3

VisuNet GXP

Contents

2020-04

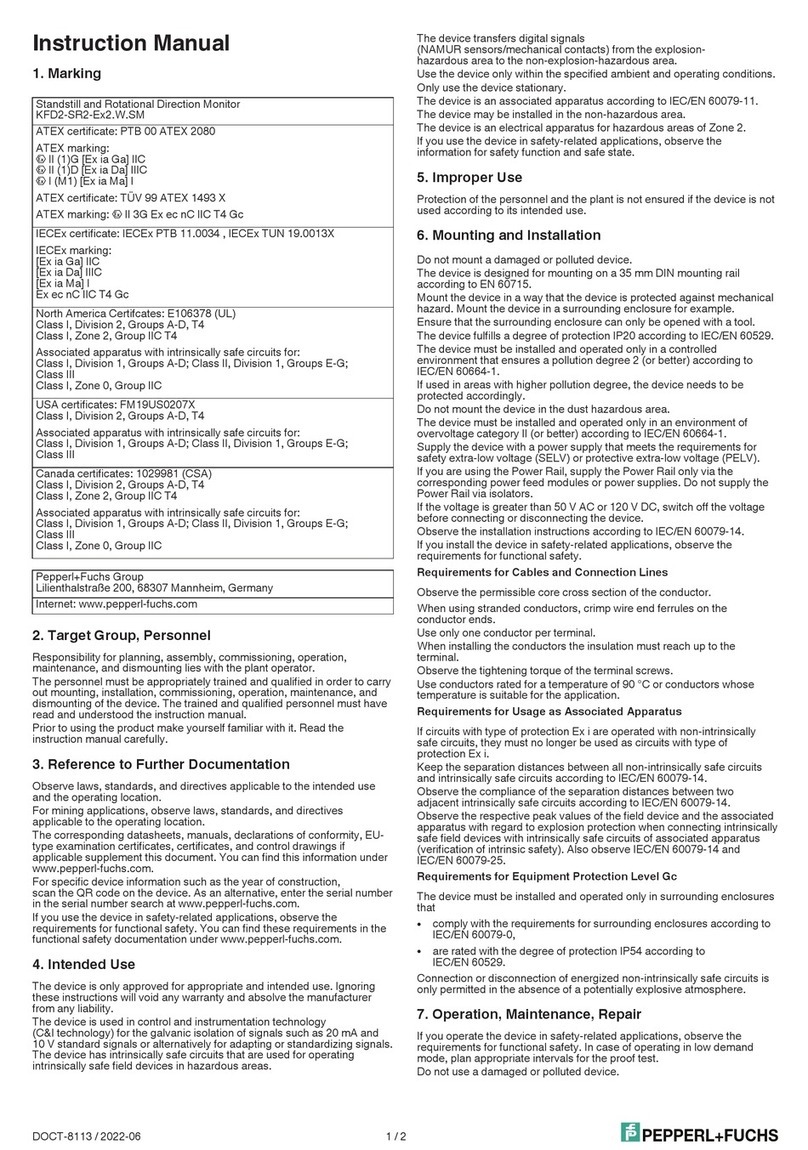

1 Introdu tion................................................................................................................ 4

1.1 Content of this Do ument............................................................................. 4

1.2 Target Group, Personnel ............................................................................... 4

1.3 Symbols Used ................................................................................................ 5

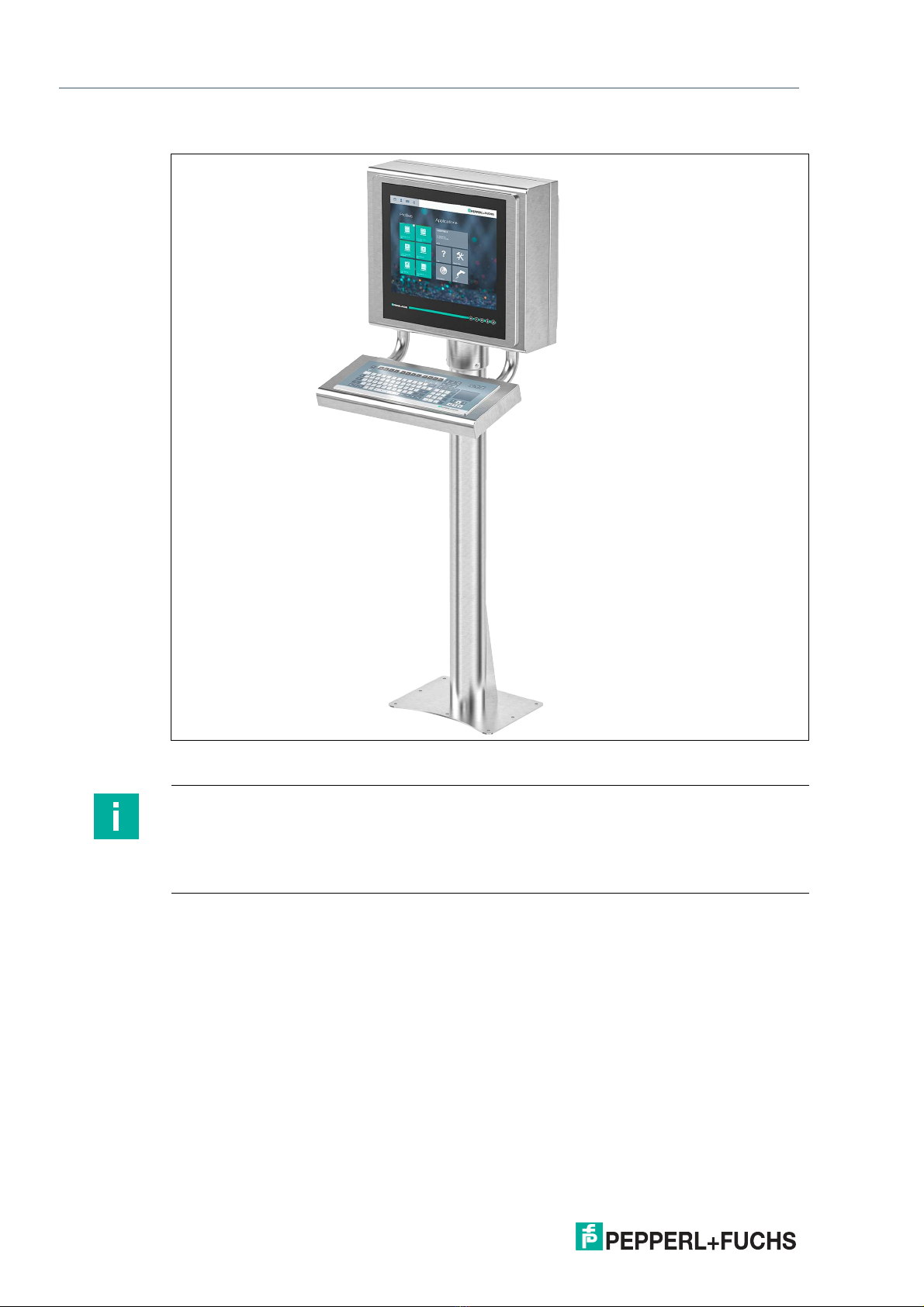

2 Produ t Des ription .................................................................................................. 6

2.1 Overview......................................................................................................... 6

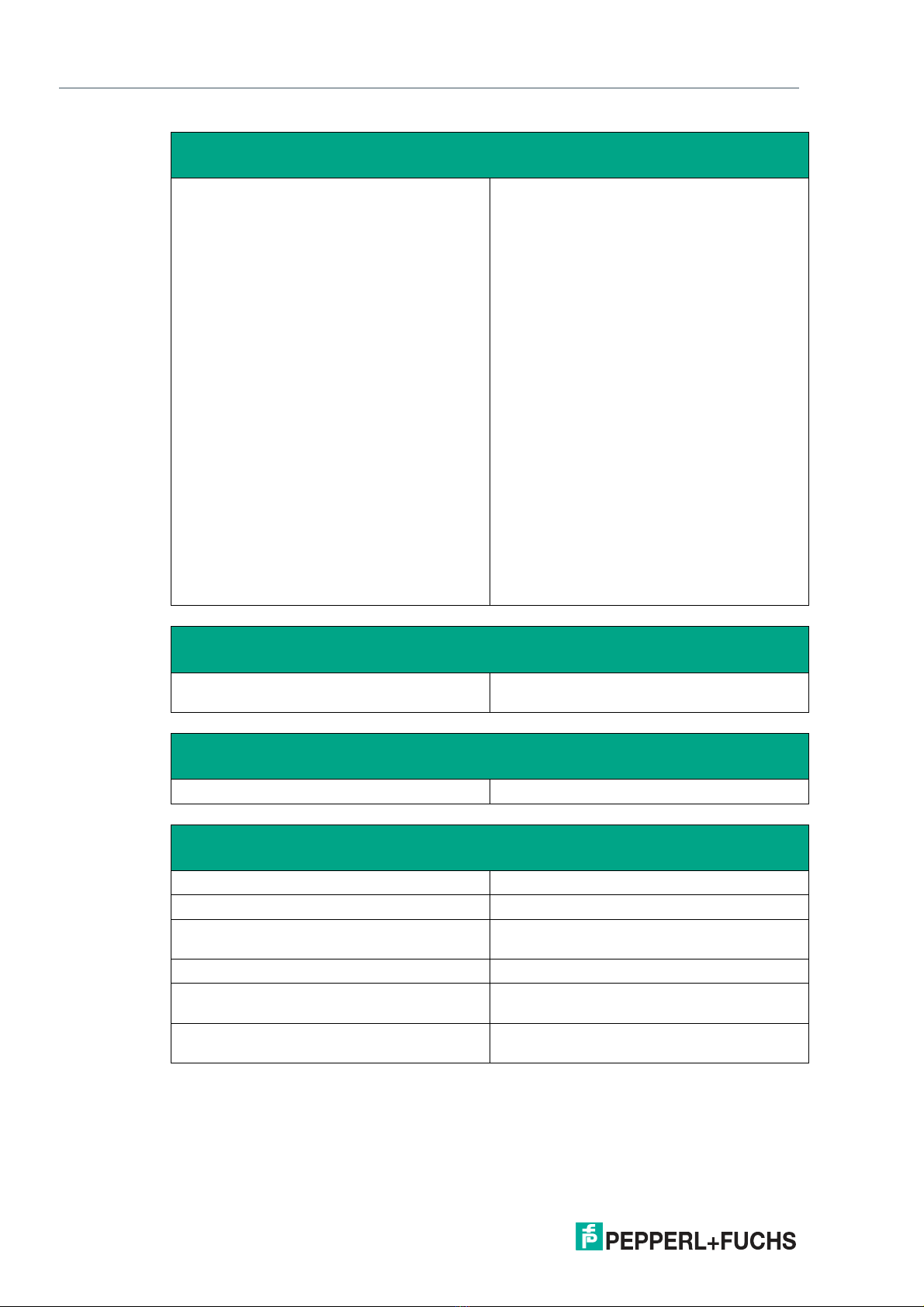

2.2 Te hni al Spe ifi ations ............................................................................... 9

2.3 Dimensions................................................................................................... 12

2.4 Disposal........................................................................................................ 14

3 Me hani al Installation ........................................................................................... 15

3.1 General Installation Requirements ............................................................ 15

3.2 Installation Tools.......................................................................................... 15

3.3 System Installation ...................................................................................... 16

3.3.1 Preparation for System nstallation................................................... 16

3.3.2 Preparing the GXP Panel/Housing ................................................... 17

3.3.3 Preparing the StandardLine Pedestal .............................................. 20

3.3.4 Attaching the Pedestal to the Housing ............................................. 24

3.3.5 Opening the Housing ....................................................................... 27

3.3.6 Grounding the Housing to the Pedestal ........................................... 29

3.3.7 Mounting the Keyboard.................................................................... 31

3.3.8 Mounting the Scanner Holder to the AG1 Housing .......................... 33

3.3.9 nstalling the Handheld 1-D/2-D Code Reader................................. 37

3.4 Repla ing a VisuNet EX1 with the 19-In h VisuNet GXP.......................... 43

3.4.1 Removing VisuNet EX1 from AG1 Housing...................................... 44

3.4.2 nstalling VisuNet GXP into AG1 Housing ........................................ 46

3.5 Panel Mount Installation ............................................................................. 49

3.6 Wall Mount Installation................................................................................ 52

4 Appendix .................................................................................................................. 54

4.1 A essories.................................................................................................. 54

4.2 UL Control Drawing ..................................................................................... 55