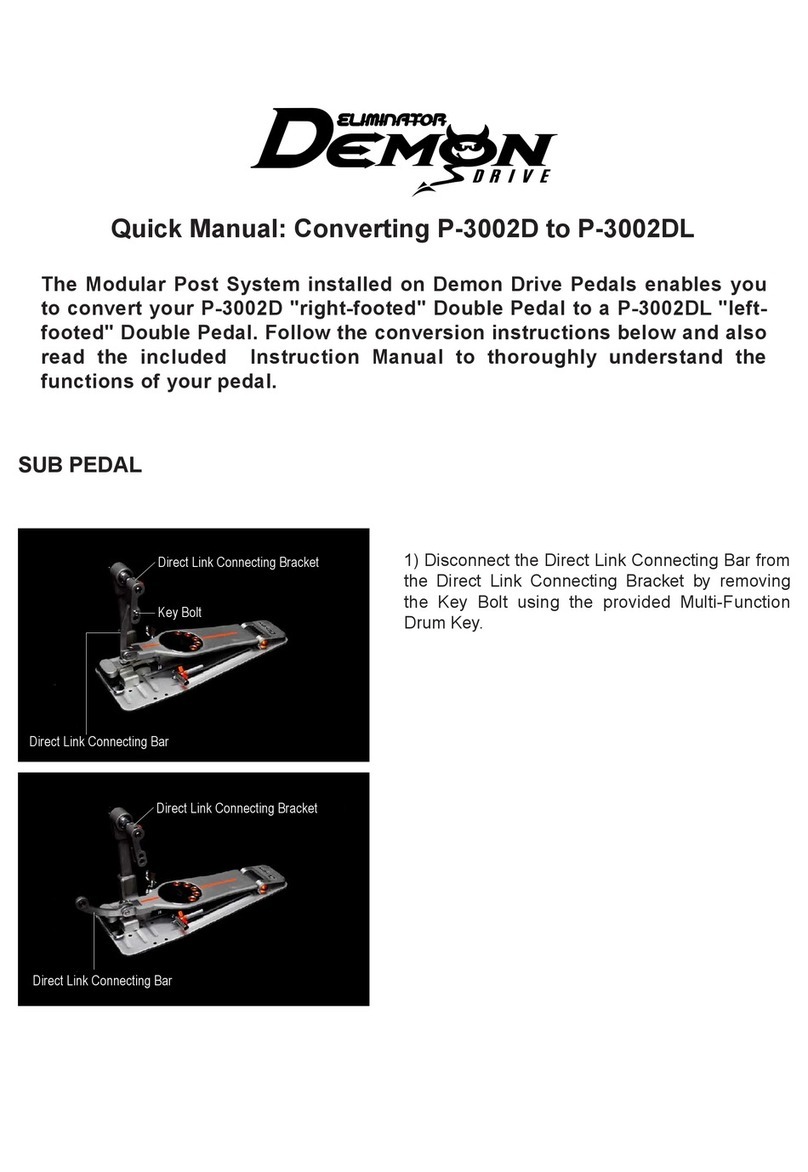

BASIC SET-UP

1. Connect one end of the Drive Shaft

Assembly to the short extension of the axle

of the Secondary pedal as shown. (Fig. A)

2. Connect the the other end of the Drive

Shaft Assembly to the short extension of the

axle on the left side of the Primary pedal as

shown. (Fig. B)

3. Loosen the Key Bolts on the Center

Connecting Tube of the Drive Shaft. Adjust

the distance between the Primary pedal and

the Secondary pedal to your liking.

Re-tighten the Key Bolts. (Fig. C-1)

Note: You may need to rotate the Drive Shaft

Assembly to bring the footboard of the

Secondary (left) pedal to the proper playing

height (angle) before attaching the Drive

Shaft to the Primary pedal.

Now, your P-120P pedal can be used as the

Secondary pedal and be placed on the left

side of the P-121TW.

Please refer to the following Basic Set-up

instructions below for connecting the P-120P

to the P-121TW.

Note: Please retain the parts that were

removed from the P-120P (Spring Assembly,

Beater Angle Cam, and Key Bolt) should you

decide to return it to a single pedal. Please

use the beater from P-120P as the second

beater on the P-121TW.

Fig. A

Fig. B

Note : If the pedals are extended too far, the

Drive Shaft will come apart. Reassemble the

Drive Shaft with the dots aligned as shown in

Fig. C-2.

Optional Pedal Stabilizer (PS-85)

To help prevent the Secondary (P-120P)

pedal from slipping, the PS-85 Pedal

Stabilizer is available separately. The PS-85

features convertible spike/rubber tips and is

attached by the hoop clamp of the Second-

ary (P-120P) pedal.

Fig. C-1

Fig. C-2

Products and specifications are subject to change without notice.

Printed in Taiwan 2004

CAUTION

Take care when handling or moving the

fully assembled Twin Pedal to prevent

damage to the Drive Shaft and its

components.

Periodically check all Allen Screws for

tightness and tighten them with the

provided Allen Wrenches as needed.

Periodically apply lube to all moving parts

such as the Chain, Cam Roller, Footboard

Hinge, etc. for optimal speed and extended

life of your pedal. Bearings should be

lubricated with grease, not liquid oil.

To maximize traction of the rubber mats

underneath the PowerPlate, keep them

clean and dust free using a damp cotton

towel.