SOUND REINFORCEMENT CONTROLLED RADIATION ACOUSTIC RESEARCHCONTROLLED RADIATION

User’s Manual FORTY series

5

6. SYSTEM INSTALLATION

6.1 Floor stacked or suspended installation?

There are some arguments in favour of oor-standing installation and

some in favour of suspended installation, depending on the situation

in hand. Without taking into account possible logistical or visual issues,

which have to be assessed individually, the positive aspects of floor

stacking are mainly associated with stronger overall coupling of low

frequencies with the oor, which boosts eciency at the lower end of

the sound spectrum and increases the eectiveness and speed of the

response to low transients. This is partly because, in the case of oor-

stacking, the speaker cabinets are generally more physically constrained

than in suspended systems and are consequently more stable and rmly

anchored to the ground, which prevents part of the acoustic energy

from being transformed into structural motion and eectively being lost.

Another point in favour of oor stacking is the fact that, from a“spatial”and

“psycho-acoustic” perspective, the sound physically comes from points

close to the stage and thus close to the music scene.

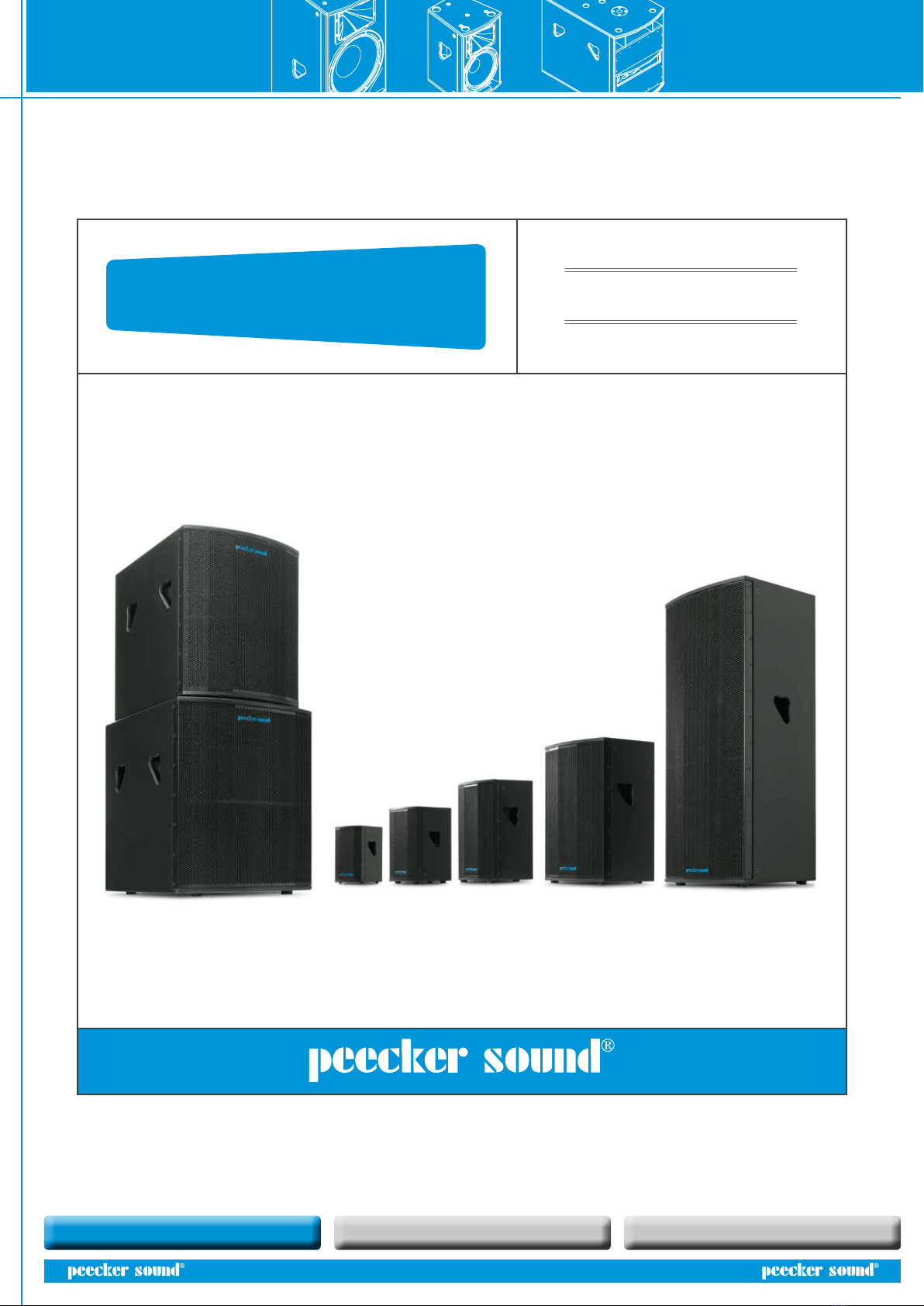

Figure 7. Stack installation of Forty speakers

The choice of suspended speakers (flying system), on the other hand, is

obligatory in all cases where oor stacking fails to provide the required

sound coverage. When the mid-high frequency transducers are not high

enough above the listeners’ heads, high frequencies will be poor even at

short distances due to both the “friction”of sound on the audience (since

it is a sound absorption factor) and sound refraction phenomena caused

by the vertical temperature gradient created by the audience itself.

Therefore, oor installation is not generally very suitable for covering

substantial distances (the problem is reduced when the audience is

arranged on a sloping plane and the level of the listeners furthest away

is considerably higher than those in the front rows). Moreover, for long

distance coverage, providing sucient SPL (Sound Pressure Level) to the

rows at the back may result in excessive SPL on the front rows. In this

case, ying installation is to be preferred since, reducing the dierence in

distance from the system of close and long range listeners, it will reduce

the SPL gap and spread the sound more evenly.

6.2 Positioning angles

When installing more than one Forty Series speaker at the sides of the

stage, particular care must be taken to position them at the correct angles.

The high frequencies delivered by the horns of each speaker can in fact

cause negative interferences with those of the others at certain points or

in particular spatial directions. One way of containing this phenomenon

is to tilt the speakers in relation to each other by specic angles related

to the dispersion angle of the sound beam delivered by their individual

horns - this is correct for both vertical and horizontal tilting.

One specic technique is to tilt the two speakers by an angle close to, or not

excessively lower than, the horn’s dispersion half-angle. In this way, by shifting

slightly away from the axis of the system made up of the two coupled speakers,

the contribution of one of the two will become negligible compared to that of

the other, thereby avoiding any harmful interferences. Conversely, a narrower

dispersion angle can be achieved by bringing the long sides of the speakers

closer together, resulting in a narrower coverage and a longer throw, but with

a less even spread at close range.

The choice will therefore be guided by the shape and size of the area requiring

sound coverage.

7. PASSIVE LOUDSPEAKER SYSTEMS

The Forty Series comes in both passive and amplied versions.

The passive loudspeaker systems have particularly selective crossover lters

to achieve the most natural timbre quality at mid frequencies, which are

important for the intelligibility of speech and vocals and to deliver the clearest

possible sound and music. This is particularly useful since it makes it possible

to obtain top quality sound from the 4008, 4010MH, 4012MH, 4015MH, and

4030MH speakers without the need for an external processor: all plug and go!

The use of a processor is clearly essential for the active crossover function in

cases of multi-amplication, e.g. with all the complete subwoofer systems.

In the latter case, the delay function will allow the correct sound alignment

between the subwoofers and the upper modules. The processor is useful in

all cases requiring not only top quality sound but also speaker protection

whilst taking full advantage of its maximum output, which is a key concern in

professional sound installation. It is important, in fact, to control the amplier

input voltage so as not to damage the speaker passive components with

signals that are too powerful or otherwise unsuitable for acoustic transducers.

The following paragraph explains how and why this is the case.

Upstream, i.e. acting on the amplier’s input audio signal, it is clearly not

possible to protect the speakers from harmful phenomena originating from

the amplier itself. If an amplier malfunction generates constant or extremely

low frequency voltage (DC), this will damage the transducers regardless of the

input signal. Similarly, high voltage peaks due to switching on and o devices

upstream from the ampliers when the ampliers are operating can also

damage the transducers. Therefore, to power an electro-acoustic system, it is

important to switch on the ampliers only after the power supply to the mixer and

control electronics has been turned on and has stabilized. To turn o the system,

the reverse sequence applies, so the power amplier should be switched o rst.

We strongly recommend control and maintenance of the sound system and

strict adherence to the correct power on/o sequence of the devices making

up the audio chain.

7.1 Amplication and limitation

Generally speaking, excessive power can easily damage transducer coils due

to the overheating it causes (high RMS values for long periods of time), while

in rare cases it can damage the mechanical parts of the cone (membrane or

suspensions). In this specic case, frequencies lower than the reex tuning

frequency can cause excessive excursions (that are also pointless since the

eciency value of these frequencies is virtually nil) and consequent damage.

It is therefore advisable to always use external processors which, with the

due frequency cuts and limitations, will protect the woofer and optimize its

eciency.

The signal sent to the high frequency drivers of the Forty Series, however, is

passively protected by a special lament device. It is the user’s responsibility

not to supply a passive speaker with signals that are damaging to the

transducers. To control these signals, Peecker Sound recommends using the

PS266 processor. Using the appropriate selection of ampliers and limiters

allows speakers to achieve maximum performance without the risk of damage.

For maximum performance – i.e. exploiting transducers to the full in relation

to signal peaks – a good practical rule is to have a double-powered (“oversized”,

as we call it) amplication channel as compared with the transducer’s RMS power

tolerance. To protect the transducer coil, moreover, a limiter also needs to be

used to avoid exceeding RMS power levels for prolonged periods of time. This

is the function performed by the limiters in the Forty Series amplied models

and in the PS266 external processors.

4015MH/A 4015MH/A

40SW18/A 40SW18/A