2

TABLE OF CONTENTS

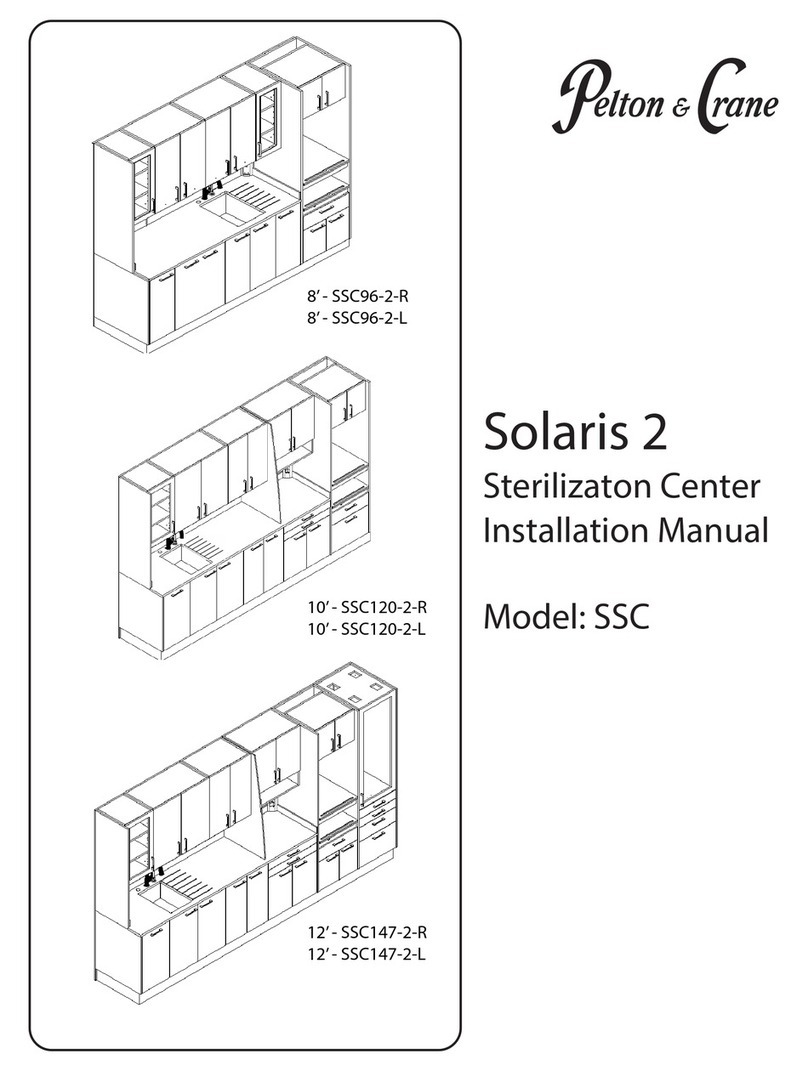

Visual Index .................................................................................................................................................... 3

Section I - Familiarization ................................................................................................................................... 4

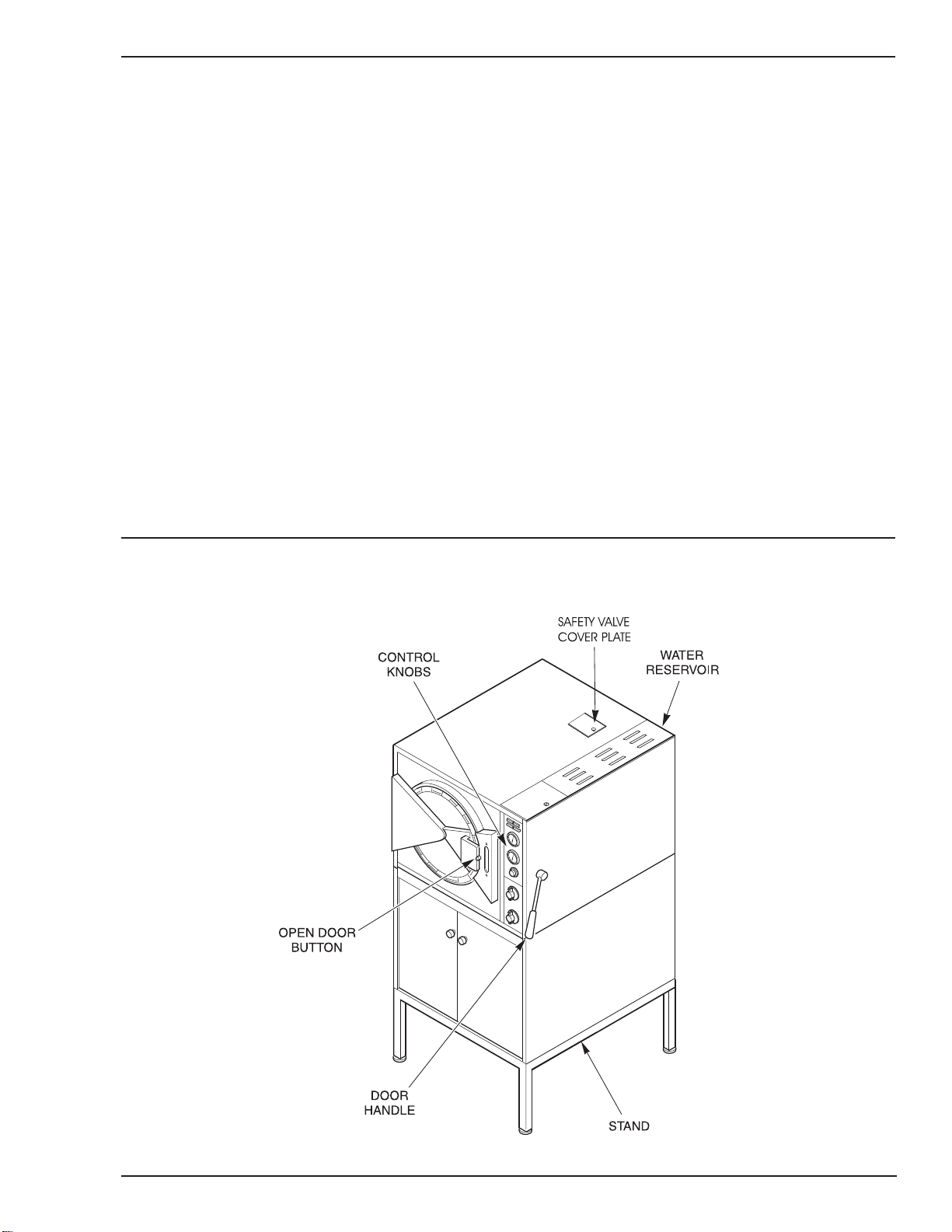

I. Safety Features ..................................................................................................................................... 4

A. DoorClampRing..................................................................................................................... 4

B. OpenDoorButton ................................................................................................................... 4

C. DoorHandle ............................................................................................................................ 4

D. RelayControl .......................................................................................................................... 4

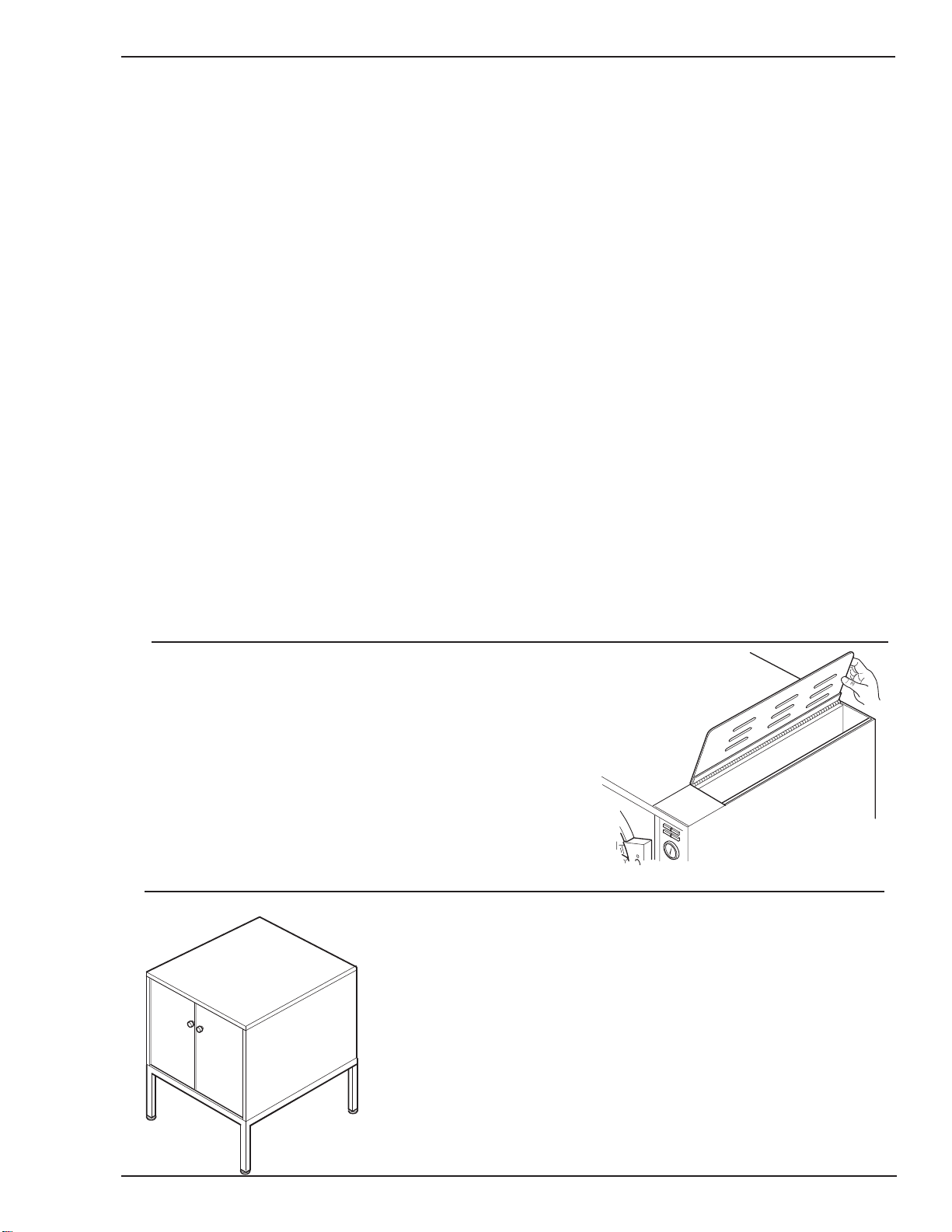

II. Physical Characteristics ....................................................................................................................... 5

A. Exterior ................................................................................................................................... 5

B. Interior .................................................................................................................................... 5

C. InstallationRequirements........................................................................................................ 5

III.Electrical Requirements ....................................................................................................................... 6

IV.Controlsand Indicators......................................................................................................................... 6

A. Indicator Lights ....................................................................................................................... 6

B. Gauges ................................................................................................................................... 6

C. ControlKnobs ......................................................................................................................... 7

D. Audible Signal ......................................................................................................................... 7

E. WaterReservoir....................................................................................................................... 7

F. Stand....................................................................................................................................... 7

Section 2 - Preparation for Sterilization ............................................................................................................. 8

I.Handlingand Cleaning of Instruments ....................................................................................................

8

A. Handling..................................................................................................................................

8

B. Cleaning.................................................................................................................................. 9

II.Preparation Guide for CarbonSteelInstruments.................................................................................... 9

A. Handling.................................................................................................................................. 9

B. Cleaning.................................................................................................................................. 9

C. SterilizationPreparation .......................................................................................................... 9

D. InstrumentWrapping ...............................................................................................................

9

III.TrayPreparation and Loading ............................................................................................................... 9

A. GeneralGuidelinesforTray Preparation................................................................................... 9

B. UnwrappedTrays ................................................................................................................... 10

C. WrappedTrays and Instruments ............................................................................................ 11

D. Packs.................................................................................................................................... 12

IV.LiquidsPreparation............................................................................................................................. 13

Section 3 - Operation ......................................................................................................................................... 15

I.General ................................................................................................................................................ 15

II.OperatingProcedures for Normal Sterilization ..................................................................................... 15

A.UnlockDoor ........................................................................................................................... 15

B. Fill.......................................................................................................................................... 15

C.Load....................................................................................................................................... 15

D.LockDoor............................................................................................................................... 16

E.SetTime Control .................................................................................................................... 16

F.SetTemperature...................................................................................................................... 16

G.Vent ....................................................................................................................................... 16

H.UnlockDoor ........................................................................................................................... 16

I.Drying...................................................................................................................................... 16

III.Operating Procedures for LiquidsSterilization .................................................................................... 17

A. PreparationandSterilization .................................................................................................17

B. Vent ...................................................................................................................................... 17

C. CoolDown ............................................................................................................................ 17

D. Unlock Door .......................................................................................................................... 17