DOUBLE ARRAY seriesUser’s Manual

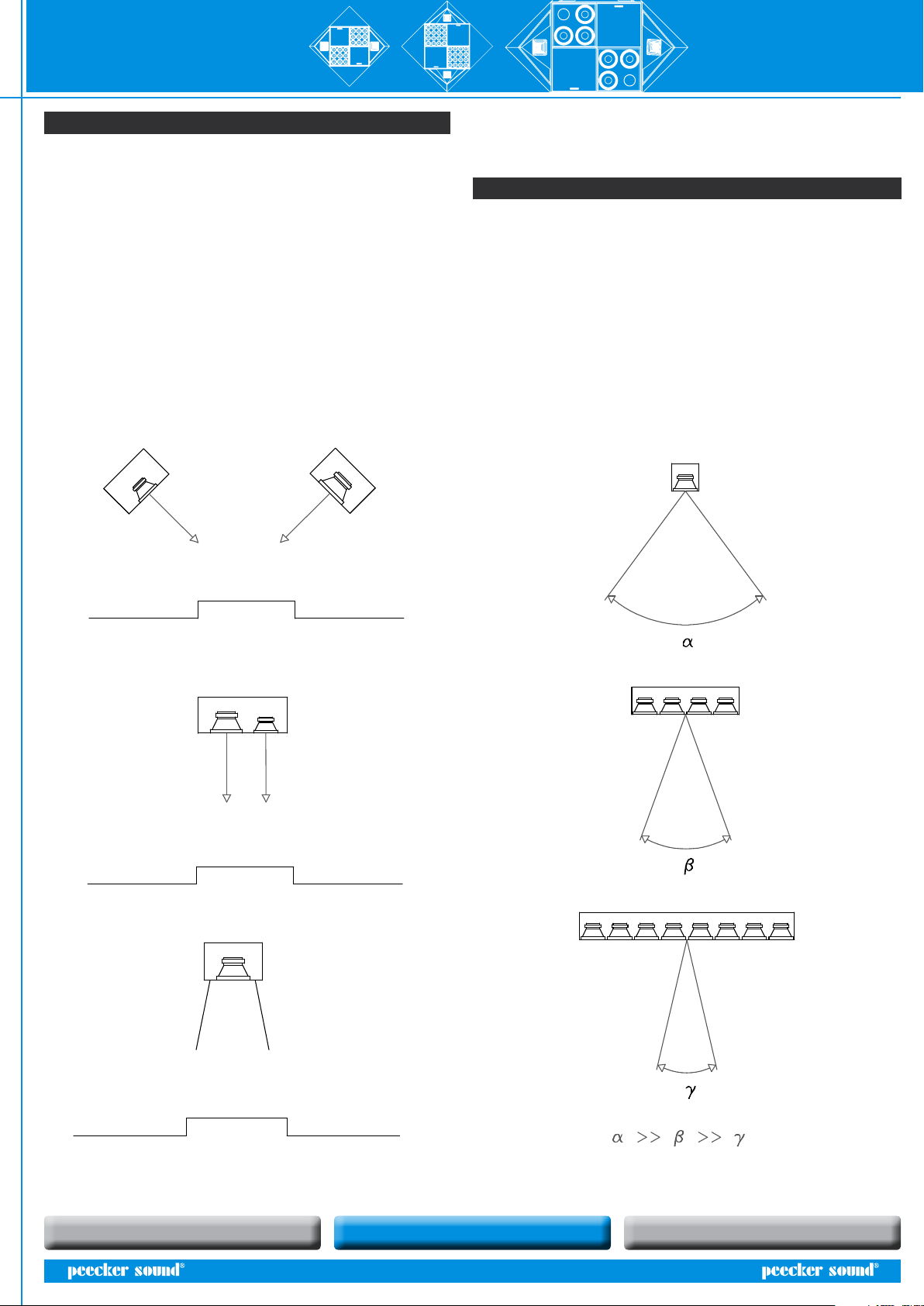

SOUND REINFORCEMENT ACOUSTIC RESEARCHCONTROLLED RADIATION

10

Here below is a brief description of the design steps and the contributions of

the various parties involved in the project:

• After the first meetings, it was decided to “release” the customers, because

they already extensively outlined the problem in terms of relationships both

with the neighbourhood and with the inspectors (USL agencies) checking

on noise emissions. Moreover they all eagerly, already accepted to host and

install a zero series of the new product;

• Of course the R&D Department extensively joined the Engineering

Department throughout the entire design project and its contribution

turned out very conclusive in the selection of the raw materials and above

all in the implementation of controlled-radiation, double-array sound

reinforcement system (an absolute innovation at that time, as the actual

state-of-art in the reference field only accounted for single arrays!);

• On the contrary, the contribution of the suppliers continued over a longer

period of time and led to the following conclusions.

For indoor loudspeakers (by CIARE S.r.l.): standard components out of the

actual catalogue would have been used.

For tweeter horns (by B&C SPEAKERS S.p.A.): bespoke parts and components

would have been designed for the new product by means of a special

dedicated injection and stamping line.

For protection grids (by NUOVA LAMM): new custom-made grids would

have been designed in accordance with CAD drawings of the new product.

For the packaging (by TITAN): the project management approved an

inhouse make due to the expensive price offered by the supplier.

• A very crucial task was performed by the carpenters in terms of scraps

management and selection of the original raw material: marine plywood

(a renown, very light and waterproof material largely used in the navy field)

was selected and it was decided that the size of the speaker central element

(see below) was to be exactly the same as one half of the original raw panel

size (so to avoid any complicated and costly nesting of the wood shapes!);

• The staff from the Electronics Department was immediately asked by the

project team to develop a dedicated electronic controller for the new-born

speaker.

As a matter of fact, it became progressively clear since the very first work

hours that it would have been impossible to accurately reproduce the entire

music range (from 30 to 18,000 Hz) for every possible volume level.

The plan was to design a totally new active crossover that eventually turned

out to be our DP 60-120;

12

◊l’apporto degli operatori della falegnameria fu decisivo per quanto

riguarda la gestione degli sfridi e per la scelta del materiale grezzo di partenza:

si decise di utilizzare del multistrato marino (noto per le sue doti di leggerezza e

impermeabilità, viene spesso impiegato nelle imbarcazioni) e si stabilì, inoltre,

che la dimensione dell’elemento centrale del diffusore (vedi dopo) sarebbe

stata pari esattamente alla metà del pannello iniziale di materiale grezzo

(evitando così un elaborato e costoso processo di nesting delle sagome di

legno!);

◊lo staff proveniente dalla Divisione Elettronica venne subito chiamato in

causa dai membri del team di progetto perché si sentiva l’esigenza di realizzare

un controller elettronico dedicato al diffusore nascente.

Infatti, fin dalle prime ore di lavoro sul progetto, si era andata delineando

l’impossibilità di riprodurre fedelmente tutta la gamma musicale (da 30 a 18000

Hz) per ogni possibile livello di volume.

Si sarebbe progettato ex novo un crossover attivo: il futuro DP 60/120;

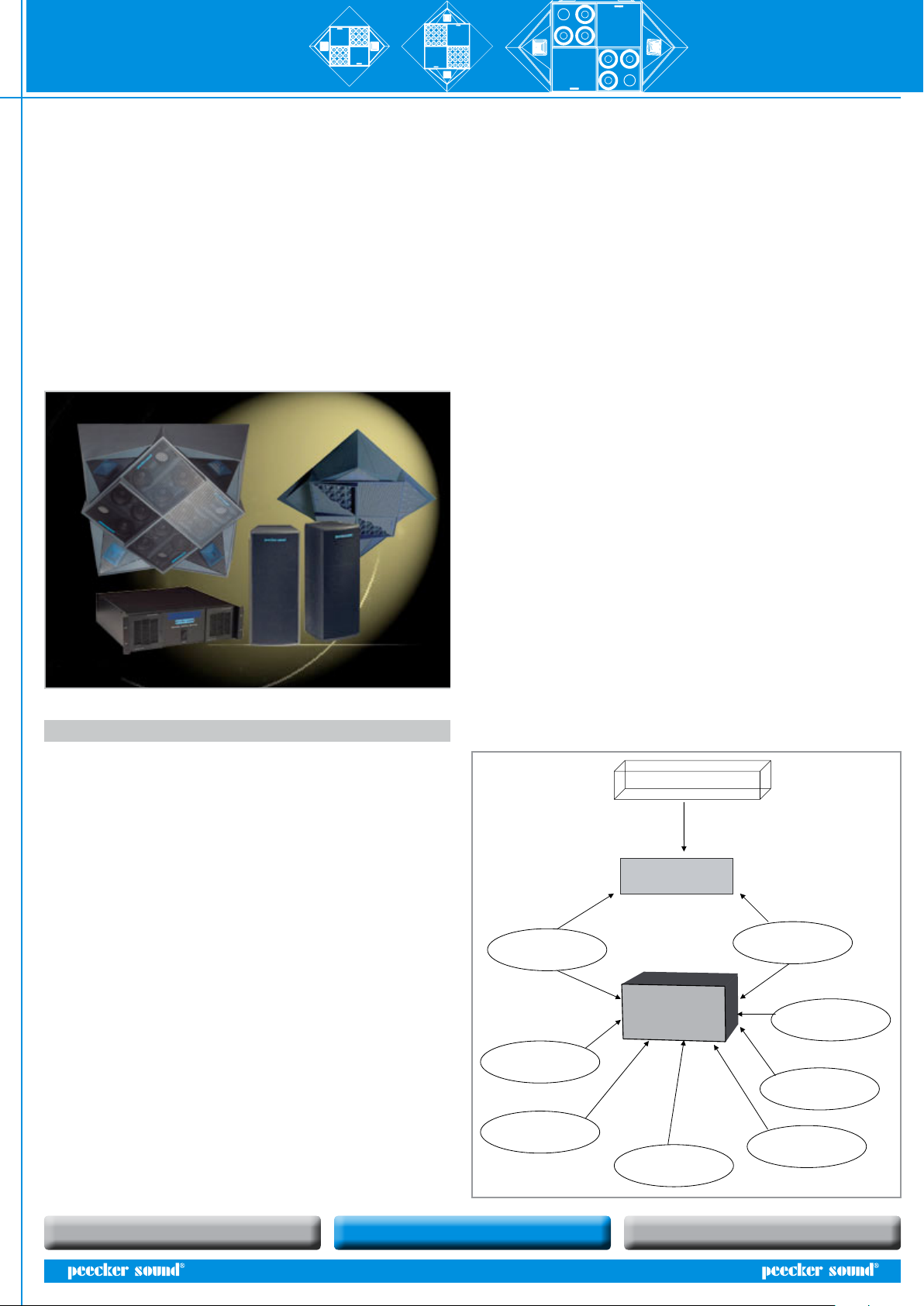

Fig. 4 Il processore DP 60/120

• The production technicians, instructed by the Engineering Department,

decided that a dedicated line would be installed at the premises in Reggio

Emilia where the new product would be assembled.

It was decided that no additional production machineries would be

required, except for electric parts and fabrication tools as for instance

drills, screwdrivers, etc… The same production technicians agreed with

the carpenters on the correct position of holes on the speaker in order to

rapidly achieve an ergonomic placement of electric cables;

• Finally, the sales manager from the Sales Area extensively

cooperated with the Design Engineers to provide the lowest

possible fabrication costs and to outline an attractive speaker look.

In the framework of this collaboration, it was decided that the

speaker was to be equipped with some strobe lights in the corner

elements without active music components (this was the only

suggestion accepted by the project staff among several ones made

by the marketing experts!).

13

◊i tecnologi di produzione, su suggerimento della Divisione Progettazione,

decisero che l’impianto di Reggio Emilia avrebbe ospitato una linea dedicata

per l’assemblaggio del nuovo prodotto.

Si decise, inoltre, che non sarebbe stato necessario un aumento dei macchinari

di produzione, se non in termini di minuteria elettrica ed utensileria di

fabbricazione come trapani, avvitatori, etc… Gli stessi tecnologi di produzione si

accordarono con gli operatori della falegnameria per un corretto

posizionamento dei fori del diffusore al fine di ottenere un rapido ed ergonomico

posizionamento dei cavi elettrici;

◊infine, i sales manager dell’Area Commerciale si prodigarono con gli

ingegneri della Progettazione per contenere il più possibile i costi della

fabbricazione e per tracciare le linee estetiche del diffusore: proprio grazie a

questa partecipazione si decise che il diffusore sarebbe stato provvisto, negli

elementi angolari sprovvisti di componenti musicalmente attivi, di alcune luci

stroboscopiche (fu l’unica proposta che venne approvata dallo staff di progetto,

fra le tantissime formulate dagli esperti di marketing!).

Fig. 5 Schizzo del diffusore nascente

At the end of the design process (that lasted approximately 6 months and

therefore 6 months well ahead of the expected deadline!) the following

specifications had been outlined:

To great satisfaction of the Corporate Management, the first prototype

was ready one month only after defining of the technical specifications

and it proved quite positive although the following modifications were

decided:

1 Using shorter PVC tubing for playing bass chords;

2 Changing the corners of the tetrahedral elements;

3 Redefining the cutting frequencies of the passive crossover.

After saving the modifications in the product folder, the required

production tooling was implemented, the final details were defined and

the part list was laid out including all outsourced parts.

The first zero series was released after production tooling (8 months after

project start-up!) and was installed in a famous club in the district

of Modena. The zero-series obtained immediate customers’ favour.

However, it was decided to hold-on with final production as the Corporate

Management first wanted to apply and obtain both Quality Certification

and Patent (finally awarded only 15 months after application) in order

to prevent copies or reverse engineering problems (which nevertheless

occurred after the large scale success of the Double Array speakers!).

Figure 4. DP 60/120 processor

Figure 5. Sketch of the new speaker

Project team Decisions made Specs/Processes

Engineering Dept.

Management of the

project team

System design

R & D Raw material

and array system

/

Production Dept. Dedicated series Series tooling

Electronics Dedicated controller Totally new design

Carpentry

Chassis - 125x125 cm

No tooling

Grids supplier

Dedicated grids

Design from CAD

drawings

Components supplier

Catalogue components

/

Enclosure supplier

Too expensive packaging

“Make” decision

Marketing

Product look and lights Lights addition

Customers

Availability of the

zero-series

/