note:

• Pegler 66.7mm will be

referred to as 66.7mm

and/or 67mm

note:

• jaws for copper and steel dier at 108mm when pressing the sling

stays in place and a second pressing operation is required

4. Dri-Slide lubricant

Use of S135 Dri-Slide lubricant is essential when jointing large sized fittings. The pressing profile groove of the sling

jaws should be cleaned and lightly lubricated after every 50 joints for 42mm to 76.1mm sizes, and every 5 joints for

108mm. Dri-Slide should also be applied between the main sling arms and the moving segments; and along the pivot

pins between the arms. Wipe clean any excess lubricant so that it does not come into contact with the fitting “O” ring.

note:

• Dri-Slide lubricant should

never be used to

lubricate the “O” ring

When to lubricate

Size of fitting 42-76 108

Interval 50 joints 5 joints

5. press the joint:

Mount the jaws/sling jaws over the bead at the mouth of the fitting. With the tool fully supported and not hanging

from the pipework, and with your hands safely away from the joint, press the trigger or button to start the jointing

cycle. When the jaws/sling jaws fully enclose the mouth of the fitting, the joint is complete. The jaw should then be

released from around the fitting.

15 to 35mm Pegler recommend the use

of Sling Jaws for sizes 42 to

108mm

note:

• the 108mm joint is not fully made until the

fitting has been through two pressing

operations (Novopress only)

• maintain a 90° angle between the tube and

jaws at all times, this is to ensure the integrity

of the joint as well as protect the operator from

‘kickback’

• the pressing operation

should only be carried

out when the tube is

adequately supported

by brackets, not when

the tube is suspended

in the fitting socket

alone

• allow press-fit jaws

to be attached

without hindrance

• we recommend all systems are thoroughly pressure

tested before hand over to end user. Refer to

www.pegleryorkshire.co.uk for detailed

recommendations, particularly regarding Carbon Steel

installations

further details

Pegler Yorkshire Group Limited

St. Catherine’s avenue /Doncaster

South Yorkshire /DN4 8DF /England

tel: +44 (0) 800 1560 050

email: tech.help@pegleryorkshire.co.uk

www.pegleryorkshire.co.uk

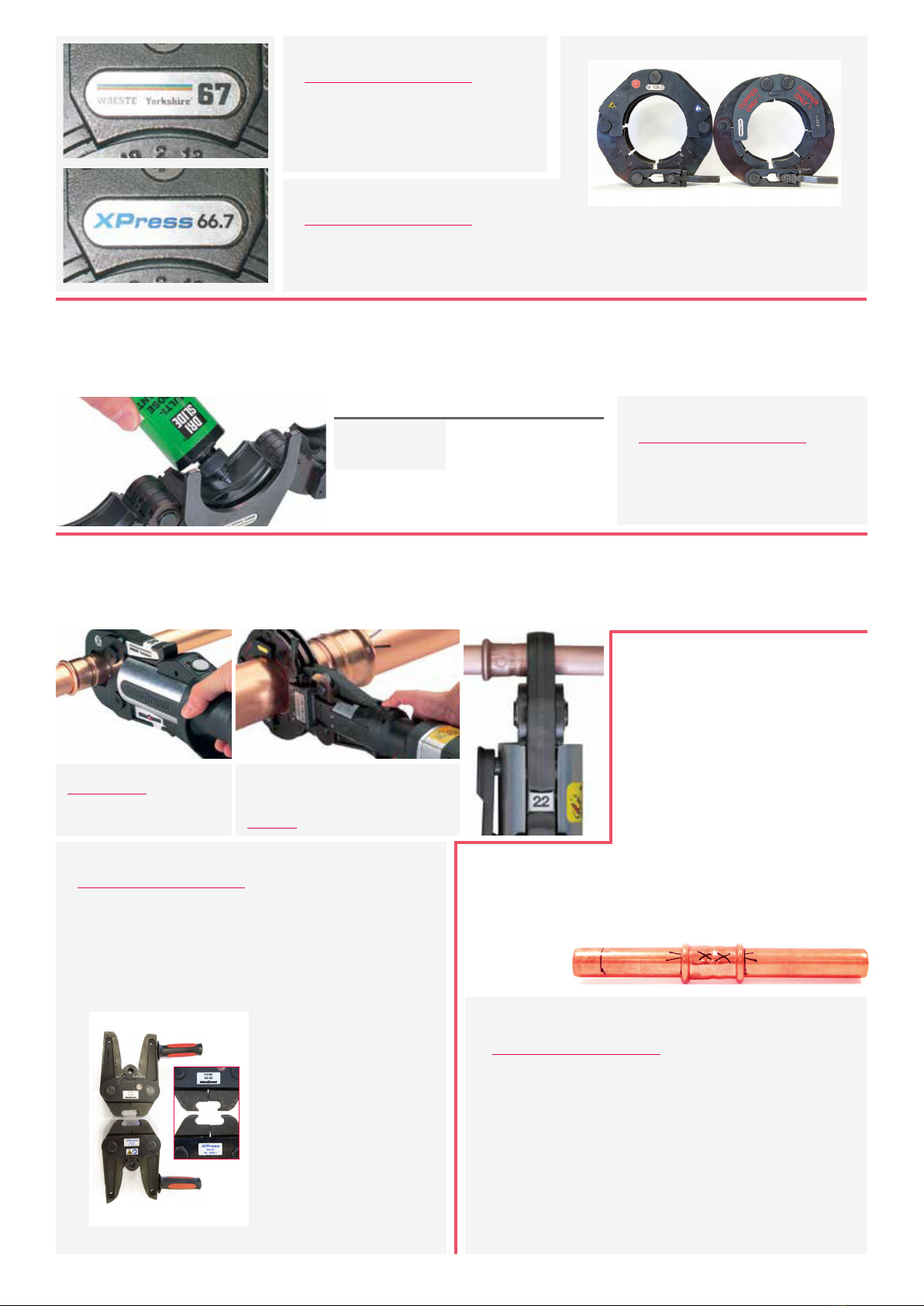

6. check the joint:

Inspect the finished joint making

sure all is in order, when satisfied

the joint has been made correctly

mark the joint as complete.

• the socket depth mark you made

indicates that full socket depth

has been maintained throughout

the pressing cycle

• the fitting and pipe bear the

witness marks from your

jaws/sling jaws