LUBE EGH-2C User manual

L-0195

Manually Operated Lubrication Pump

(Models: EGH-C and EGH-P)

Operation Manual

LUBE CORPORATION

Contents

Overview

Page

1. Models of Grease Feed Equipment 1

2. Specifications

2.1 List of Product Specifications

2.2 List of Product Code Numbers for EGH-C and EGH-P

2.3 Name of Each Section

3. Handling for Safety5

3.1 Installation

3.2 Port Connection

3.3 Greases to be Used and Replenishment

3.4 Usage Conditions

3.5 Air Bleeding

3.6 How to Operate the Handle (Operation and P.D.I.)

3.7 How to Replace the Cartridge

4. Pump Operation7

5. Failures and Countermeasures8

6. Causes of Grease Contamination and

Countermeasures

9

6.1 Causes of Contamination

6.2 Countermeasures

- 1 -

Overview

This grease feed equipment is a pump for force-feeding a comparatively small amount of grease manually to each

grease feed point from the distributor (constant-volume pressure-forwarding valve).

1. Models of Grease Feed Equipment

1.1 Name: Manually operated lubrication pump

1.2 Models: EGH-C and EGH-P

2. Specifications

2.1 List of Product Specifications

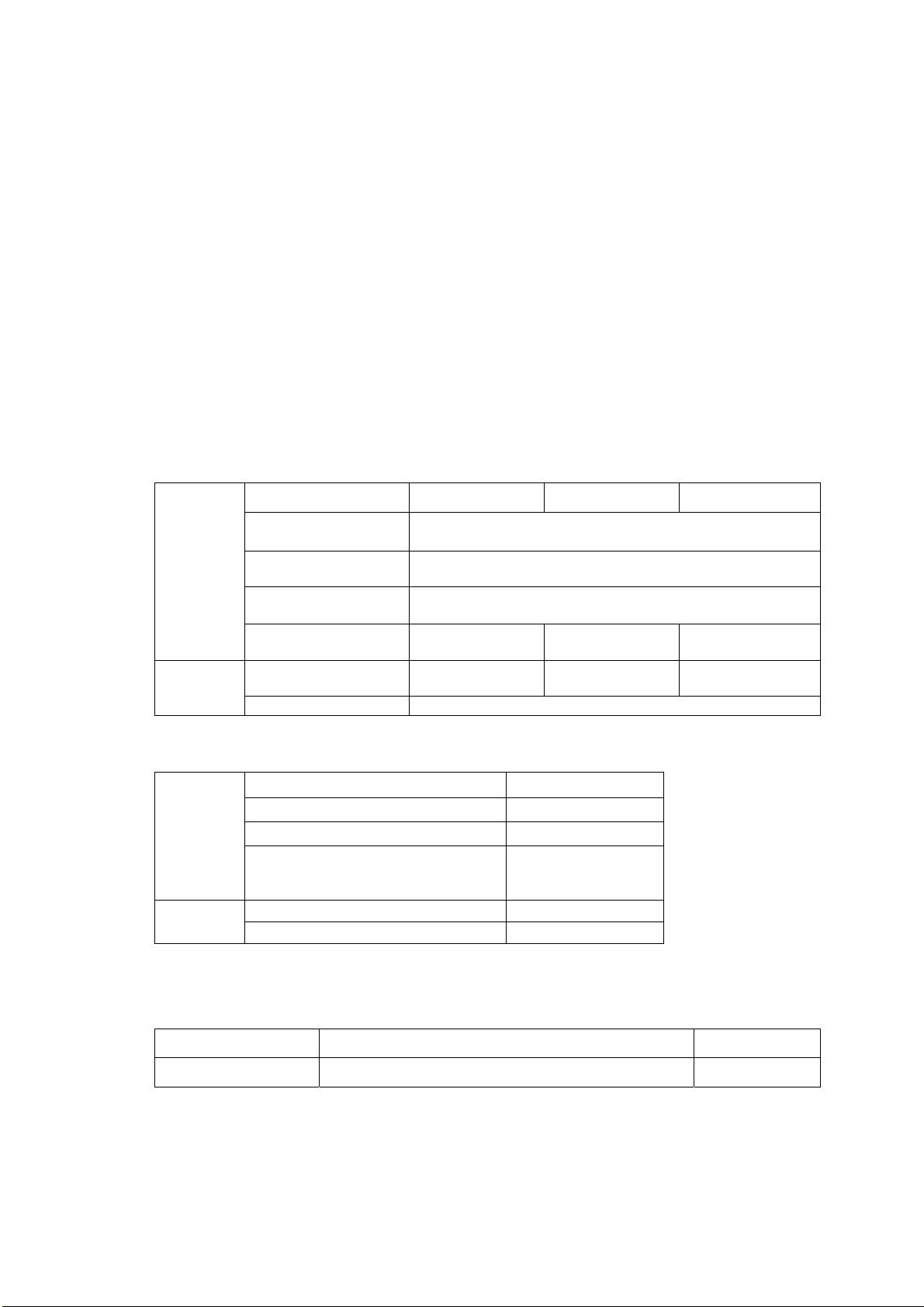

(1) EGH-C and E-GH-P type pumps

Model EGH-2C EGH-4C EGH-4CB

Discharging volume

(m

/stroke) 1

Discharging pressure

(MPa) 10

Pressure reducing

method Operation by the handle

Pump

Tank Cartridge type Cartridge type Cartridge type with

spring

NLGI viscosity

number 0 …* 0…* 0,1

Specified

grease Soap group Lithium family

* NLGI No. 1 may be used only under air temperature of 20°C or more.

Model EGH-3P

Discharging volume (m

/stroke) 1

Discharging pressure (MPa) 10

Pump

Tank Effective capacity

0.26 L

Plastic tank

NLGI viscosity number 000, 00, 0, 1

Specified

grease Soap group Lithium family

* NLGI No. 1 may be used only under air temperature 20°C or more.

(3) Pressure gauge (optional part)

Code No. Pressure range Connection port

109141 25 MPa R1/8

- 2 -

(4) Tank

Code No. Capacity (effective) Material

530377

539131

539133

0.26 L

0.4 L cartridge type

0.4 L cartridge type (with spring)

0.2 L cartridge type

PCTA

Polypropylene

Polypropylene

Polypropylene

(5) Waterproof cap for cartridge (optional part)

Code No. Use Material

530492 Cartridge (with spring) for outdoor use Polypropylene

2.2 List of Code Numbers for EGH-C and EGH-P

Code No. Model Type of Tank Pressure

reduction

103780

103781

103782

103783

EGH-2C

EGH-4CB

EGH-4C

EGH-3P

Cartridge

Cartridge (with spring)

Cartridge

0.26 L

Operation by

the handle

Ditto

Ditto

Ditto

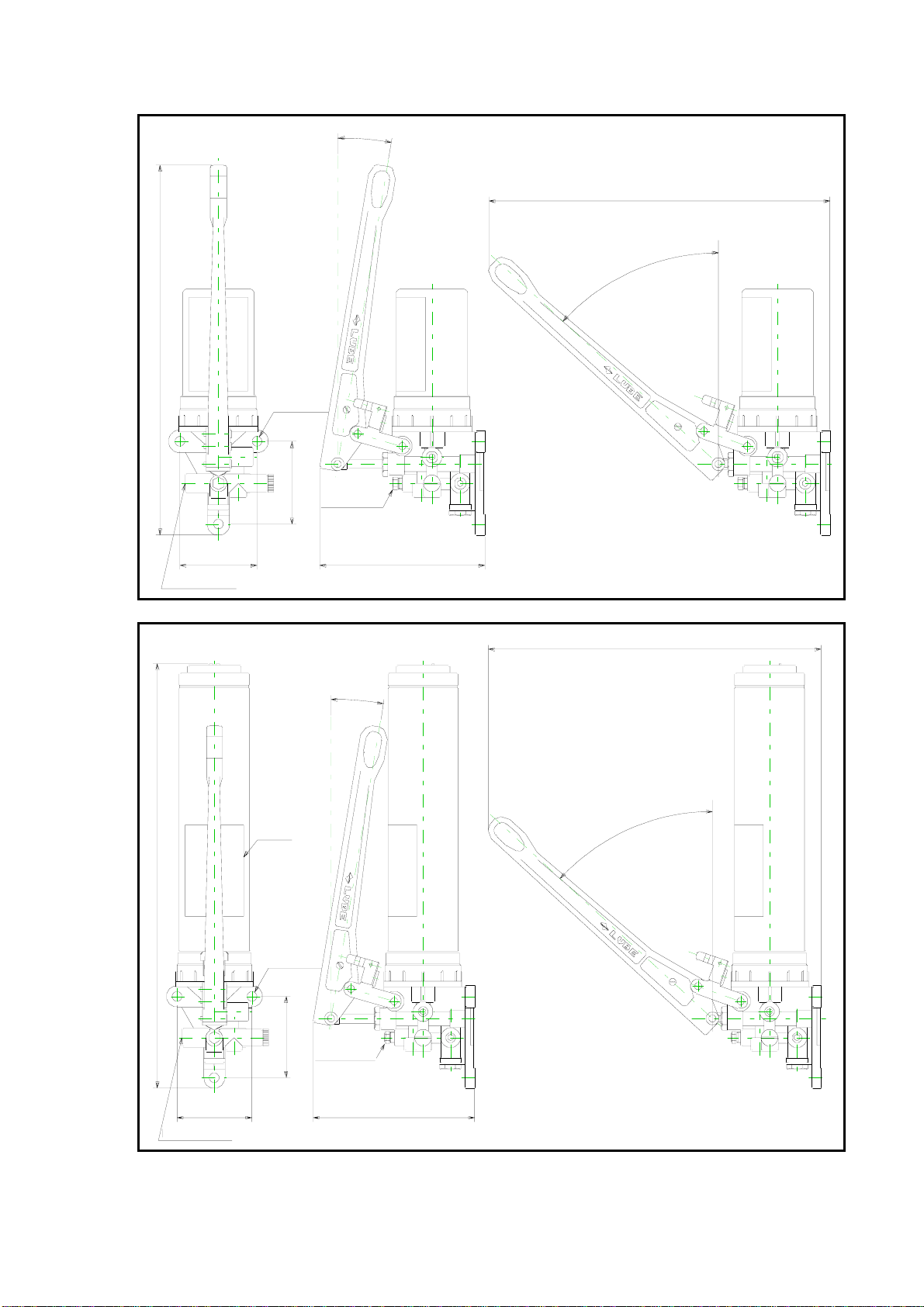

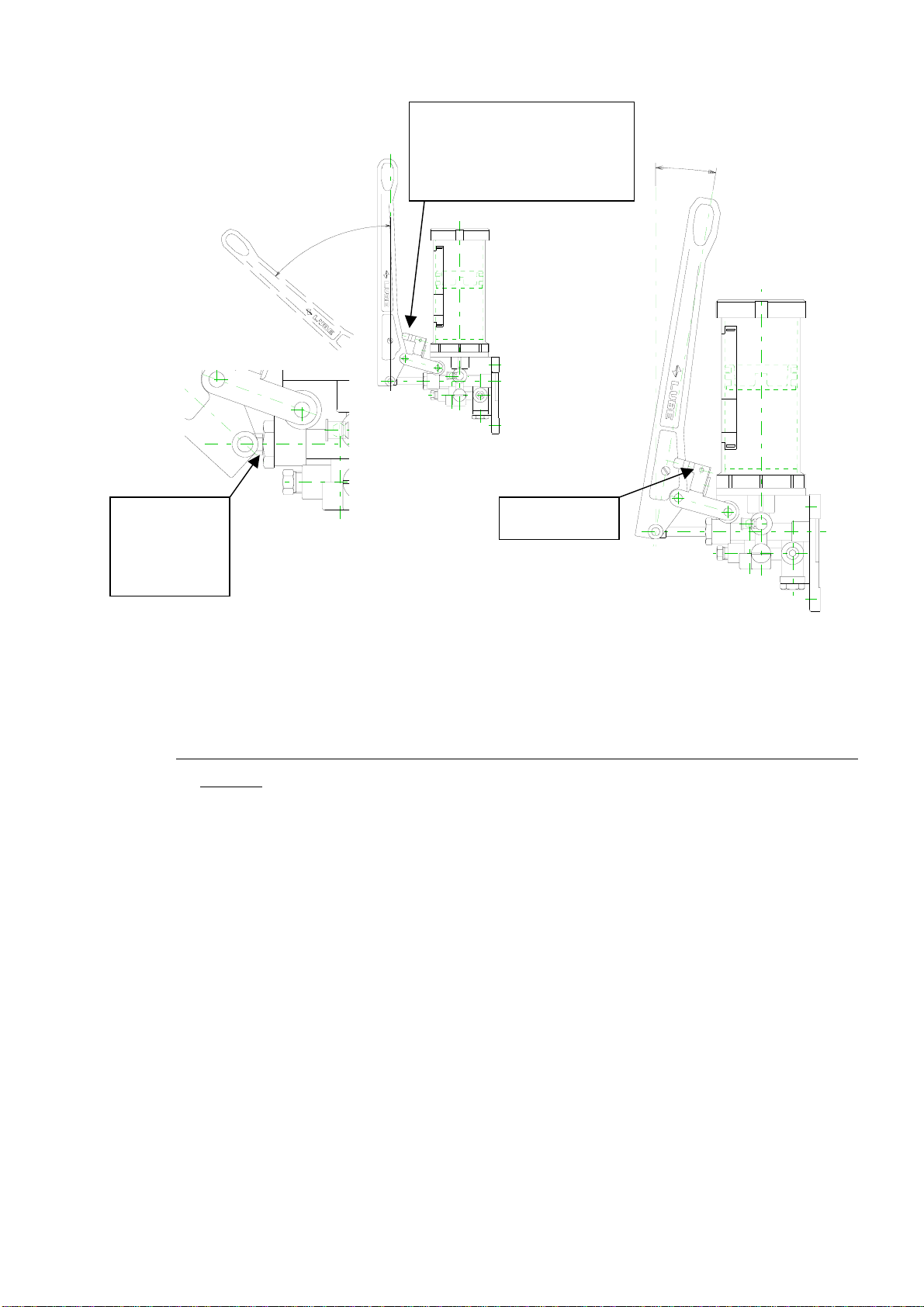

2.3 Name of Each Section

- 3 -

EGH-2C

70

75

3−φ9(穴)

(47.5゜)

(150)

(9.5゜)

エア−抜きバルブ

(310)

吐出口(Rc1/8)

(336)

Hole

Air bleed valve

Discharge port (Rc 1/8)

394

70

75

3−φ9(穴)

(47.5゜)

(150)

(9.5゜)

エア−抜きバルブ

(310)

吐出口(Rc1/8)

注意銘板

Caution plate

Air bleed valve

Discharge port (Rc 1/8)

Hole

EGH-4C

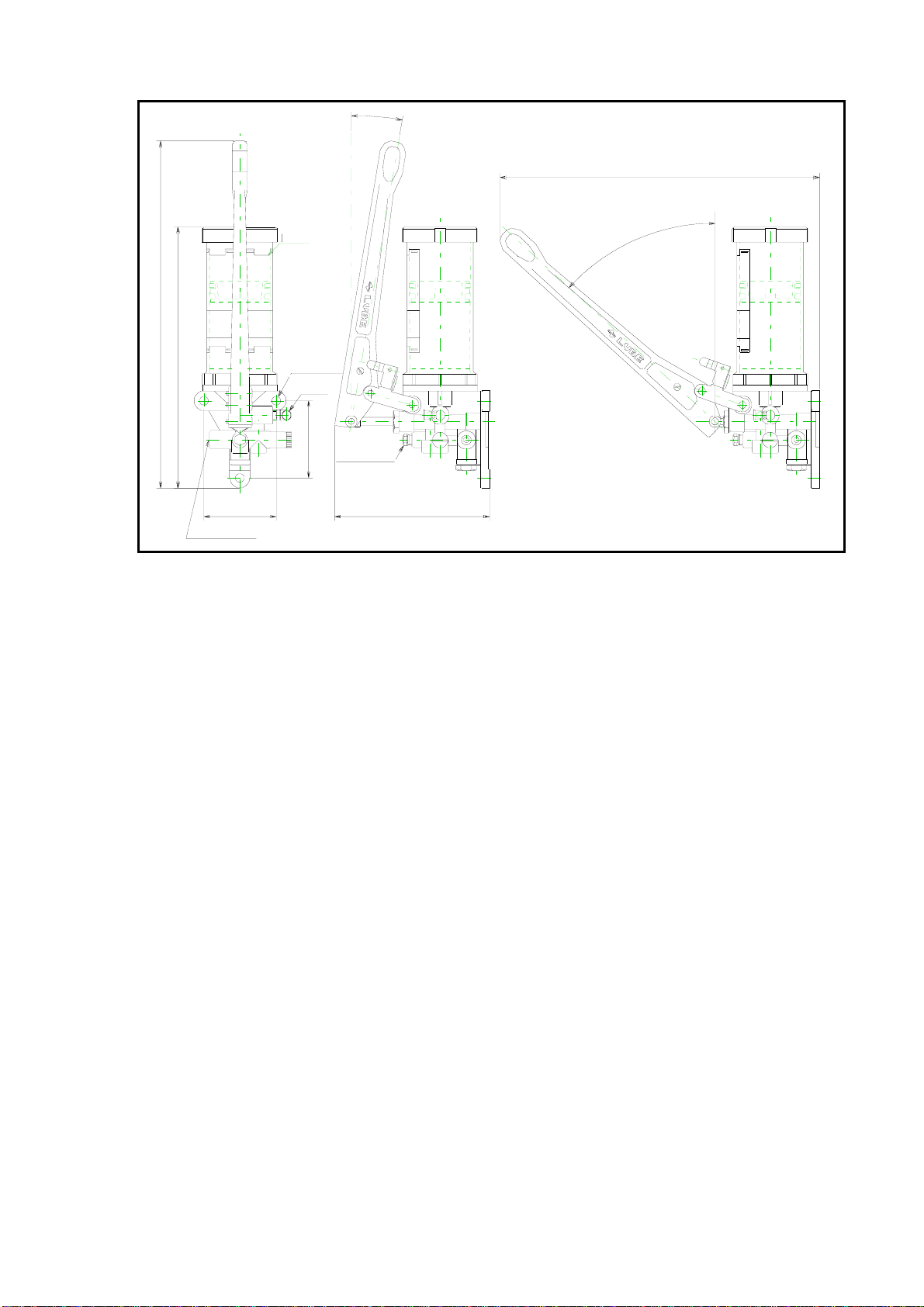

70

75

3−φ9(穴)

(47.5゜)

(150)

(9.5゜)

エア−抜きバルブ

(310)

吐出口(Rc1/8)

336

補給口

253

注意銘板

Caution plate

Replenishing

port

Air bleed valve

Discharge port (Rc 1/8)

Hole

EGH-3P

- 4 -

- 5 -

3. Handling for Safety

3.1 Product Installation

Choose a place for installation that allows easy operation of the handle, etc.

Mount the grease feed equipment on a vertical wall or a flat stand or board and secure it reliably.

Use M8 screws for installation and fix at three points.

If any vibration is expected, do not install the equipment directly but only through a rubber isolator, etc.

3.2 Port Connection

Carry out port connection by tightening with an appropriate torque and make sure that there is no grease leakage.

3.3 Greases to be Used and Replenishment

(1) Grease

Do not use any grease other than those lithium family greases specified in “2.1 List of Product

Specifications” so that no pump failure, clogging of the system, etc. occur.

(2) Replenishment

Standard 0.26 L tank

If the follow plate inside the tank has come down to the low level, replenish grease without fail.

In replenishing, feed grease only from the replenishing port. Otherwise, it may cause a failure. Use

appropriate attention so as not to introduce air, foreign substances, etc.

Cartridge type

If the end of the cartridge container has come down to the low level, replace the cartridge without fail.

Never reuse the cartridge, for example, by refilling it. Otherwise, the cartridge container may burst. Carry

out replacement operation with appropriate attention so as not to allow air, foreign substances, etc. to enter

referring to “3.7 How to Replace the Cartridge.”

3.4 Usage Conditions (When using the equipment, maintain the following conditions.)

Operating ambient temperature 0°C to +40°C

Operating ambient humidity 35% to 85%

3.5 Air Bleeding

After system piping work and when air is introduced into the pump, carry out air bleeding by all means. In

carrying out air bleeding, loosen the air bleeding valve of the pump (return for approximately a turn

counterclockwise) and move the handle to and fro until grease comes out and air stops coming out and, after

completing air bleeding, close the air bleeding valve.

3.6 How to Operate the Handle (Operation and P.D.I.)

(1) Disengage the handle with the handle stop.

(2) Move the handle to and fro to feed grease.

(3) When the handle can no longer be pulled toward you, feeding of grease has been completed. (Completion

of grease feed).

(4) After completing grease feeding, push the handle until it touches the tank in order to reduce pressure. In the

case of EGH-2C, the handle does not tilt to the extent it touches the tank. If pushed toward the tank, it stops

moving forward. Stop pushing at that point.

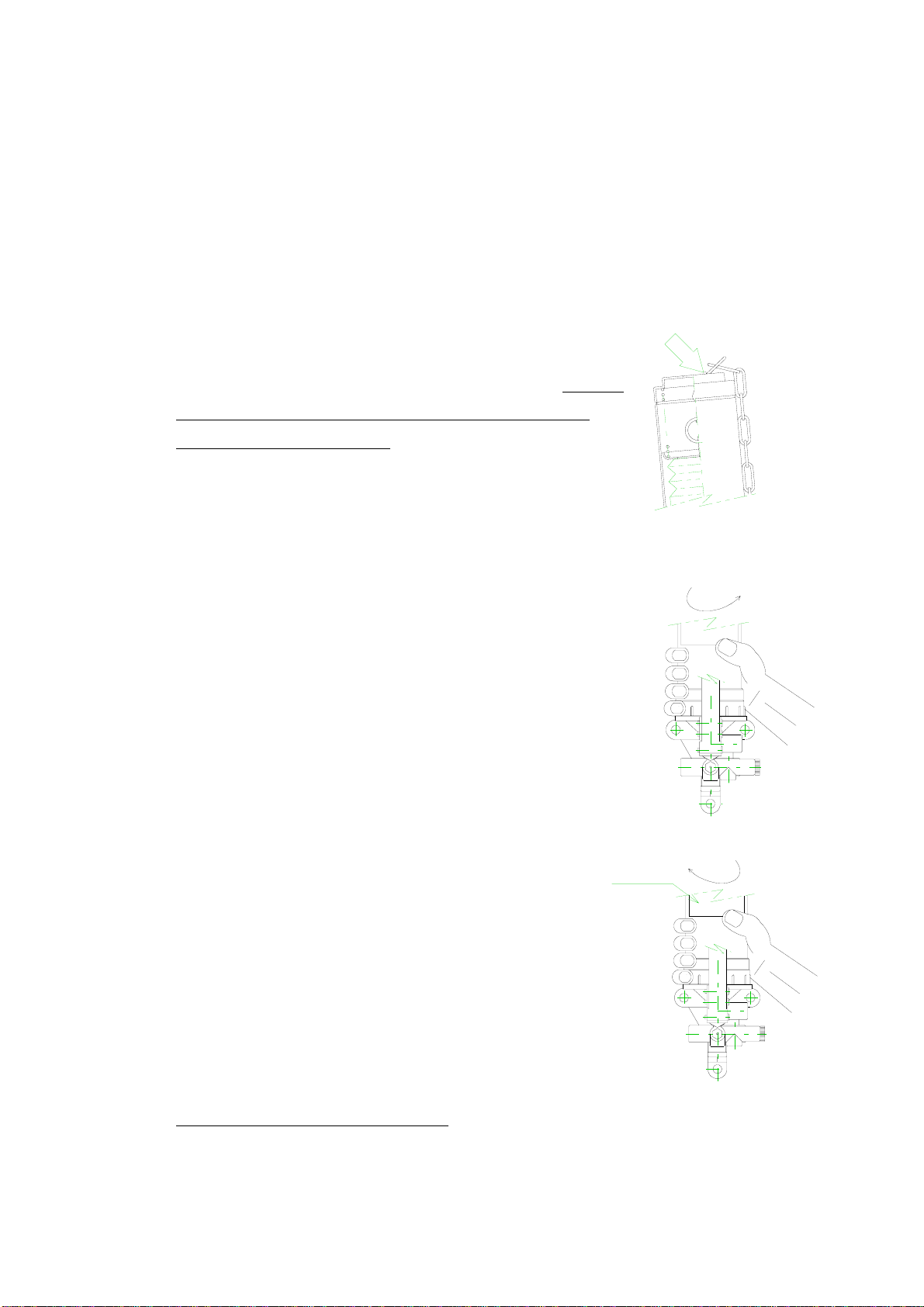

3.7 How to Replace the Cartridge (only for cartridge type models)

(1) Pull up the chain (so that a new cartridge can be inserted) and hook the

chain to the tab on the top of the cover (the point indicated by the

arrow in the drawing on the right).

(2) Turn the cover by hand and remove it from the pump.

- 6 -

(3) Remove the empty cartridge from the pump, and mount a new

cartridge paying appropriate attention so as not to allow air and foreign

substances to enter.

注意銘板

Caution

plate

* Use the same brand and same grade of grease.

(4) Mount the cover to the pump again and tighten it by hand.

(Position in which the seal comes to the front)

(5) Pull up the chain to remove from the tab and move it down slowly.

Note: Put the chain completely in the cover.

Note: For types without a spring, steps (1) and (5) are not necessary.

4. Pump Operation

Figure 1

Detailed drawing

(47.5゜)

(9.5゜)

During operation, if the handle touches

the handle stop, do not push in an

y

more, but pull it.

Handle stop

The piston and the

grand nut touch

each other

(1) Disengage the handle with the handle stop

(as shown in Figure 1).

Figure 2

(2) Feed grease by moving the handle to and fro.

* Pulling the handle to you sets the system to discharge operation and pushing it sets the system to sucking

operation.

(3) Grease feed operation is completed when the handle can no longer be pulled toward you. (The handle can

be pulled toward you until the stepped portion of the piston shown in Figure 1 touches the grand nut. Refer

to the detailed drawing.)

(4) When pushing the handle during operation, stop the handle when the handle touches the end of the handle

stop. (At this point, the handle is approximately parallel with the tank.)

(5) After completing grease feeding, push the handle until it comes into the status shown in Figure 2 for reducing

pressure (Figure 2). Under this status, the handle is locked to the handle stop. Then, stop pushing the

handle.

- 7 -

- 8 -

5.

Troubleshooting and Measures to take

TroubleCauseMeasures to take

Little grease left in the reservoir. Refill the reservoir or replace cartridge

with the same or equivalent grease.

Air in the pump. Bleed air.

No grease discharged

from pump

Insufficient move of the handle. Move the handle until it does

not move.

No grease discharged from pump

due to any of above causes.

Refer to above measures.

Air in the tubing. Take off closure plug(s) at the end

and operate pump and bleed air in

the tubing.

Foreign particle(s) at the Ball seating

section of relief valve.

Contact LUBE

Pump discharge pressure is low due to relief

valve’s wrong pressure setting.

Contact LUBE

The relief valve pressure has been set

before shipment.

Grease leaking from pump discharge port

or pipe connection parts.

(Due to looseness or excessive tightness)

Tighten them with proper torque or re-pipe

them.

Damaged tubing. Replace damage tubing.

Pressure in main tubing

is not built up

Handle is pushed to reservoir too much.

(Depressurize valve is opened.)

Operate the handle at correct range.

Air in the system due to above reasons. Refer to above measures for“Air in the

pump”and“Air in the tubing”.

Air in the system

Due to low level of grease in tank or

cartridge, air is introduced into pump.

Refill reservoir with same or equivale

nt grease or replace cartridge and then

bleed air.

Clogged valve(s) Replace valve(s)

No grease discharged from

valve(s) No grease is filled in tail tubing. Fill tail tubing with grease at installation.

This manual suits for next models

7

Table of contents

Other LUBE Water Pump manuals

Popular Water Pump manuals by other brands

DUROMAX

DUROMAX XP WX Series user manual

BRINKMANN PUMPS

BRINKMANN PUMPS SBF550 operating instructions

Franklin Electric

Franklin Electric IPS Installation & operation manual

Xylem

Xylem e-1532 Series instruction manual

Milton Roy

Milton Roy PRIMEROYAL instruction manual

STA-RITE

STA-RITE ST33APP owner's manual