3

INSTALLATION

Installation and wiring of pump should only be done by

qualified, licensed personnel.

Pump mount must:

Be Solid - Level - Rigid - Vibration free. (To reduce vibra-

tion and pipe stress, bolt pump to mount.)

Be installed with pump suction inlet below water level at

all times (this allows pump to prime).

Be installed with pump discharge below water level at all

times (to avoid trapped air in discharge line).

Allow discharge line to be level or slope slightly up to

heater, spa, or pool.

Have adequate drainage to prevent flooding.

Be protected from excess moisture.

Allow adequate access for servicing pump and piping.

Ventilation:

Provide adequate ventilation to prevent motor overheat-

ing.

For continuous running, motor hot air exhaust must be

able to escape motor compartment.

Piping:

Use flexible or rigid PVC pipe for connections to pump.

Suction/discharge piping gate valves will allow removal

for servicing.

Use at least 1-1/2" IPS pipe.

Fittings restrict flow; for best efficiency use fewest possi-

ble fittings.

Pump will not prime if suction pipe leaks.

Unions are provided. Use as follows for leak-free connec-

tions to pump:

1. ‘O’ Ring and sealing surfaces must be clean.

2. Assemble handtight only! (NO WRENCHES!)

3. NO pipe compound or Teflon tape on unions.

4. Bond pipe to unions with PVC cement.

Use PVC cement only in a well ventilated

area away from flame; FOLLOW MANUFACTURER‘S

INSTRUCTIONS!

Spa Fittings:

Size and number of jets will have a major effect on jet

action.

Typical installations use up to four 7/8" or 3/4" diameter

jets or up to seven 1/2" diameter jets.

Spa fittings must meet International Association of

Plumbing and Mechanical Officials (IAPMO) standards.

Use only non-entrapping suction fittings or

double suction.

ELECTRICAL

Hazardous voltage. Can shock, burn,or

cause death. Ground pump before connecting to power

supply.

Ground motor before connecting to electrical

power supply! Failure to ground pump motor can

cause serious or fatal electrical shock hazard!

Do not ground to a gas supply line!

To avoid dangerous or fatal electrical shock, turn

OFF power to motor before working on electrical

connections.

GFCI tripping indicates an electrical problem. If

GFCI trips and will not reset, have a qualified elec-

trician inspect and repair electrical system.

Exactly match supply voltage to nameplate voltage

(110 Volt or 220 Volt 50 Hz single phase only)!

Incorrect voltage can cause fire or seriously damage

motor and voids warranty!

Grounding:

Install, ground, and wire motor according to local code

requirements.

Permanently ground motor; use size and type wire re-

quired by code.

Ground connection must be made to green grounding

terminal.

Connect motor ground terminal to electrical service

ground.

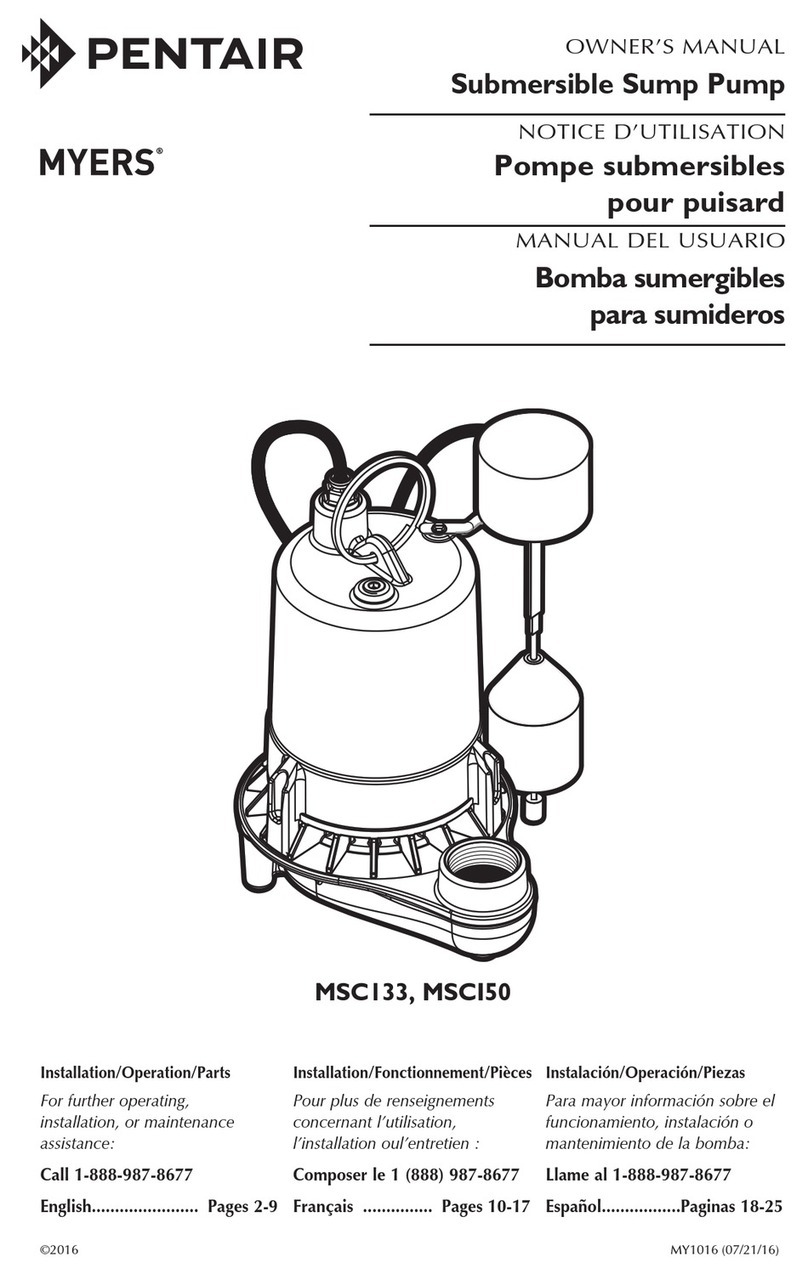

Install and bond pump according to local codes and ordi-

nances; use bonding lug on motor (see Figure 1). Use

solid copper conductor 8.4mm2or larger.