3

When a Pendix eDrive has been installed into your bicycle, it

becomes a Pedelec. It is recommended to only retrofit bicy-

cles that comply with the known bicycle standards, such as

DIN EN14764, DIN EN14766 or ISO4210:2014.

1. Safety notes

In these instructions you will find four dierent symbols –

the symbol Note provides important information about

your new motor and how to use it, the symbol Caution

draws your attention to possible damage and/ or environ-

mental hazards, the symbol Danger warns you against

possible accidents and severe damage, including possible

injuries to your person. The symbol Torque marks sections

where a screw connection may only be tightened using a

torque wrench. The torque value given must be adhered

to. Whenever you see one of these symbols, there is a risk

that one of the hazards described may actually occur! Every

warning given is in a special box with a gray background for

emphasis.

Explanation of symbols

This symbol provides information about how

to handle the product or work with the respective

section in the system manual, which must first be

read through.

Caution: This symbol warns you against making

mistakes which can result in damage to material

or create an environmental hazard.

Danger: This symbol stands for a possible dan-

ger to your life and/ or health, if relevant instruc-

tions are ignored or not correctly followed. It also

draws your attention to the fact that correspond-

ing preventive measures must always be taken

beforehand.

Torque: Important screw connection! When

tightening up a threaded connection (screws),

the exact torque must be adhered to. The correct

tightening torque is either shown on the part in

question, or you will find it in the table of (torque)

tightening values on page 24 of this installation

manual. You must use a torque wrench to obtain

the proper torque. Parts which are not correctly

tightened can break or become loose! This can

cause severe falls and accidents!

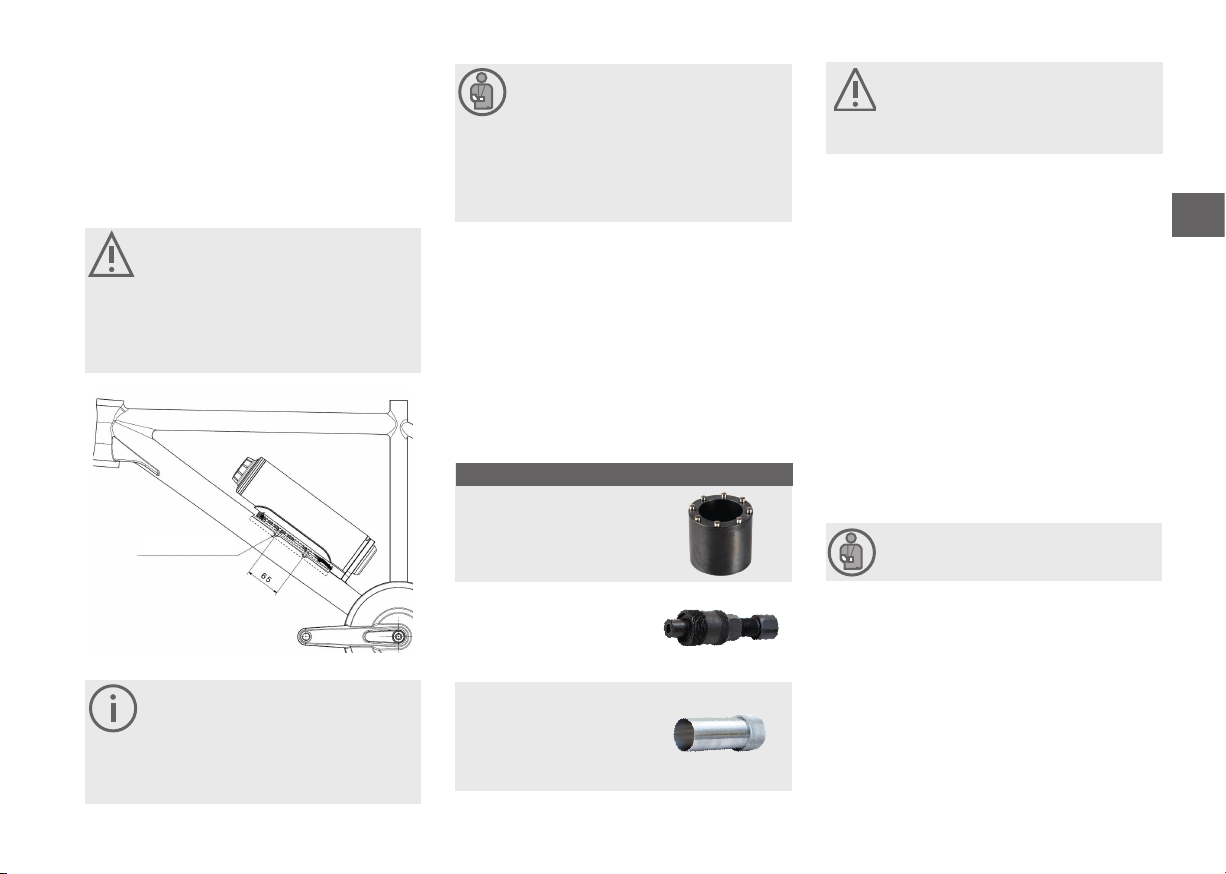

2. Introduction

This installation manual describes the installation of the

Pendix eDrive on a bicycle. It is meant for bicycle mechan-

ics, technicians and people with equivalent knowledge and

technological comprehension.

Carry out the assembly steps described in these

instructions only. No other steps may be under-

taken or changes made to the system. Do not

take apart or open components! Improper and

unprofessional mounting of the motor and ma-

nipulations to battery, charging unit and motor

involve great danger to health and damage of

material. In any such cases, Pendix refuses to

accept any responsibility for damage or acci-

dents caused.

For installation of the Pendix eDrive in a bicycle

or onto a bicycle frame, expert technical back-

ground and experience are required, as well as

special tools and equipment. For installation of

the Pendix eDrive in a bicycle or onto a bicycle

frame, expert technical background and experi-

ence are required, as well as special tools and

equipment. In general we would recommend to

choose an authorized Pendix premium partner

to do the installation.

Read the manual carefully and follow all instruc-

tions step by step. Pay special attention to the

Safety Notes. Always keep the installation man-

ual in a safe place, and pass them on to all other

persons working with a Pendix eDrive.

The Pendix eDrive is not designed for installa-

tion and eective use in bicycles for children

and juveniles up to the age of 14 years!

Make sure that the bicycle is in a technical per-

fect and non-damaged condition. Check all

components for cracks, breaks, deformations

or heavy wear. If you notice anything of this

kind, do not use the bike any further and let a

Pendix premium partner check and repair it, if

possible.

The Pendix eDrive motor is not designed for

use in areas subject to explosion hazard or

equivalent.

Please read all supplied instructions for safe

handling of the drive system and the bicycle.

The “Original Pedelec Operaing Instructions”

provides special instructions on handling and

maintaining the bicycle and also on existing

residual risks.

3. Field of application

The Pendix eDrive is provided for the following bicycle

types: City- / Trekking- / Touringbikes, Mountainbikes (Race/

Cross-Country), road bike, folding bike, recumbent bicycles

and further related types.

Because of the higher loads the application of

Pendix eDrive in downhill-, freeride-, BMX-cycles,

dirtbikes and further related types as well as op-

eration in competition is prohibited. The usage

in static conditions (dyno, home gym) is also

prohibited.

Using clipless pedals in combination with Pendix

eDrive is prohibited.