5

MY880 (03-01-21)

PUMP SERVICING

Servicing should be performed only by knowledgeable pump

service contractors or authorized service stations.

1. Remove pump from sump. Before removing pump from

sump pit for repair, check if the trouble could simply be

a blown fuse, tripped circuit breaker, or a power cord not

completely inserted into the receptacle.

2. Check diaphragm switch. If the unit is being operated by

the automatic diaphragm switch, unplug the pump from

the piggyback receptacle and plug the pump directly

into the power source. If the pump starts each time it is

plugged directly into the receptacle and does not start

each time when plugged into the piggyback switch with

the diaphragm switch pressed into a start position,

replace the complete piggyback switch assembly and

retest with new assembly.

3. Check for impeller blockage. Disconnect pump and

switch from power source. Check for an obstruction in

the impeller cavity by laying the pump on its side and

inserting a screwdriver into impeller. Impeller should turn

freely. If impeller is stuck, then turn the pump on its side,

DRAIN THE OIL through the oil fill plug on top of the pump.

Drain oil into a clean, dry container. A milky appearance

to the oil indicates that water has entered through either

worn out or damaged seals (7) or seal ring. Remove the 4

screws (6) to remove the volute (9). If the impeller (10) does

not rotate freely, clear the impeller and cavity walls before

reassembling the base. Repeat Step 2.

4. Check power cord. If the above tests have not resolved

the problem, it may be in the electrical components of the

pump. Starting with the power cord (2), inspect for cuts or

nicks in the insulation. If the cord is damaged – replace it!

5. Remove the motor cover. Use a screwdriver to pry the

motor cover (3) from the seal plate (8) at the fastening ears,

being careful not to cut the seal ring with the screwdriver

or crack the motor cover. Lift the motor cover until it

clears the stator (4).

6. Check for short. Disconnect the stator leads from the

connector. Use an ohmmeter to check the continuity of

the stator. If stator fails to pass the continuity test, it must

be replaced.

Ground check. Set ohmmeter scale pointer to R X 100K

scale and check meter by putting both meter leads

together and adjusting the needle knob until meter

reads zero. If meter cannot be adjusted to zero it will

indicate that batteries in meter must be replaced.

Always make this test with the meter when scale pointer is

set to a new scale before making any checks on motor.

Now connect one meter lead to one blade terminal of

stator and touch other meter lead to motor stator shell

(4). If needle reads below 5 (500,000 ohms) stator must

be dried out before reusing. To dry out, bake in 220° oven

for 4 hours. Recheck after motor cools. If motor is new or

thoroughly dry, needle of ohmmeter will not move on the

ground test. This indicates a reading of 50 megohms or

higher. One megohm is one million ohms.

When making the ground test, if the needle goes clear to

zero the motor probably has a wire touching the stator at

some point and the stator will have to be replaced.

Winding resistance test. If motor shows a satisfactory

ground test, then the winding resistance must be

checked. Use ohmmeter with scale pointer set on R X 1

scale. On this scale meter reads directly on ohms. Always

check the meter with leads together as described above

under ground test before making a reading of the winding.

Connect one meter lead to each of the black terminal

leads. Meter should read about 1.35 ohms. This is the

resistance of the main winding for a 115 volt stator. This

reading for a 230 volt stator should be about 6.22 ohms.

Now remove the capacitor and connect one meter lead to

each of the brown wire terminals. The meter should read

about 11.35 ohms for a 115 volt stator. For a 230 volt stator

this reading should be 32.4 ohms. This is the resistance of

the start winding.

7. Remove the stator. To remove the stator, remove the four

hex head screws and disconnect the brown capacitor

leads from the capacitor and remove the stator plate with

the capacitor. Lift the stator off the seal plate (8) and set

aside.

8. Remove the impeller. To remove the impeller (10), hold

the motorshaft (5) with a screwdriver at the center of

the impeller and tap the impeller with a plastic or rubber

mallet so as to turn the impeller counterclockwise.

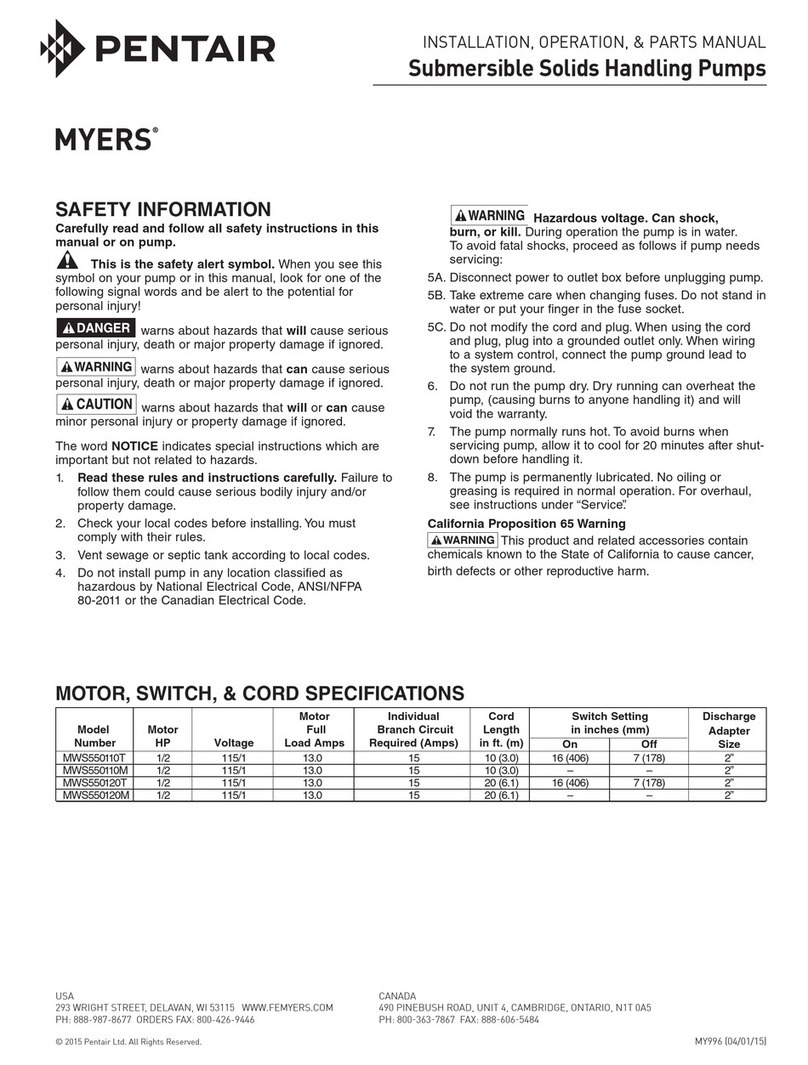

MAINTENANCE AND SERVICE

CAPACITY GALLONS PER MINUTE

TOTAL HEAD IN METERS

TOTAL HEAD IN FEET

CAPACITY LITERS PER MINUTE

40

30

20

10

0

0 180150120906030

MSKV50