460i/460TC Control System

Operation and Maintenance Manual

1017948 Rev E FE11

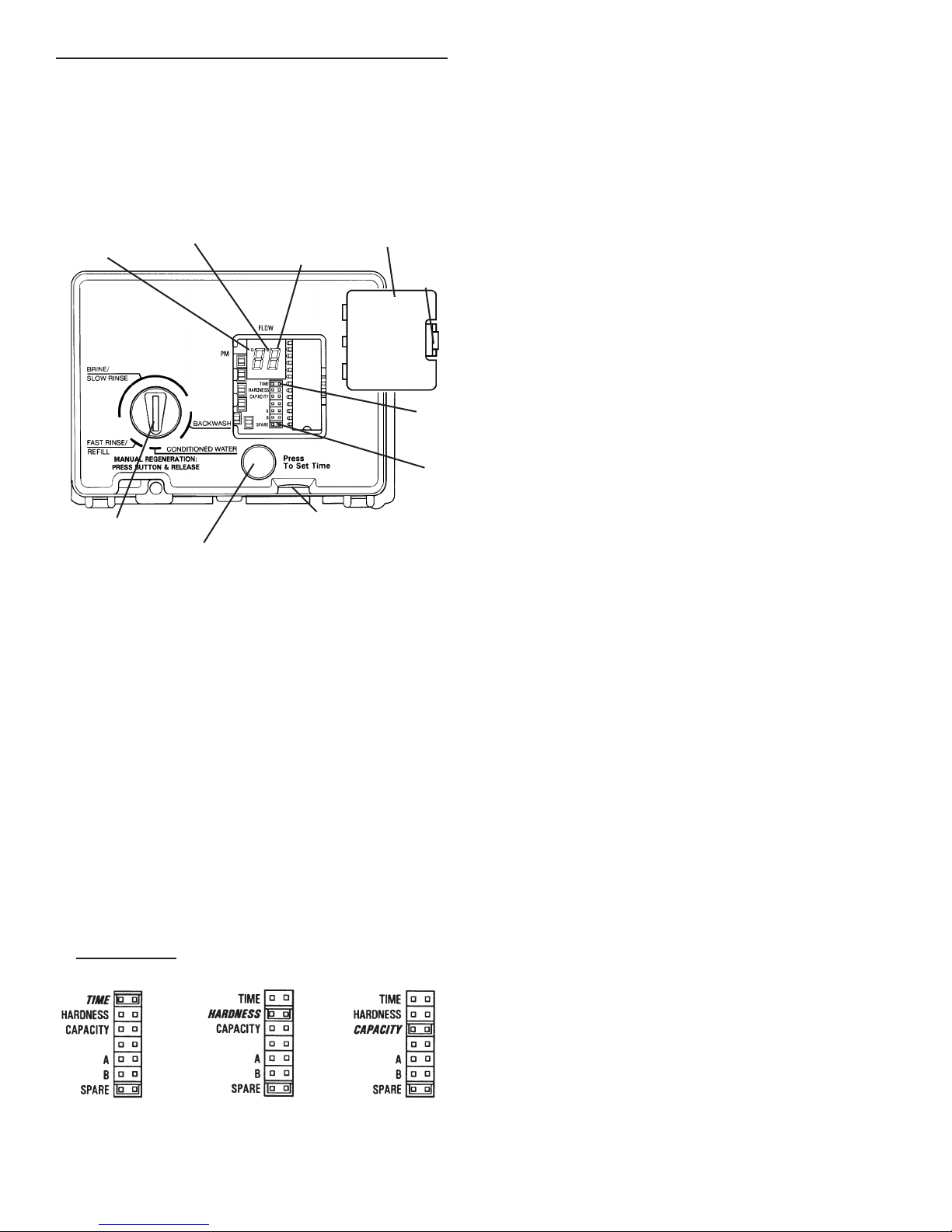

460i ELECTRONIC DEMAND SYSTEM

The 460i electronic demand system is available as an option

on automatic controls for water conditioning equipment.

Retrotting of existing water treatment installations is easily

accomplished, and the cost is amortized over a short period of

time by the home owner in salt and water savings.

The two key components of the 460i electronic demand system

are the microprocessor, a miniature computer located on the

circuit board, and a water meter located at the valve outlet.

The ow of conditioned water through the meter generates

electrical impulses that tell the computer the amount of water

being used.

Every day, at 2:00 a.m., the past seven days’ water usage is

statistically averaged to anticipate the amount of water to be

used the next day. The computer then determines if the water

conditioner has enough remaining capacity to supply the next

day’s needs. If not, the unit will regenerate.

If the water usage pattern changes, the computer automatically

compensates for the change and regenerates only when

needed. This results in higher operating efciency and lower

salt usage than a conventional conditioner operating on a xed

regeneration schedule.

SPECIAL FEATURES 460i

Memory Retention

During a power outage, all of the data in the microprocessor’s

memory is stored in a special electronic chip called NOVRAM,

Nonvolatile Random Access Memory. This data includes the

time of day, water usage amounts, and the number of days

since the last regeneration. The NOVRAM will maintain the

data in its memory. When power is restored, the NOVRAM

returns the data to the microprocessor and operation resumes

as if an outage never occurred.

The time of day will be late by the length of the power

outage. Most power outages are less than one minute in

duration. Therefore, it may be months or years before the

time display would require resetting. If an outage of one or

more hours occurs, the time of day should be reset. No other

reprogramming is necessary.

Self-Adjusting Reserve

“Reserve” refers to the amount of soft water that may be

needed for the next 24 hours. The microprocessor calculates

how much soft water was used and adjusts the reserve

capacity accordingly at the end of each day. As a result, the

reserve is kept at a minimum for optimum economy. The

reserve amount is calculated by multiplying the average past

seven days’ usage by 1.20. Regeneration decisions are based

on the calculated reserve.

In the event of unusually high water usage (twice or more than

the current daily average), the high usage amount will be used

as the reserve when the computer performs its regeneration

computation at 2:00 a.m. This is done in anticipation of a

second day of very high usage.

High Water Usage

The 460i is programmed to react to a sudden increase in

water usage. If a day’s usage is more than double the current

average, the computer anticipates that a second day of

high usage is likely to occur. The high usage amount will be

used as the reserve when the 460i performs its regeneration

computation.

Low or No Water Usage

The 460i is programmed to recognize a day of very little or no

water usage as an abnormality. It will not use data from such a

day to compute the average usage. For example, if the family

is on vacation for a week, the prior average will be maintained.

When household activity resumes, the 460i will operate as if

the vacation had not occurred.

Design Reliability

Solid-state electronics assure many years of trouble-free

performance. And, the metering system has only one moving

part, that is the rotating turbine that measures water usage and

creates magnetic pulses that are continually counted by the

microprocessor to determine the need to regenerate.