Traction Dot

3-Piece Screw

Traction Plate

Velcro Strips

Allen Screw

Allen wrench

Adjustment Knob

Wing Bolt

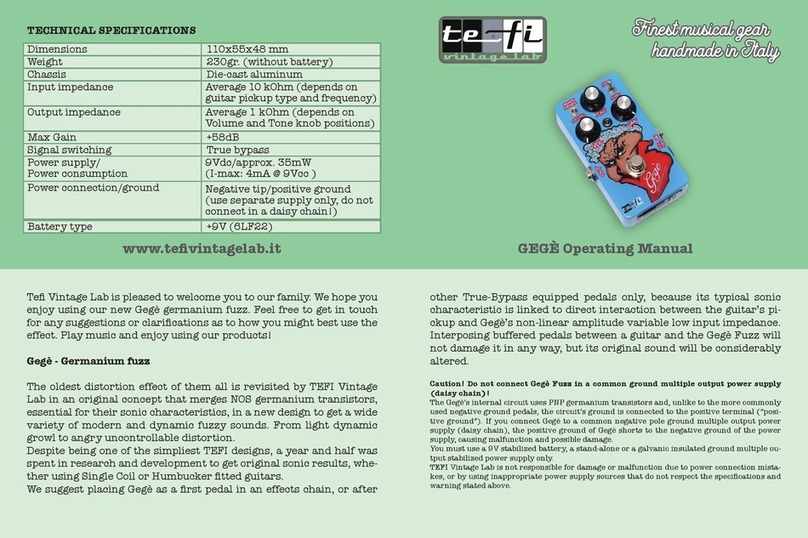

Traction Plate / Traction Dots

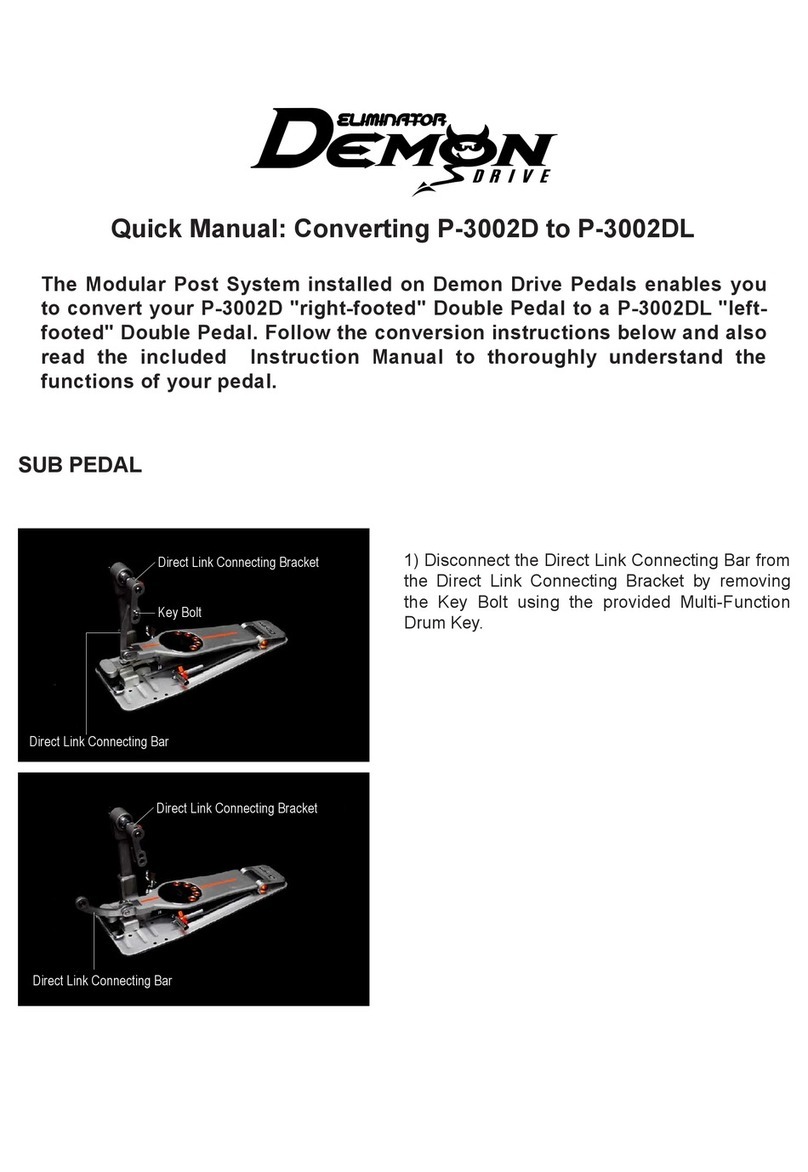

The Traction Plate adjusts to a variety of grip/slide

configurations. To change the position of the Traction Dots,

use the Multi-Function Drum Key or Allen wrench (3mm) to

remove the 3-Piece Screw beneath the footboard and

remove the Traction Plate (Fig.18). Rearrange the Traction

Dots to your preference and replace the Traction Plate.

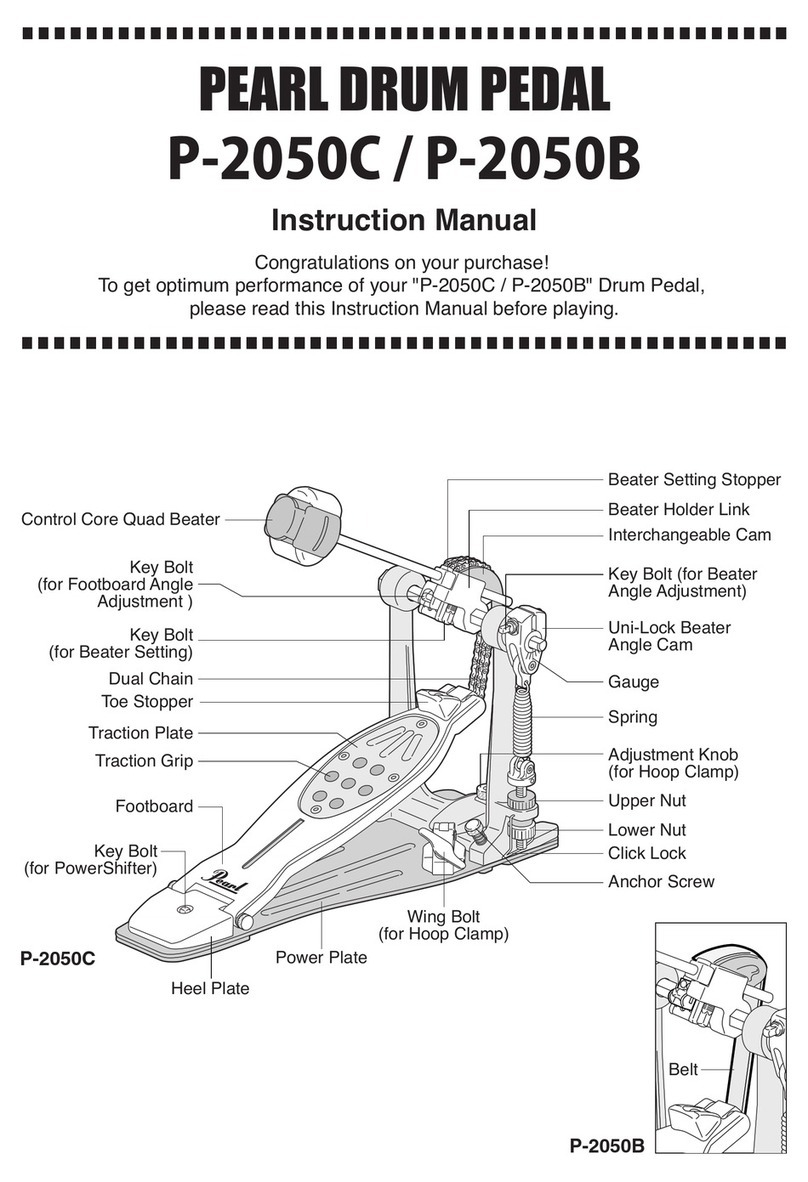

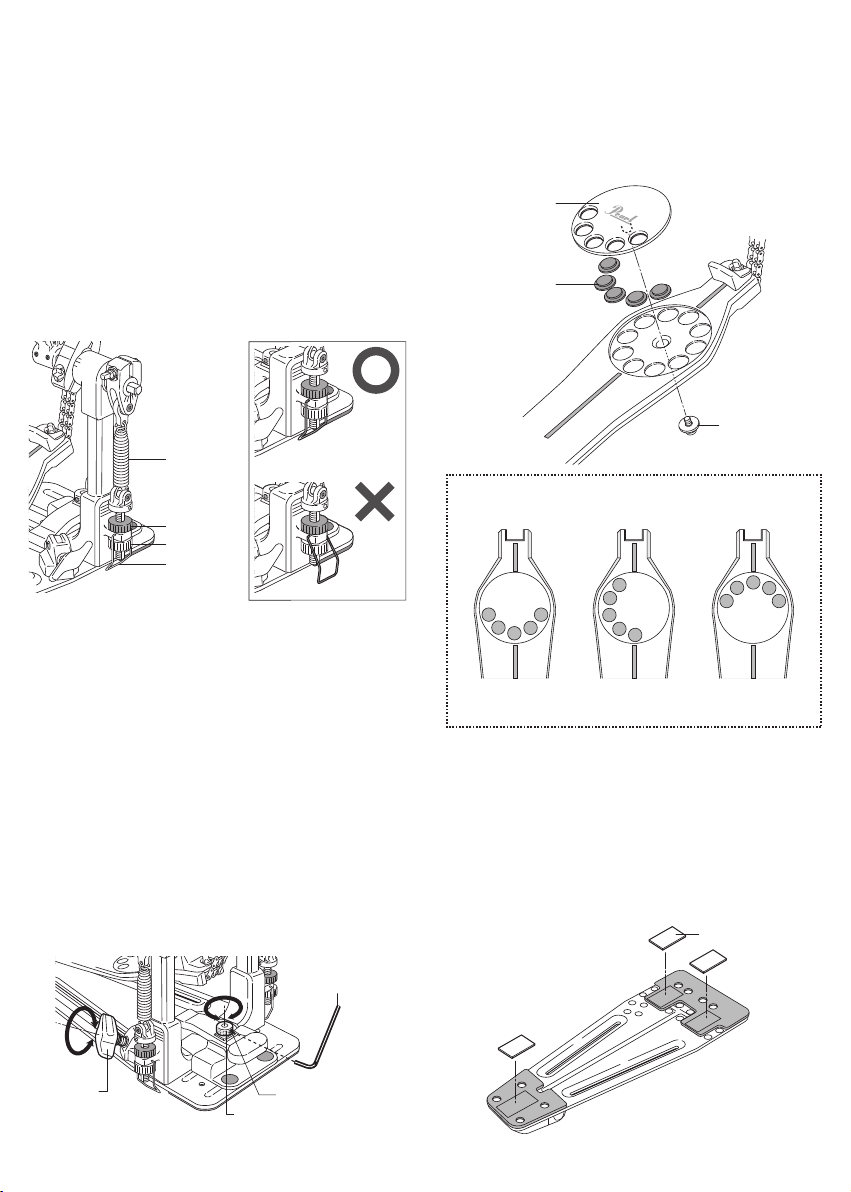

Velcro Strips for Slip Prevention

Velcro Strips are provided with P-3002C Double Pedals to

help prevent slipping when used on carpeted floors. To

apply, peel off the backing on the Velcro Strips and apply

them in the locations shown. Clean the surfaces thoroughly

with alcohol and dry completely for best adhesion (Fig.19).

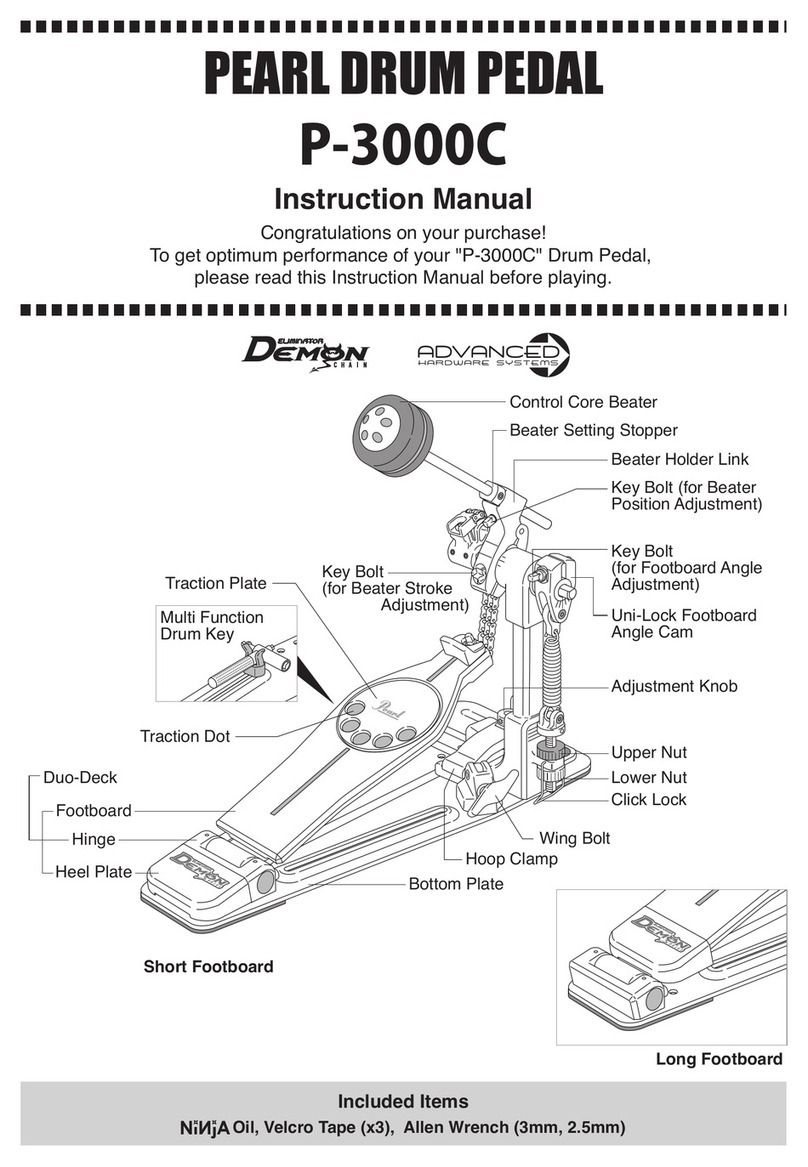

Hoop Clamp System

The P-3002C Hoop Clamp System is designed with

Spherical Rubber Grips allowing the front of the bass drum

to be raised while keeping the pedal flush on the floor.

Insert the bass drum hoop into the Clamp, and turn the

Wing Bolt to secure.

The Clamp comes preset from the factory to accommodate

most bass drum hoops but if necessary it can be adjusted

to fit thicker or thinner hoops. Loosen the Allen Screw on the

Adjustment Knob with the provided Allen wrench (2.5mm)

as shown and tighten or loosen the Adjustment Knob until

proper fit is achieved then re-tighten the Allen Screw

(Fig.17). If the heel plate of the pedal lifts while playing, try

loosening the Adjustment Knob to change the angle of the

Hoop Clamp until the pedal remains flat.

Fig. 18

Fig. 19

Fig. 17

Tip

Setting Examples

The Aluminum Traction Dots can be replaced with optional

NP-283N/7 Rubber Dots for more traction.

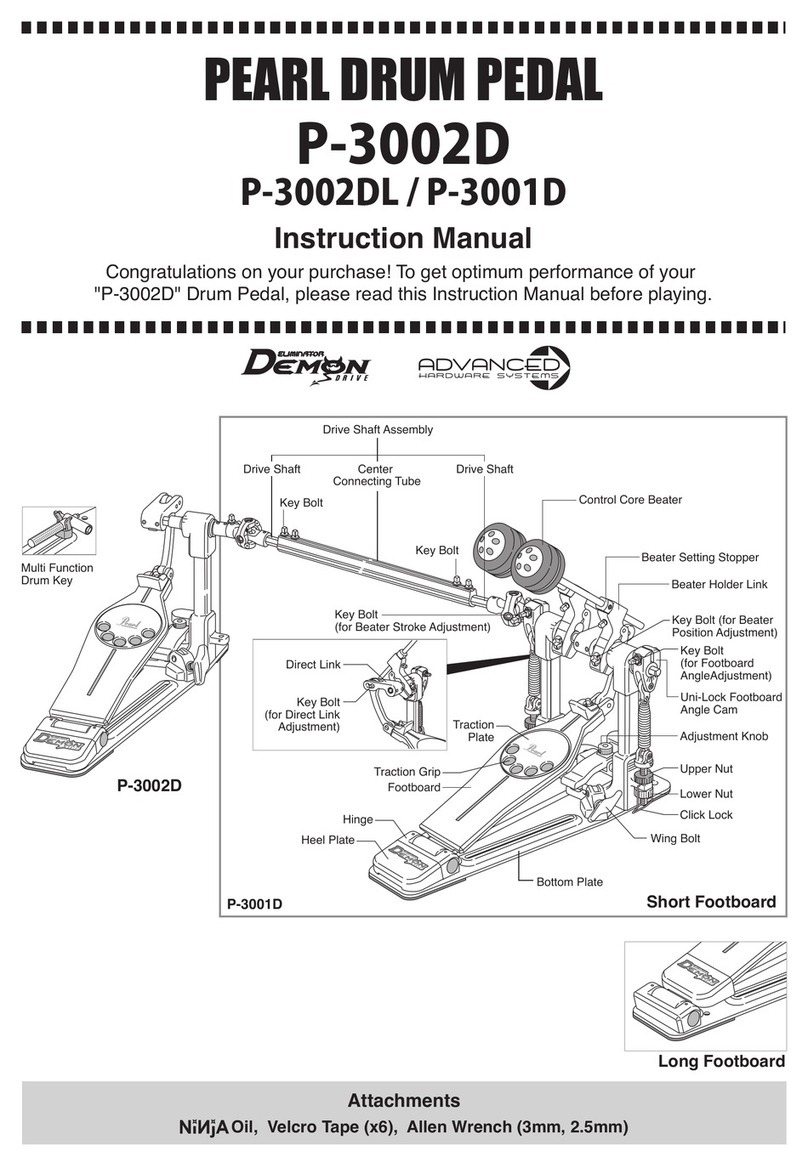

Upper Nut

Spring

Lower Nut

Click Lock

Spring Tension Adjustment

The P-3002C Demon Chain Double Pedal features our

patented Click Lock spring tension retention system. To

increase the spring tension, disable the Click Lock by lifting

the lever upward, loosen the Upper Nut and tighten the

Lower Nut until the desired tension is achieved (Fig.16-A).

To decrease spring tension, disable the Click Lock by lifting

the lever upward, loosen the Upper Nut and loosen the

Lower Nut until the desired tension is achieved. When the

desired spring tension is achieved, tighten the Upper Nut to

keep the spring tension from loosening then press the Click

Lock lever down to engage the grooves around the Lower

Nut until you feel the lever "Click" (Fig.16-B). Before playing,

make sure that both Upper and Lower Nuts are tight and the

Click Lock lever is in a vertical position with both sides of

the lever engaged in the grooves around the Lower Nut.

Fig. 16-BFig. 16-A