Peak PCAN-cPCI Dual Channel opto-decoupled User manual

Other Peak Recording Equipment manuals

Peak

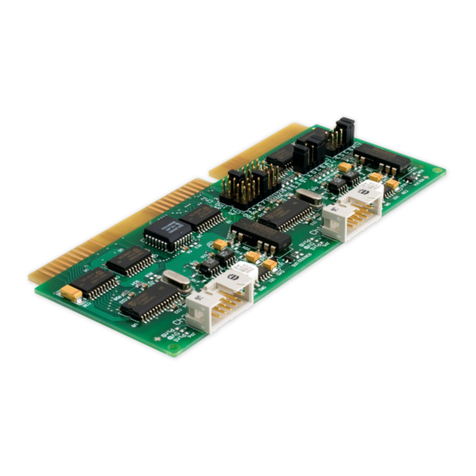

Peak PCAN-PC/104-Plus User manual

Peak

Peak USB to CAN Interface User manual

Peak

Peak PCAN-miniPCIe User manual

Peak

Peak PCAN-ISA User manual

Peak

Peak PLIN-USB User manual

Peak

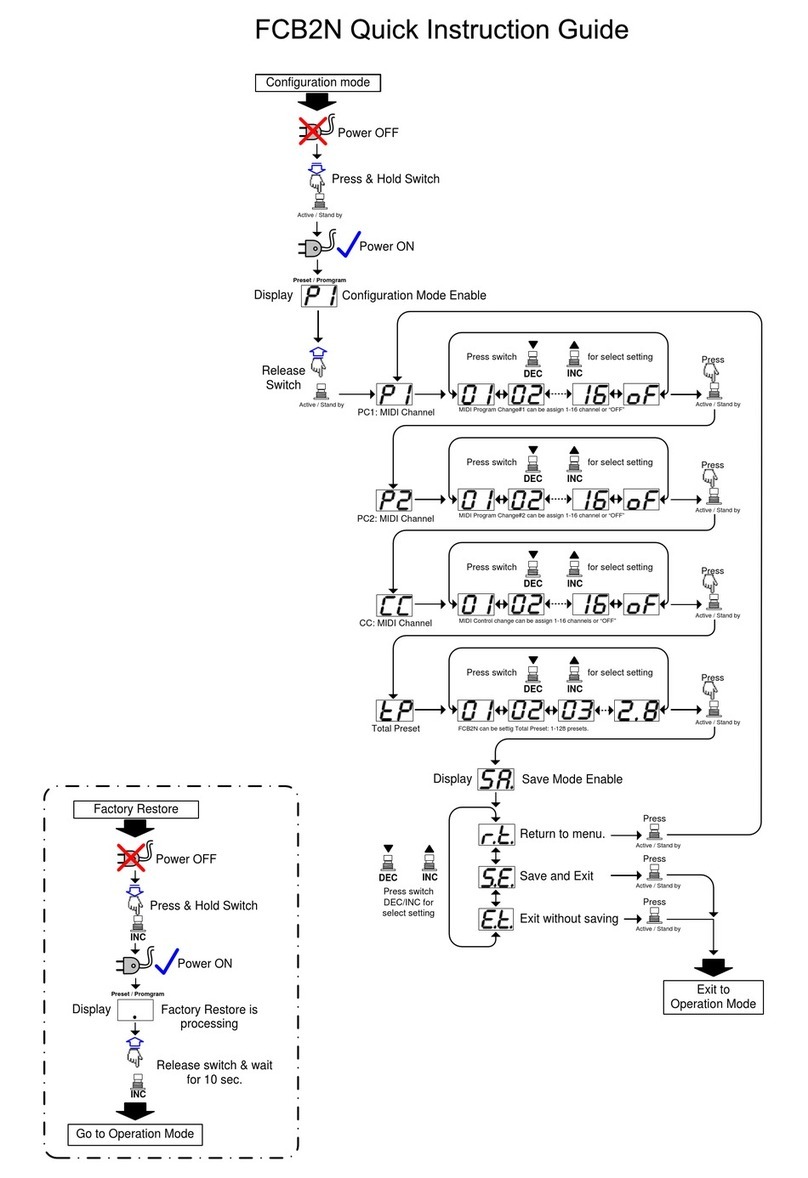

Peak FCB2N User manual

Peak

Peak IPEH-003026 User manual

Peak

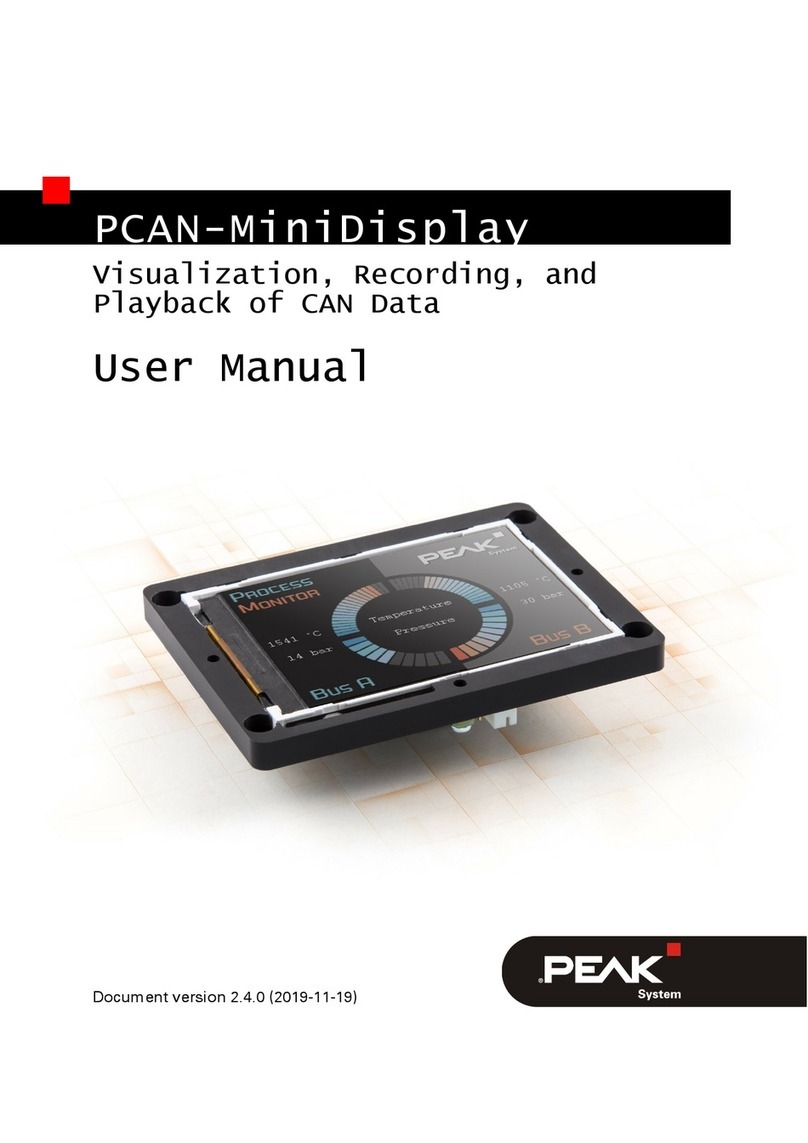

Peak PCAN-MiniDisplay User manual

Peak

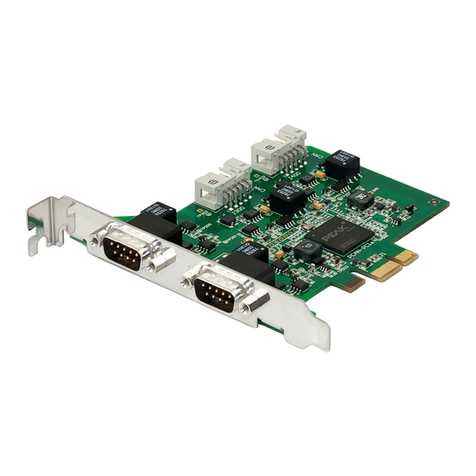

Peak PCAN-ExpressCard User manual

Peak

Peak PCAN-PC/104-Plus User manual

Peak

Peak PCAN-ISA User manual

Peak

Peak PCAN-USB FD User manual

Peak

Peak PCAN-Dongle User manual

Peak

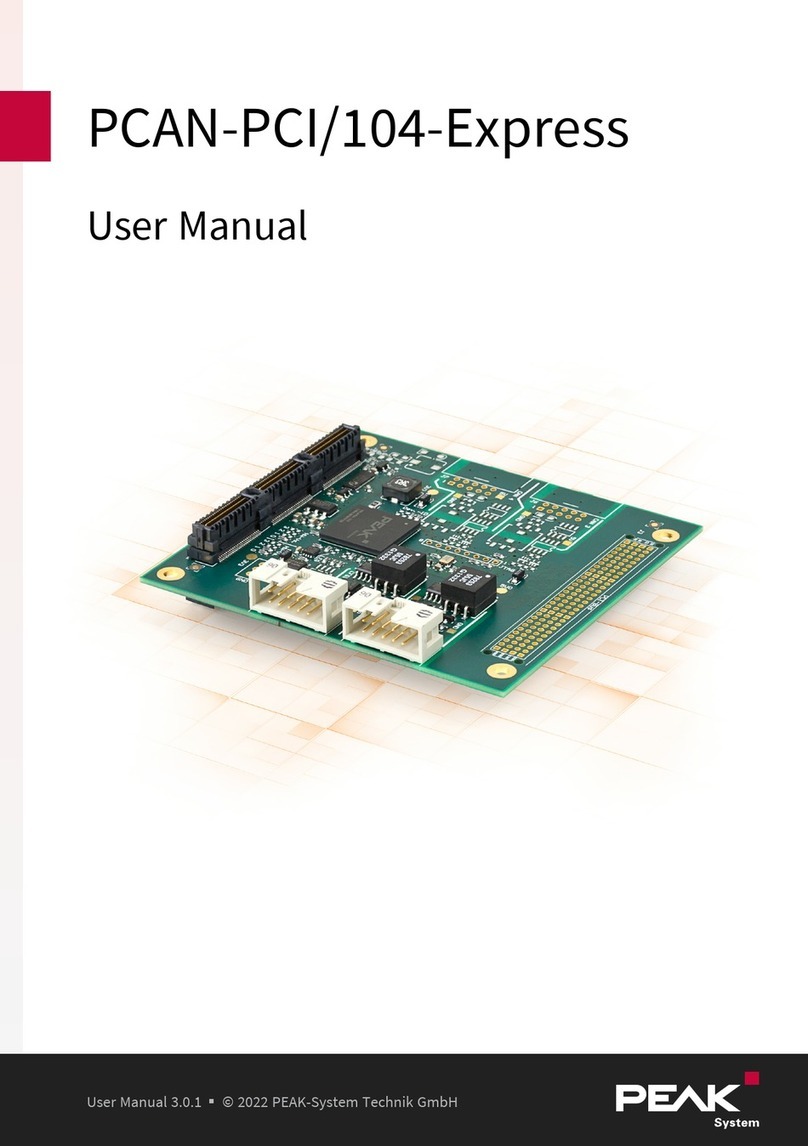

Peak PCAN-PCI/104-Express User manual

Peak

Peak FCB4N2 Mounting instructions

Peak

Peak PCAN-USB Pro User manual

Peak

Peak FCB8N User manual

Peak

Peak PCAN-USB Hub User manual

Peak

Peak PCAN-USB Pro FD User manual

Peak

Peak PCAN-cPCI User manual