WeatherMaster Eclipse Shutters User manual

Other WeatherMaster Window Blind manuals

Popular Window Blind manuals by other brands

weinor

weinor VertiTex ZipR Maintenance Instructions and Directions for use for the end user

Roto

Roto ZAR M R4/R7 Mounting instructions

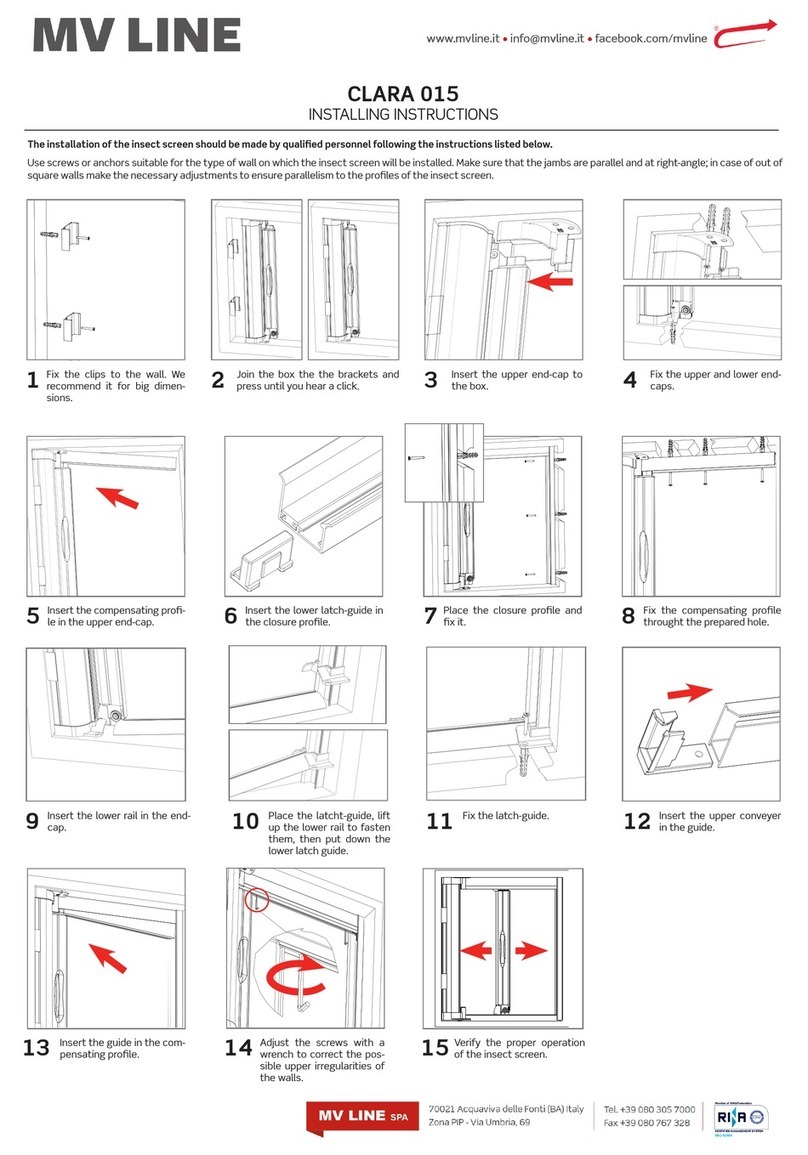

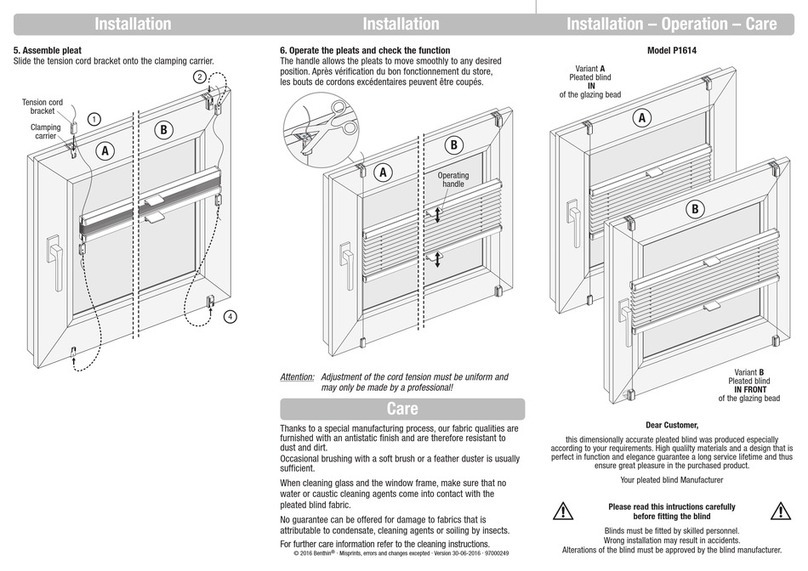

Benthin

Benthin P1614 quick start guide

MDT

MDT KNX Smart 55 BE-JTA5504.01 Technical manual

Victoria M

Victoria M SYSTEM VS 1 Original instructions

SOMFY

SOMFY Movelite WT Series instructions