8 THREE: COMPLETE

COMPLETE

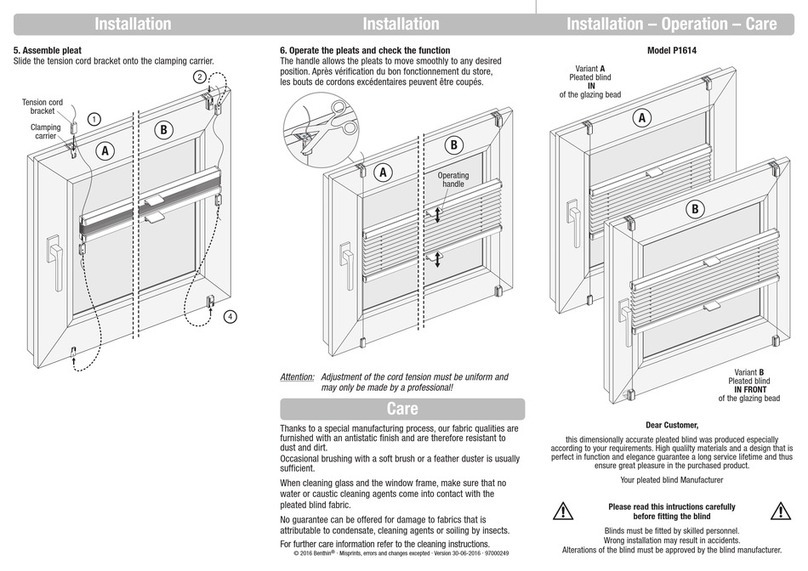

1. Replace the box housing (A) cover lid

and secure it with the two screws you

removed in stage 1 of the installation.

2. Using your tester cable, test the

operation of the screen. Operate it

down and then up to ensure the screen

is installed correctly and the curtain

runs smoothly.

The motor limits are not set yet, so the

curtain will not stop automatically at

the top and bottom, and you may need

to hold the button controls down when

operating, as it will not run by itself

until you set the limits. See step 4 for

the limit setting instructions.

3. If your screen is installed outdoors:

The screen frame must be sealed to

the wall. Put a good bead of suitable

exterior caulking where the screen

frame meets the wall along the top and

on both sides of the screen frame.

4. Refer to the limit setting and

programming instructions provided for

setting the open and closed stop limits

on your screen.

5. The screen should be connected

to the power supply by a qualified

electritian. Please give the installations

instructions and wiring diagrams

provided with the screen to the

electrician.

3

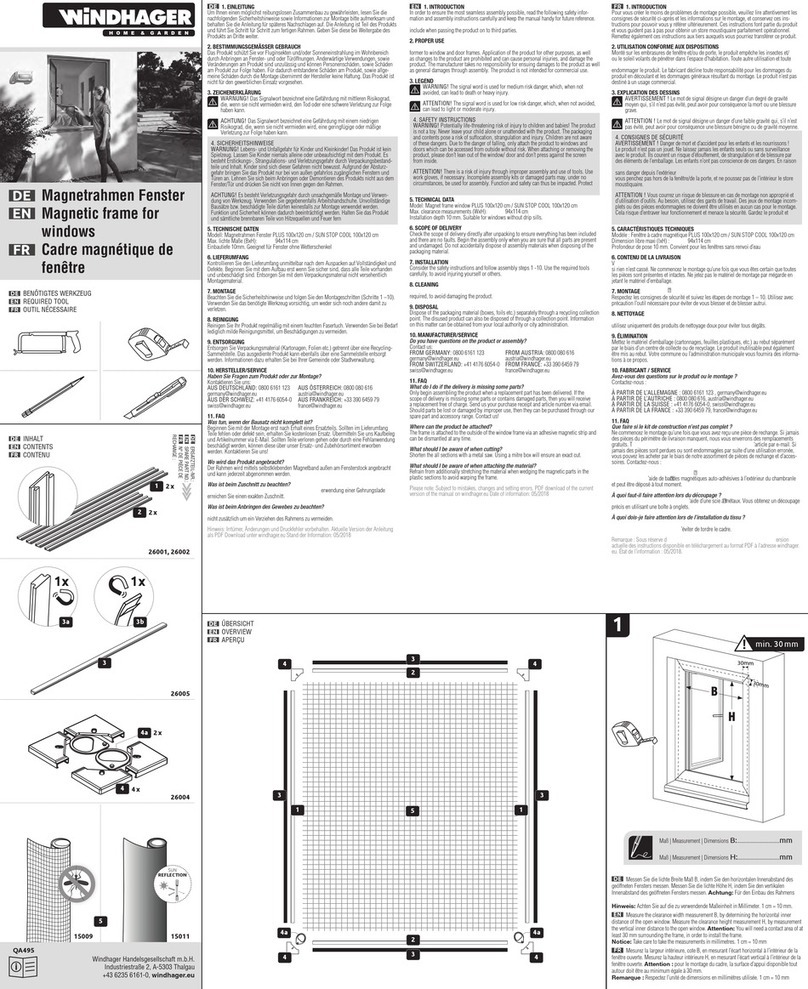

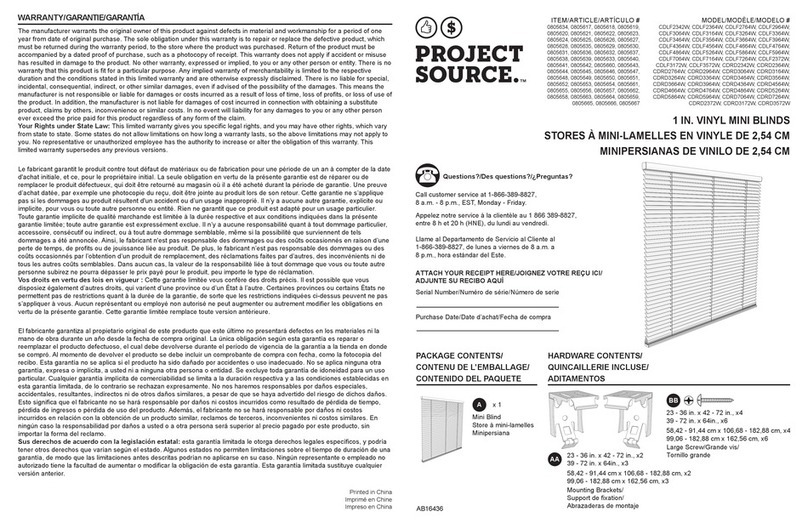

Match the colors of the wires with the

corresponding colors on your tester

cable clips. If the screen operates in

the opposite direction to your tester

cable switch, swap the black and red

wires.

Red

Red

White

White

Black

Black

Green

Green