AMF BRUNS

TR600001 Installation Instructions, February 2022

AMF BRUNS

TR600001 Installation Instructions, February 2022

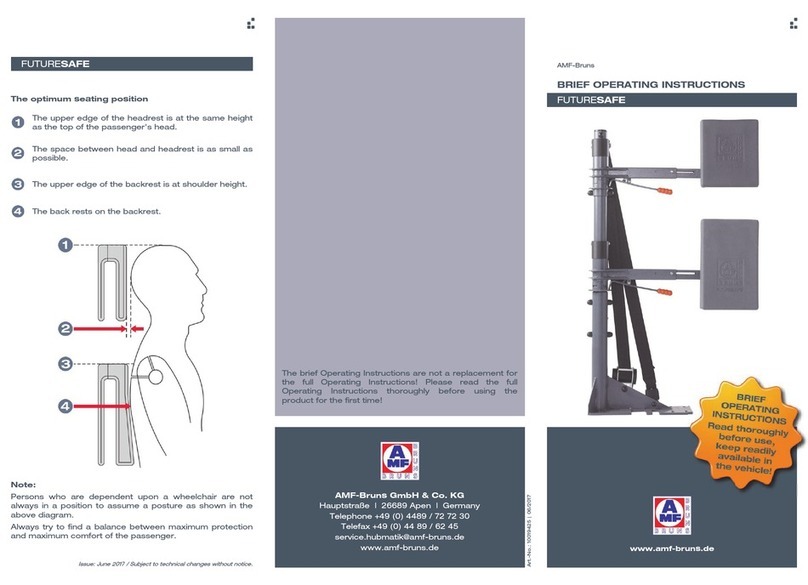

9. Shoulder belt upper anchorage or guide support should always be positioned so that:

a. Belt webbing always lies across the center of wheelchair passenger’s chest and shoulder

(See Figure 9), and

b. It extends upward and rearward of the wheelchair occupant’s shoulder level to avoid any

downward force on the spine. (See Figure 9 - Page 16)

10. Never extend the shoulder belt across the face or neck of the occupant.

11. Do not use postural support belts (belts that simply go around the occupant and mobility aid) in lieu of

an approved, FMVSS certified lap belt, designed and tested to be used in conjunction with the

securement system.

12. Always use use an AMF-Bruns’ storage pouch and AMF-Bruns’ storage box for proper storage of belts

when not in use.

13. Every vehicle should be equipped with a web cutter for use in an emergency evacuation.

14. A common wheelchair securement & occupant restraint system contains the following and are to be

used as a complete system:

(4) Retractor Tiedowns (1) Occupant Lap belt (1) Occupant Shoulder belt

(1) Warranty card (1) Installation instructions (1) User Instructions

(1) Instruction decal

Optional equipment recommended:

(1) Storage Pouch for each wheelchair position (1) Belt cutter for emergency purposes.

C. DAILY INSPECTION CHECKLIST

At a minimum, the following items should be inspected carefully on a daily basis:

1. Check the retractors by quickly pulling out the webbing to ensure proper locking.

2. Check webbing to ensure it is not nicked, cut, frayed, damaged or contaminated by dirt.

3. Check metal parts to ensure they are not worn, broken or cracked.

4. Check that all mounting hardware (such as bolts, nuts, etc.) is secure.

5. Check fl oor anchorages to ensure cleanliness and attachment.

6. Check shoulder belt anchorages for proper attachment and operation.

7. Check buckles for damage and to ensure proper operation.

8. Check male buckle tongue to ensure it is not cracked, broken or damaged.

9. Inspect the overall functionality of the restraint system.

10. Inspect all fl oor and sidewall anchorages such as tracks and plates - including bolts. Check for

excessive wear, corrosion and loose fasteners. Clean out any dirt and debris to ensure full and correct

engagement of track fi ttings.

If you have any doubt whatsoever, DO NOT USE THE SYSTEM.

Contact your dealer or AMF-Bruns of America.

D. CARE AND MAINTENANCE

1. Make sure that the restraints do not come in contact with oil, grease, dust, sand or any other

contaminants at any time. For storage, use the AMF-Bruns of America storage box or storage pouch.

2. Clean the restraints on a regular basis with mild cleaning products and/or water. Never use any

aggressive cleaners.

3. To avoid damage to the product, do not use sharp objects for cleaning, i.e. knives or scissors.

4. Frayed, contaminated and damaged webbing should be replaced immediately.

6 7

II. SPECIFIC WARNINGS AND INSTRUCTIONS

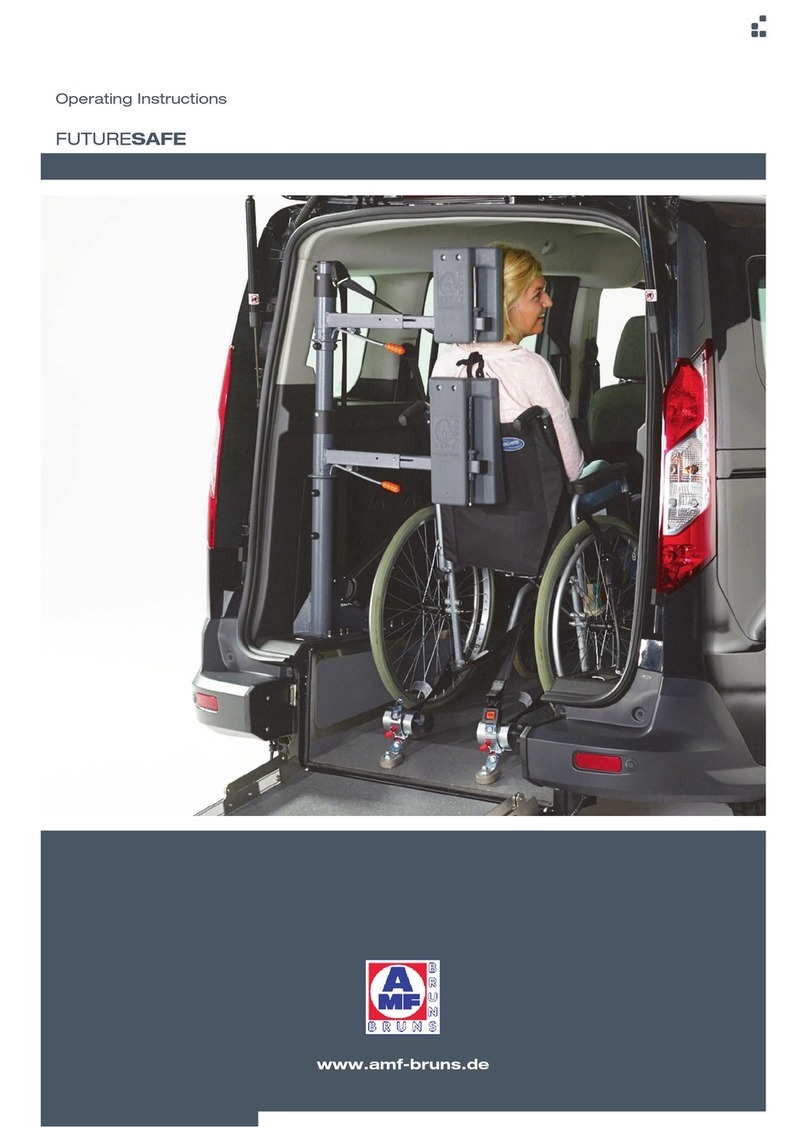

A. SECURING THE WHEELCHAIR (Figure 3 - Page 9).

1. Anchor straps shall only be secured to the wheelchair’s frame or designated attachment points. Never

attach to footrests, wheels or any detachable portion of the wheelchair. Never pass straps through

wheels of wheelchair.

2. Do not allow the straps to conform or bend around any object such as wheels or footrests. The

securement straps must have a clear, straight load path from the floor tracks or plates to where they

attach to the wheelchair frame or designated attachment points.

3. Floor anchorages such as tracks or floor pockets should be free of dirt and debris as they can interfere

with proper system operation.

4. Once you have all four straps attached, release the brakes on the wheelchair and check for movement.

Once secured, the wheelchair should not move more than two (2) inches front to back or side to side.

Re-apply the brakes.

Reapply the brakes.

6. Do not cross-connect the securement strap assemblies. This may place added stress or unequal load

forces on the wheelchair frame and may lead to potential collapse or tipping of the wheelchair.

7. Protect straps from sharp edges and corners.

8. If proper attachment and securement of a particular style of wheelchair cannot be accomplished, or if

you have any doubt whatsoever, contact your dealer or AMF-Bruns of America.

B. SECURING THE PASSENGER (Figure 9 - Page 16).

1. AMF-Bruns of America‘s restraints are designed to bear upon the bony structure of the body and

shall be worn low and snug across the front of the pelvis, with the junction between the lap and

shoulder belts located near the passenger‘s hip. The lap belt shall not be worn across the abdominal

area. Adjust occupant restraints as firmly as possible consistent with user comfort.

2. Seat belts must be snug and flat against the body and should never be twisted. They should never

be held away from the body by wheelchair components such as armrests or wheels.

3. Make sure the seat belt strap does not become twisted inside the retractors.

4. Never rely on the wheelchair’s lap belt or other occupant belts that are not tested and approved for

use as an occupant restraint.

5. This product is not designed for use with only a pelvic restraint. Always use only a lap/shoulder belt

combination.

6. Protect seat belt webbing from sharp edges and corners.

7. Use this system with only with forward-facing wheelchairs.

8. Whenever possible, any non-essential items attached to the wheelchair in front of the occupant

should be detached and secured separately during transportation.

be detached and secured separately during transportation.

5) Never use the static straps on all four points of attachment to the wheelchair frame.

They should be used ONLY as front tie-downs. The static strap is primarily a slack-

removing device and can only tension to the extent of the operator’s strength and angle

of pull. At least two of the securement strap assemblies need to have full tensioning

capability, i.e. ratchet, over-center buckles.

WARNING