8

General Safety Instructions for power tools

Read all the safety notes, instructions, illustrations and technical data which come with

this power tool. Failure to heed the following instructions can lead to electric shock, re and/or

severe injuries.

Save all warnings and instructions for future reference.

The term “power tool” in the warnings refers to your mains-operated (corded) power tool or

battery-operated (cordless) power tool.

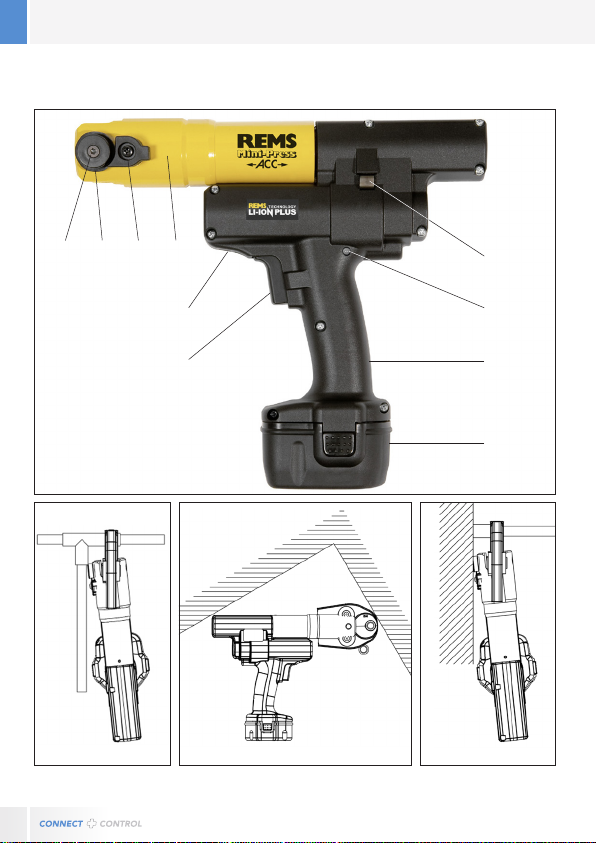

• Hold the power tool rmly by the housing grip (5) and pistol grip (9) and make sure you

are standing rmly when working. The power tool produces a very high pressing force. It is

safer to hold the tool with both hands. Therefore be very careful. Keep children and

bystanders away while operating the power tool.

• Do not reach into moving parts in the pressing area/expanding area. There is a risk of

injury by crushing ngers or hands.

• Never operate radial presses with the tongs retaining bolt unlocked (1). There is a risk of

fracture and ying parts can cause serious injuries.

• Always position the radial press with pressing tongs, Mini pressing tongs, pressing ring

with adapter tongs on the press tting at a right angle to the pipe axis. If the radial press

is positioned askew to the pipe axis, its high drive force will pull it to a right angle to the pipe

axis. This could crush hands or other parts of the body and/or there is a risk of fracture

whereby ying parts can cause serious injuries.

• Do not start radial presses without pressing tongs, Mini pressing tongs or pressing ring

with adapter tongs. Do not start the pressing process except to make a press joint. Unless

counter pressure is applied by the press tting, the drive unit, pressing tongs, Mini pressing

tongs, pressing ring and adapter tongs will be needlessly stressed.

• Before using pressing tongs, pressing rings with adapter tongs (pressing jaws, pressing

slings with adapter jaws) from other manufacturers, check whether these are suitable for

the REMS radial presses. Pressing tongs, pressing rings with adapter tongs of other makes

can be used in REMS Power-Press SE, REMS Power-Press, REMS Power-Press ACC, REMS

Akku-Press and REMS Akku-Press ACC if they are designed for the necessary thrust force

of 32 kN, t mechanically in the REMS drive unit, can be properly locked and break without

danger, e.g. without the risk of aying parts of the press jaws, at the end of their life or when

overloaded. It is recommended to only use pressing tongs and pressing rings with adapter

tongs which are designed with a safety factor ≥ 1.4 against permanent fracture, i.e. withstand

a necessary thrust force of 32 kN up to a thrust force of 45 kN. Also read and observe the

instruction manuals and safety instructions of the respective manufacturer/supplier of the

pressing tongs, pressing rings with adapter tongs and the installation and assembly

instructions of the manufacturer supplier of the press tting system to be pressed and

observe any restrictions for use that are specied there. Failure to do so could lead to fracture

and ying parts can cause serious injuries.