3

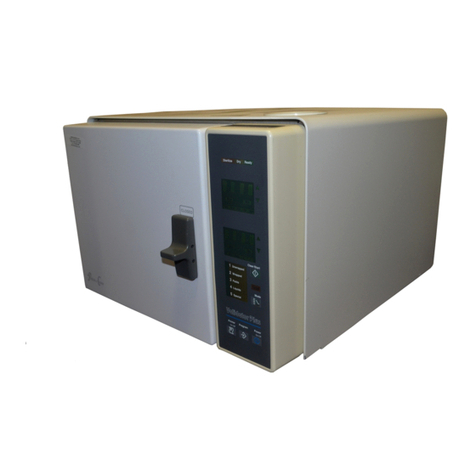

Model Designation: Solaris Sterilization Center Cabinet

Power Supply: SSC-120V/230V~50-60Hz,

15A Service (For each circuit)

Protection against harmful ingress penetration of water:

Ordinary Equipment

Technical Description

GENERAL INFORMATION

Definition of Symbols

WARNING: Only authorized service

technicians should attempt

to service this equipment.

Use of other than authorized

technicians will void the

warranty.

WARNING: This product must be

disinfected before use.

This product is intended for use by trained

dental/medical professionals only.

The following symbols may be used throughout

this manual:

Risk of electrical shockpresent.

Make sure power is disconnected before

attempting this procedure.

WARNING: Failure to carefully follow the

described procedure may result in damage

to the equipment and/or injury to the patient/

operator.

See operating instructions.

(AC) Alternating current.

Protective earth (Ground)

Manufacturing Date

Waste Electrical and Electronic Equipment.

Type B Applied part.

Indicates conformity to General Requirements for

Safety is certified by Intertek Testing Services.

General mandatory action required, important to

follow instruction. Not a caution.

Warning, strong magnetic field.

Off

On

Light Switch

Mode of operation: SSC-Continuous

Interference with Electromedical Devices

To guarantee the safety of electromedical devices, it

is recommended that the operation of mobile radio

telephones in the medical practice or hospital be

prohibited.

Strong EMI sources such as electro-surgery units or

x-ray units may affect performance. If performance

issues occur, move the unit to another electrical

circuit or physical location.

Product Disposal

Contact your local authorized dealer for proper

disposal of the device to ensure compliance with

your local environmental regulations.

Incompatible Units or Accessories

To guarantee the operational safety and function

of this device, the use of unapproved units or

accessories is not advised. Doing so could

result in potential hazard. Only use Pelton &

Crane approved accessories and devices.

1.013.2466 R00

Product Identification

This cabinet can be identified by its product

label, located inside the cabinet beneath the sink

on the left wall. This label states the cabinet model

and serial number, electrical specifications,

manufacture date and safety classification. Note the

SAMPLE label shown below.

ZachRules!

Manufacturing Place

DENTAL ___ __VAC__A__HZ

ETL CLASSIFIED