www.pelprostoves.com 7086-171D • July 10, 2014 3

TABLE OF CONTENTS

Safety Alert Key:

• DANGER! Indicates a hazardous situation which, if not avoided will result in death or serious injury.

• WARNING! Indicates a hazardous situation which, if not avoided could result in death or serious injury.

• CAUTION! Indicates a hazardous situation which, if not avoided, could result in minor or moderate injury.

• NOTICE: Indicates practices which may cause damage to the appliance or to property.

1 Listing and Code Approvals ............5

A. Appliance Certification......................................................5

B. Mobile Home Approved ....................................................5

C. Glass Specifications.........................................................5

D. Electrical Rating (On High)...............................................5

E. BTU & Efficiency Specifications........................................5

2 General Information..........................6

A. Fire Safety .........................................................................6

B. Non-Combustible Materials ...............................................6

C. Combustible Materials.......................................................6

D. Fuel Material and Fuel Storage........................................6

E. Before Your First Fire.......................................................6

3 General Operating Information.......7

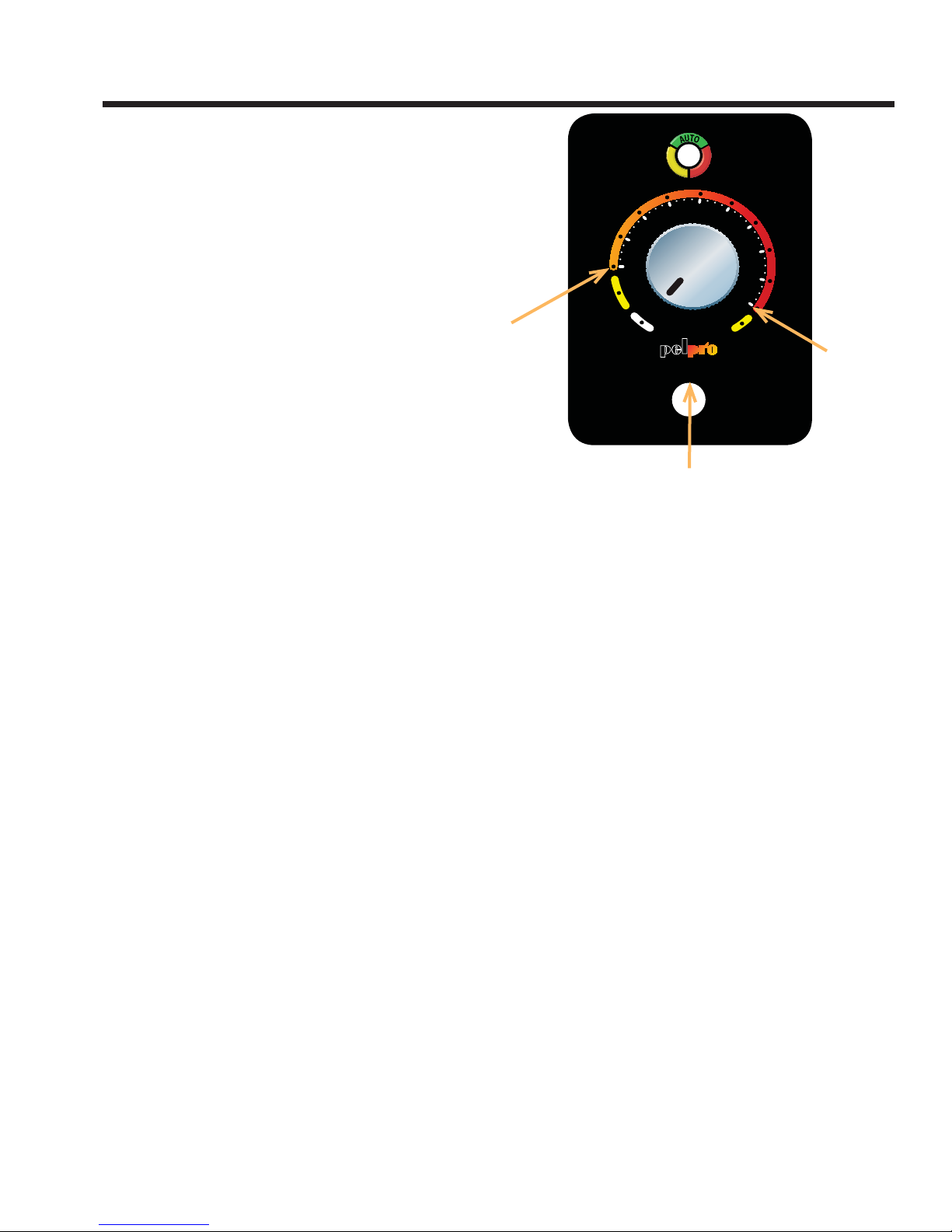

A. User Dial Control ...............................................................7

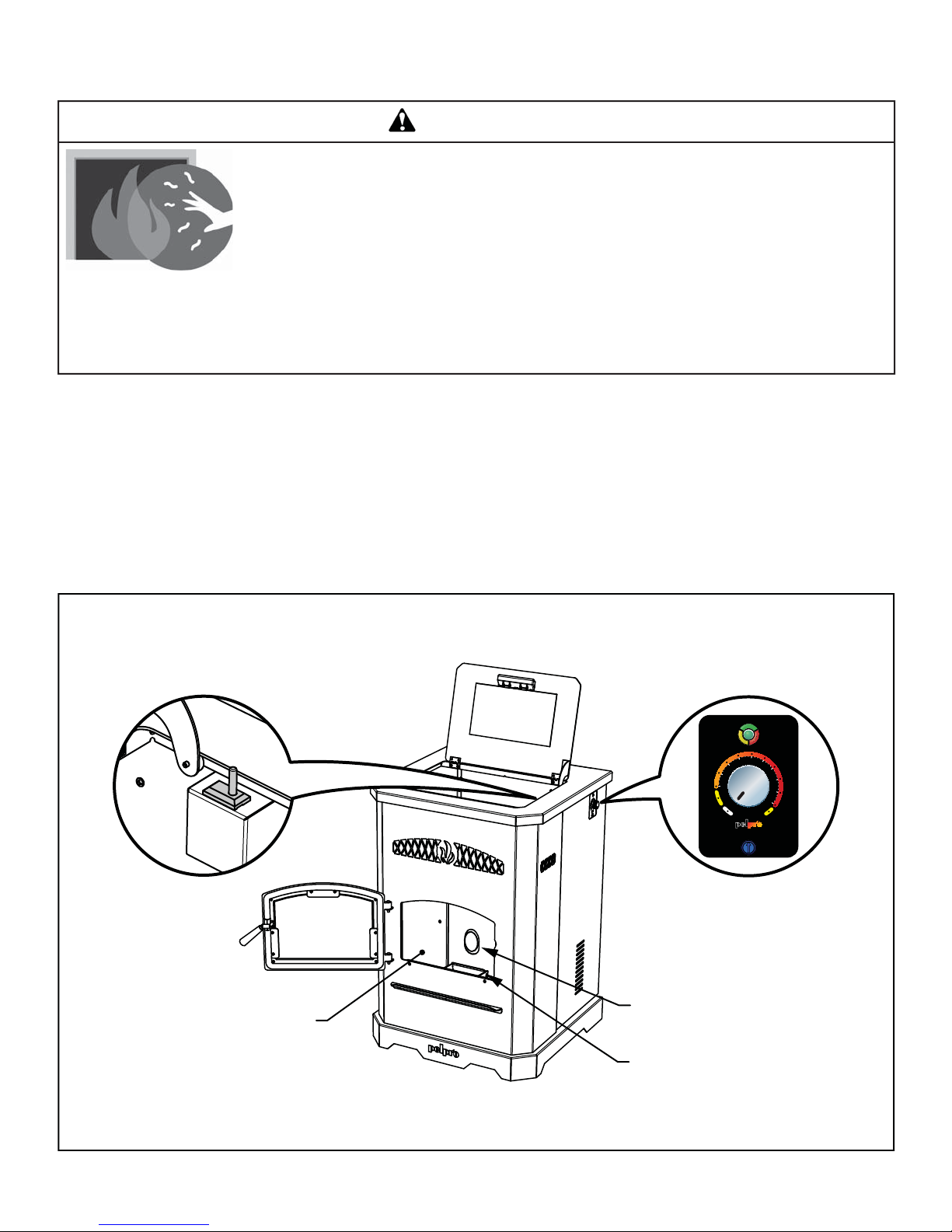

B. Filling the Hopper...............................................................7

C. Priming the Feed Tube......................................................7

D. Firepot Purge.....................................................................8

E. Shutdown...........................................................................8

F. Starting Your First Fire........................................................8

G. Fire Characteristics ...........................................................8

H. Your Pellet Appliance - General Operating Parts...............9

I. LED Color Coding Chart and Explanation..........................10

J. Ignition Cycles...................................................................11

K. Running in Minimum or Maximum....................................11

L. Running in the Comfort Level Mode..................................11

M. Clear Space .....................................................................11

N. Trim Adjustment................................................................11

4 Maintaining & Servicing

the Appliance....................................12

A. Proper Shutdown Procedure .............................................12

B. Quick Reference Maintenance Chart................................12

C. General Maintenance........................................................12

D. High Ash Fuel Content Maintenance.................................16

E. Frequently Asked Questions.............................................17

5 Replacement Parts............................18

A. Convection Blower Replacement ......................................18

B. Exhaust Blower Replacement............................................18

C. Snap Disc Replacement ...................................................19

D. Igniter Replacement ..........................................................19

E. Baffle Removal & Replacement ........................................19

F. Glass Replacement............................................................20

G. Feed Motor Replacement .................................................20

H. Feed Spring Replacement ................................................20

I. Control Board Replacement................................................20

J. Fuse Replacement.............................................................20

6 Getting Started..................................21

A.

Design, Installation & Location Considerations.........................21

B. Draft...................................................................................21

C. Negative Pressure.............................................................21

D. Locating Your Appliance & Chimney .................................22

E. Inspect Appliance & Components......................................22

F. ToolsAnd Supplies Needed ...............................................22

7 Dimensions and Clearances............23

A. Appliance Dimensions ......................................................23

B. Clearances to Combustibles (UL and ULC).......................23

C. Hearth Pad Requirements (UL and ULC)..........................24

8 Vent Information................................25

A. Chimney and Exhaust Connection...................................25

B. Venting Termination Requirements...................................25

C. Pellet Venting Charts.........................................................26

9 Venting Systems...............................27

A. Vertical - Interior - Typical Installation................................27

B. Through The Wall & Vertical - External - Horizontal ..........27

C. Vertical into Existing Class AChimney..............................27

D. Masonry............................................................................28

E. Alternate Masonry.............................................................28

F. Through The Wall..............................................................29

10 Mobile Home....................................30

A. Mobile Home Installation ...................................................30

11 Appliance Set-Up.............................31

A. Removal From Pallet.........................................................31

B. Outside Air Kit Instructions ................................................31

C. Power up the Unit .............................................................31

D. Hopper Extension (Optional Accessory)............................31

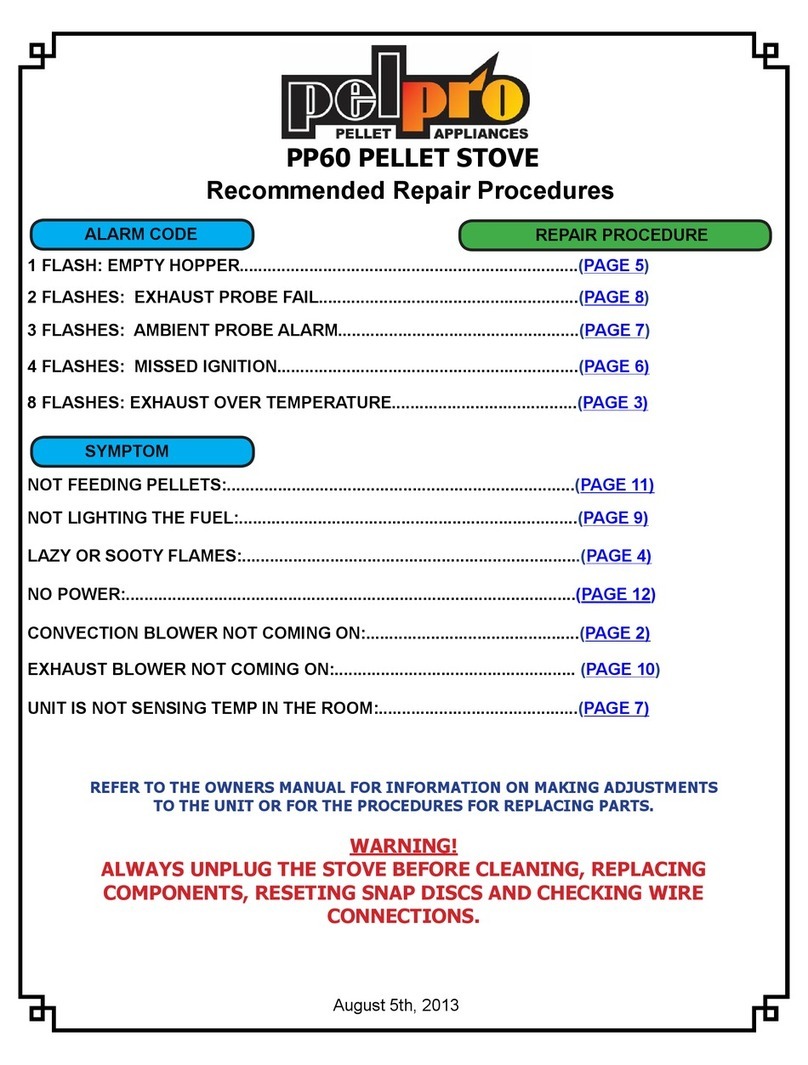

12 Troubleshooting..............................32

13 Reference Materials........................35

A. Component Function .........................................................35

B. Wiring Diagram..................................................................35

C. Replacement Parts............................................................36

D. Service & Maintenance Log...............................................38

E. Warranty ............................................................................39