriate seating in vehicles for transportation and use the restraints made available

by the auto industry. PDG does not recommend wheelchair transportation systems.

IT IS THE OBLIGATION OF THE HME DEALERS, THERAPISTS AND HEALTH CARE PROFESSIONALS TO

DETERMINE IF A SEATING RESTRAINT IS REQUIRED FOR THE SAFE OPERATION OF THIS EQUIPMENT BY

THE USER. SERIOUS INJURY CAN OCCUR IN THE EVENT OF A FALL FROM A WHEELCHAIR.