1. Safety Precautions...................................................................1

..................................................................

2.2.

2.3.

2.4.

2.5.

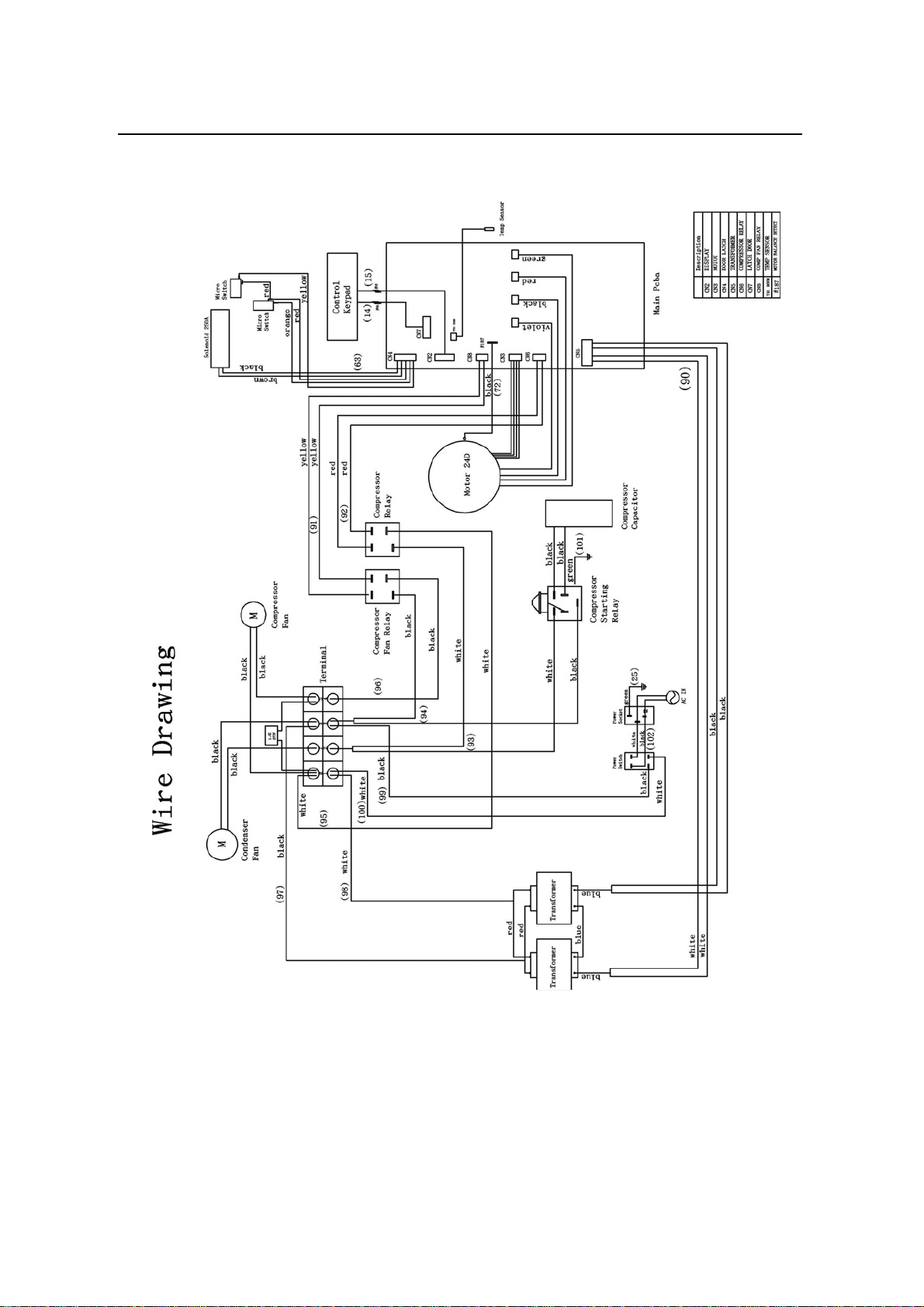

Electrical Component

Specifications...........................................3

PCBs Description

..........................................................................3

Wire Connection Diagrams

..........................................................4

PCBs Connector Location

............................................................6

2.5.1. Power Board PCB’s Connector Locations.............................................

6

2.5.2. Display/MCU Board PCB’s Connector Locations ................................

8

Refrigeration System

....................................................................8

.......................................................................

3.2.

3.3.

Error Messages

............................................................................12

Troubleshooting

Flows

................................................................13

3.3.1. Beeper has no sound

..............................................................................

13

3.3.2. LCD has no display

................................................................................

14

3.3.3. Buttons can’t function

...........................................................................

15

3.3.4. Can’t reach temperature

.......................................................................

16

3.3.5. Can’t reach speed (RPM and RCF) .....................................................

17

3.3.6. Timer can’t count

...................................................................................

17

3.3.7. Lid Lock can’t

release............................................................................

18

3.3.9.

“

” Error (Rotor

Imba

l

ance)..........................................................

20

...................................................

4.2.

4.3.

4.4.

4.5.

4.6.

4.7.

4.8.

4.9.

4.10.

4.11.

Top Case Disassembly

.................................................................24

Main Board

Disassembly

............................................................26

Control PCBA

Disassembly........................................................27

Motor Module

Disassembly........................................................28

Solenoid Module

Disassembly

....................................................29

Condenser Fan Module Disassembly

........................................30

Compressor Fan Disassembly

....................................................31

Transformer Modules Disassembly

...........................................32

Relay & Capacitor Modules

Disassembly.................................33

Power Switch Module Disassembly

...........................................34

i