Pegasus VIACLIN User manual

SERVICE MANUAL

LFT5508

Issue 3

VIACLIN

Alternating Pressure Mattress Overlay

Model 2502

LFT5508 - AMENDMENT RECORD

REVISION

CHANGE

NOTE

TECH.

NOTE BRIEF DETAILS SIGNATURE DATE

1

2

3025/02 011/02 To have a common flow restrictor assembly for 2503 &

5202 K.Wilson 3/9/02

023/02 -Replace part number MEC483 with MEC14753 K.Wilson 16/9/02

- - Redrawn instruction diagrams to show overlay straps

around mattress. K.Wilson 3/10/02

- - Reformated Viaclin service manual 2502 so that it is

similar in structure as the newer manuals. Changed text

‘5.5 ltr/min’ to ‘6.5 ltr/min’. Added note”EXISTING 2501

OR 2502 THAT REQUIRE A REPLACEMENT

POWERUNIT WILL BE REPLACED BY A 2503 POWER

UNIT (SA242) AND AN APPROPRIATE ADAPTER (REF:

MOD KIT MOD14831)”. See IU 088/02

K.Wilson 22/10/02

POLICY STATEMENT

Pegasus Ltd has a policy of continuous product improvement and reserves the right to change details presented in this

Service Manual without notice.

Tel: +44 (0) 23 9278 4200

Fax:: +44 (0) 23 9278 4250

E-mail: [email protected]

Web Site: www.pegasus-uk.com

LTF5508 iIssue 3

VIACLIN MODEL 2502 Oct 02

LIST OF CONTENTS

Section Title

1. SAFETY STATEMENT

2. INTRODUCTION

General

System Description

3. SETTING UP/OPERATION

Setting Up

Profiling and Knee-Breaking

Moving the Bed and Power Cuts

CPR (Cardio Pulmonary Resuscitation)

Deflation, Removal, Carrying and Storage

Alarms and Fault Finding

4. CONSTRUCTION OF PRODUCT

Major Elements of the System

Mattress

Power Unit

Technical Details

5. INFECTION CONTROL AND CLEANING

Infection Control

Cleaning Guidelines

6. EQUIPMENT MAINTENANCE

General

Power Unit

Mattress

7. TEST EQUIPMENT

8. PARTS LIST

Power Unit

Mattress

LFT5508 1.1 Issue 3

VIACLIN MODEL 2502 Oct 02

SECTION 1 - SAFETY STATEMENT

1.1. The VIACLIN system must be used in accordance with the manufacturer's instructions.

1.2. The mains electricity supply within the building where the VIACLIN system is to be used must comply

with IEE Regulations.

1.3. Only personnel trained or formally approved by Pegasus Ltd in operation and maintenance of Pegasus

systems may perform maintenance, modification or repair work on Pegasus Ltd Power Control Units.

1.4. Unqualified personnel attempting to work on Pegasus Ltd Power Control Units risk serious injury to

themselves and others, and possibly death by electrocution.

Do not work, or attempt to work on Pegasus Power Units unless you are properly qualified

to do so.

1.5. Pegasus Ltd systems are designed to comply with all relevant electrical safety, manufacturing and

performance standards published by IS0, IEE & BSI.

1.6 Materials used for cleaning procedures may be subject to COSHH regulations - manufacturer's

Instructions for Use must be followed at all times.

1.7 Materials used for maintenance and repair may be subject to COSHH regulations - manufacturer's

Instructions for Use must be followed at all times.

LFT5508 2.1 Issue 3

VIACLIN MODEL 2502 Oct 02

SECTION 2 - INTRODUCTION

2.1 GENERAL

The VIACLIN Alternating Pressure Mattress Overlay is designed for use whenever patients have some mobility problems

and/or who are vulnerable to pressure ulcer development and/or who have existing tissue damage. It gives gentle, dynamic

support to bedridden and immobile people in recumbent, supine and knee-break postures, providing alternatively support

then pressure relief to each part of the underside of the patient.

The bed can be repositioned whilst the Mattress Overlay is still inflated.

The system is suitable for use in hospitals, nursing homes and in the community.

2.2 SYSTEM DESCRIPTION

The system consists of a power unit and a mattress overlay. Audio and visual alarms activate if a fault condition exists for

more than three minutes (compressor failure, overlay or airpipe failure). An audio alarm sounds if the mains supply fails

(disconnected or switched off). These alarms alerts medical staff to the malfunction.

The specially constructed overlay comprises a series of pairs of transverse cells, which are inflated and deflated alternately.

Air to inflate the overlay is provided by an electronically controlled power unit. The air pressure in the overlay is

continuously monitored, and the system is completely self-regulating. The overlay is connected to the power unit by

means of an airpipe which features quick release connections at the power unit end, for convenience and rapid deflation,

to allow cardiac resuscitation procedures. Operator controls are purposely kept to a minimum.

The overlay is positioned on top of the normal bed mattress.

LFT5508 3.1Issue 3

VIACLIN MODEL 2502 Oct 02

SECTION 3 - SETTING UP/OPERATION

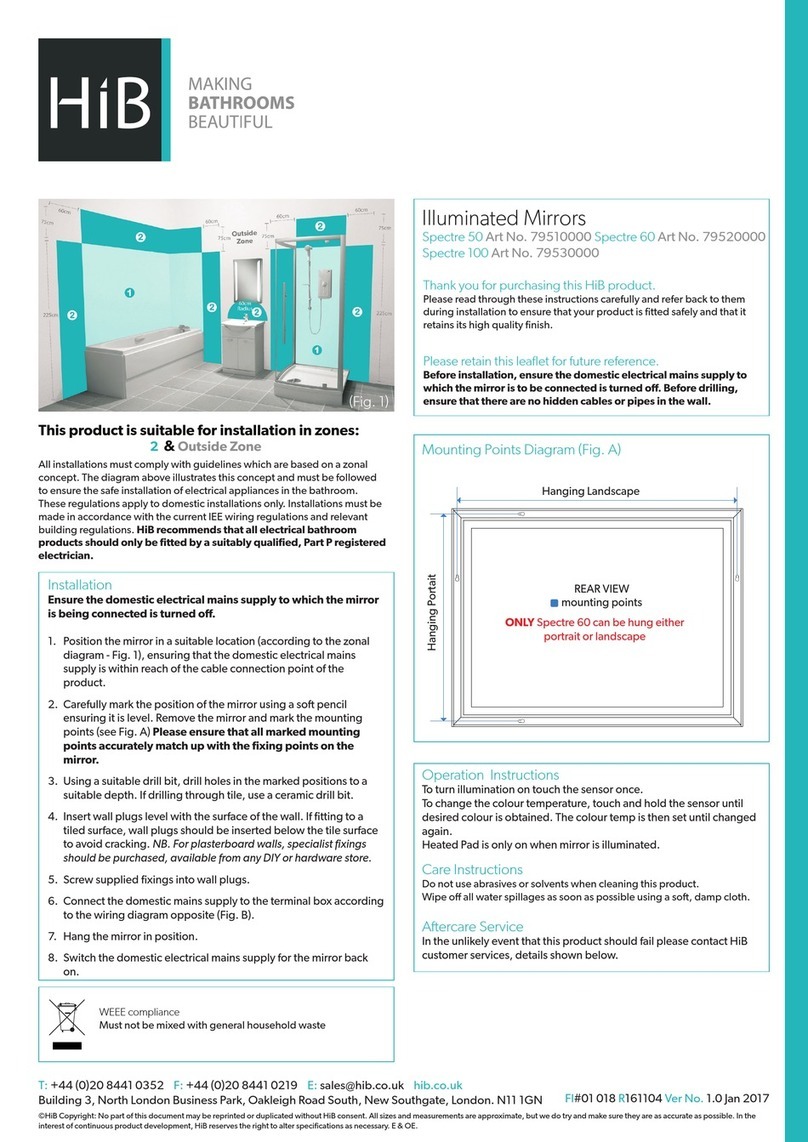

3.1 SETTING UP

CAUTION: Use only on top of the existing bed mattress.

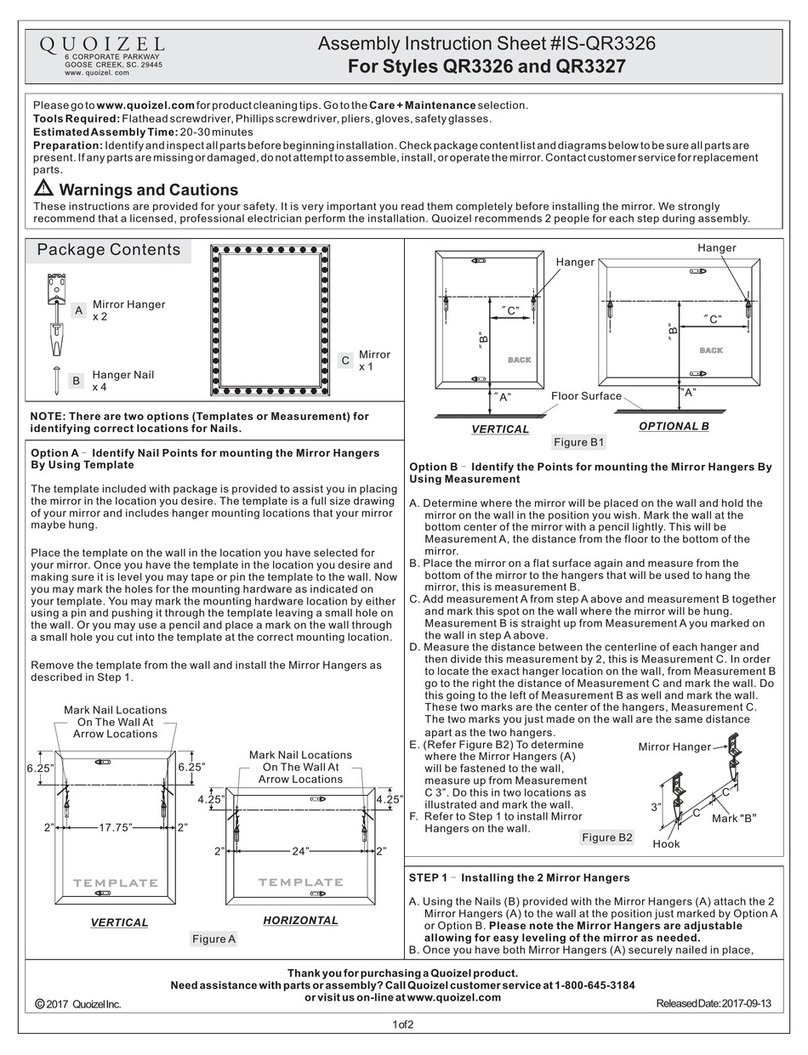

Remove the bedding from the bed.

Ensure there are no sharp objects to damage the Overlay. Place the Overlay on top of the bed mattress with the

umbilical at the foot end of the bed. Tuck the two end flaps under the bed mattress.

Secure the Overlay straps to the mattress. Do not secure to the bed frame (only secure Overlay straps loosely to the

moving parts of the bed frame, (if applicable).

LFT5508 3.2Issue 3

VIACLIN MODEL 2502 Oct 02

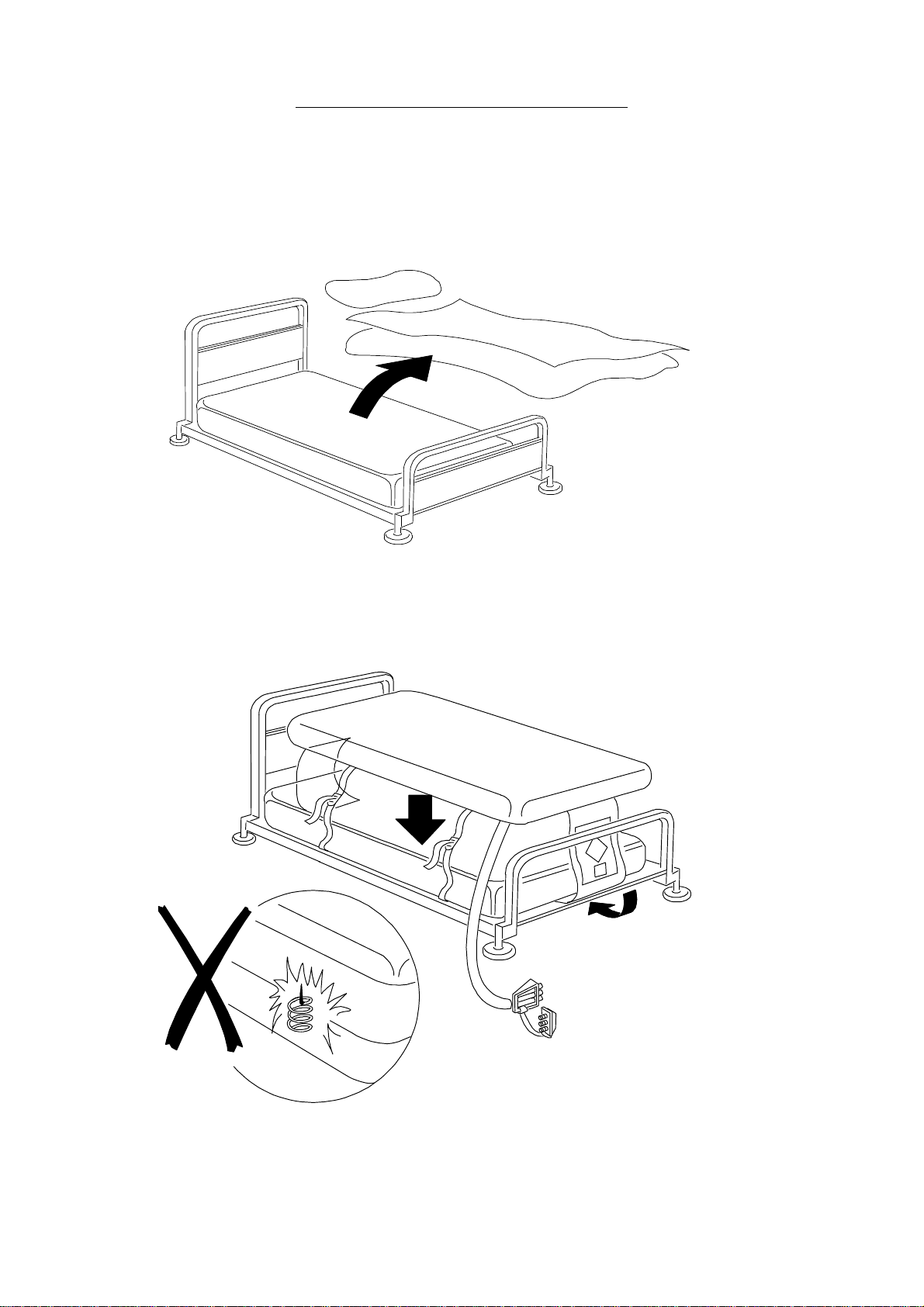

Hang the power unit on the bed or place on the floor.

Connect the three airpipe connectors on to the power unit connectors. Plug the power unit into a suitable mains

socket and switch on.

The system will take approximately 20 minutes to reach full inflation pressure, at which time the green NORMAL light

will come on and the amber light will extinguish. During this start up phase the red FAULT light may come on and the

audible alarm sound, if this occurs turn the power unit off and back on again to reset the alarm.

LFT5508 3.3Issue 3

VIACLIN MODEL 2502 Oct 02

Once inflated, check the securing straps and tighten if required. For maximum benefit, use only one sheet loosely

placed over the mattress. If the sheet is tucked in ensure that it is left loose over the mattress to avoid hammocking.

Once a patient is placed on the mattress the system will adjust automatically to the patient characteristics

(weight/position) to provide optimum clinical benefit for each patient. The mattress may feel firm at first until it has

adjusted to the individual. Allow approximately 15 minutes for this automatic adjustment to be completed.

If the mattress does not perform as described above, please refer to Section F of this guide ‘Alarms and Fault Finding’.

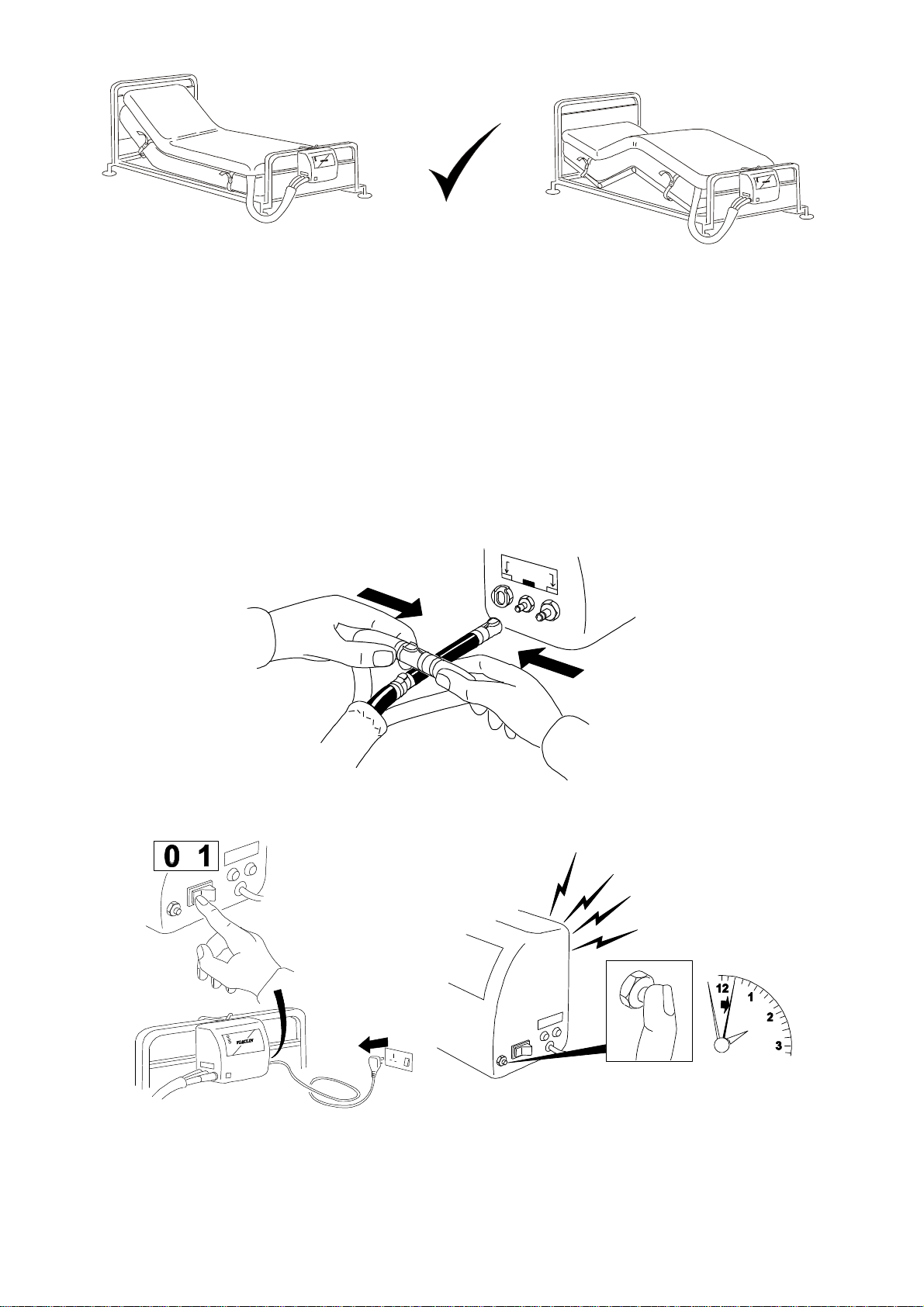

3.2 PROFILING AND KNEE-BREAKING

The system may be used while the bed is in the profiled or knee-break position:

1. With the bed in its present position, loosen or release the Overlay securing straps.

2. Change the bed to the required position (profile or knee-break).

3. Re-secure the securing straps.

NOTE: Straps must be attached to moving parts of the bed frame to avoid jamming the bed mechanism or stretching

the overlay.

12 111

10

9

8

7

2

3

4

5

6

Alternating Pressure Overlay

VIACLIN

!!ALARM!!

LFT5508 3.4Issue 3

VIACLIN MODEL 2502 Oct 02

3.3 MOVING THE BED AND POWER CUTS

CAUTION: The patient will not receive the benefit of the VIACLIN system while it is disconnected

and the power unit is switched off. Therefore the system should be reconnected as

soon as possible once the bed has been moved to its new position.

If you need to move the bed with the Mattress Overlay still inflated or in the event of a major mains power failure,

carry out the following procedure:

1. OVERLAY

aDisconnect the two red airpipes from the power unit and quickly connect together.

bDisconnect the black airpipe from the power unit.

2. POWER UNIT

aSwitch off and reset the power-down alarm. Disconnect from the mains.

b. The overlay will remain inflated for over 24 hours. The bed can now be moved.

LFT5508 3.5Issue 3

VIACLIN MODEL 2502 Oct 02

3.4 CPR (CARDIO PULMONARY RESUSCITATION)

In the event of cardiac arrest, disconnect both red airpipes:

1. While system is operating normally,

disconnect from the power unit.

2. While moving the bed, disconnect

from each other.

3.5 DEFLATION, REMOVAL, CARRYING AND STORAGE

POWER UNIT

1. Switch off.

2. Silence alarm.

3. Disconnect from mains.

4. Disconnect all airpipes.

5. Remove from bed.

OVERLAY

1. Undo all securing straps.

2. Roll up the Overlay.

This manual suits for next models

1

Table of contents