567

WARRANTY CARD

Electromechanical Lock LB-72.1

Serial number

Date of manufacture ________________ 201__

Quality Control Seal

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Date of sale « » ________________ 201__

____________________________________

(signature, seal)

Cutting line

WARRANTY REPAIR COUPON

.1.27-BLkcoLlacinahcemortcelE

Serial number

Date of manufacture ________________ 201__

Quality Control Seal

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Date of sale « » ________________ 201__

____________________________________

(signature, seal)

Certificate and Operation Manual

www.perco.com

5. MAINTENANCE

6. PERCo WARRANTY

Electromechanical

Mortise Door Lock

- 1.27BL

РОСС RU.СП26.Н

ТУ 4981-049-88226999-2014

03587

6 6 3

6 6 3

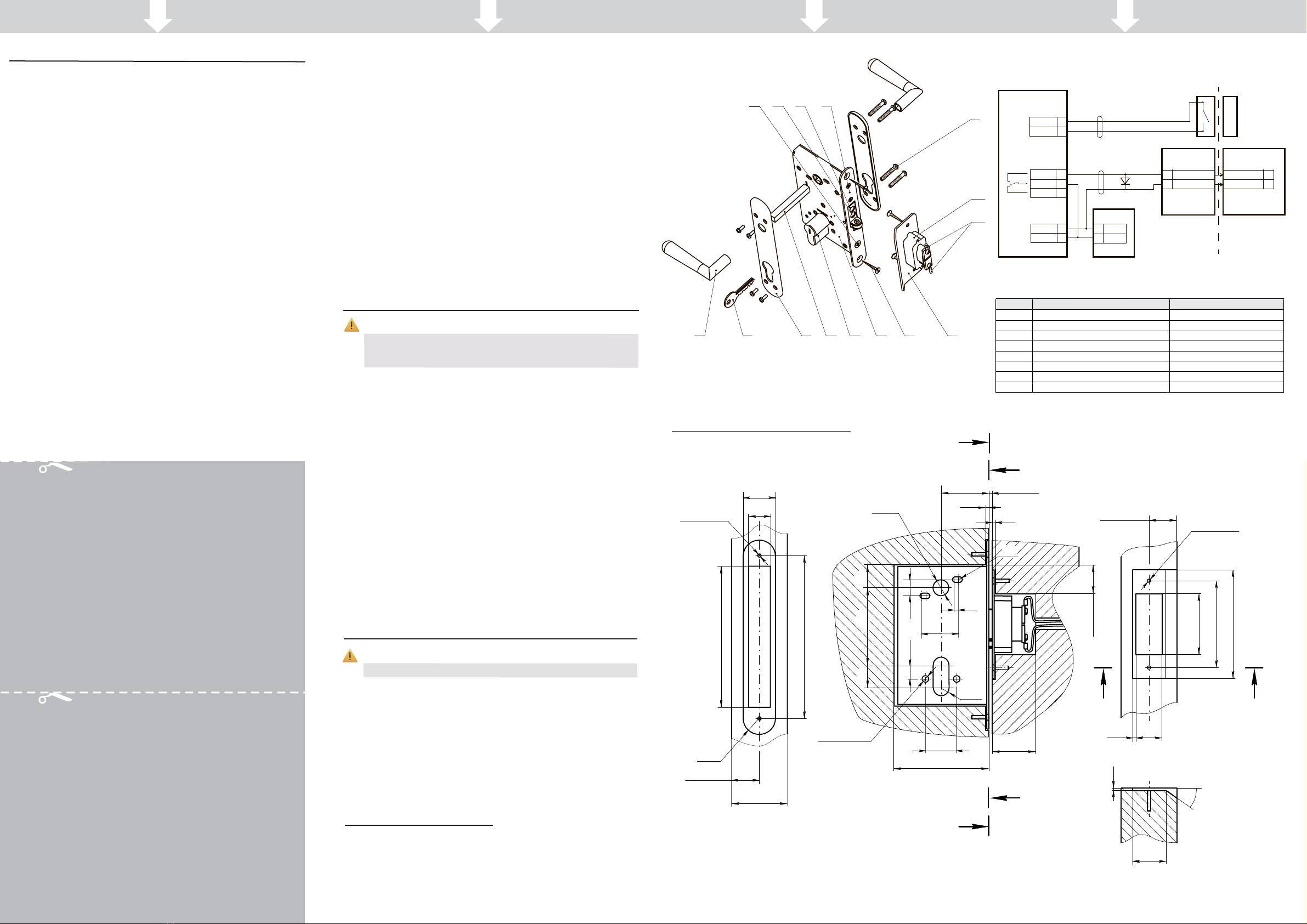

4.3 Installation order

ehttadesuselbaC.1erugiFhtiwecnadroccaninevigerasrebmunecnerefeR

installation are stated in Table 1.

Install the lock in the following order:

1. Unpack the lock and check the delivery set.

2. Carve out the installation template, which is included in the standard

delivery set. Make the hole marking for lock cylinder (6), lever rod (5) and,

if needed, of a location slot for lock forend plate (14) in the door leaf in

the place of lock installation using the template. Template marking

corresponds to the one in Fig. 2.

3. If necessary, select the locating pocket for the lock.

4. Carve out holes and choose the location slot for lock forend plate in

accordance with the marking.

5. Install the lock (7) in the locating pocket of the door and fasten it with two

screws 3.9×25 DIN7982 from the delivery set.

6. Mount the lock cylinder inside the lock and fix it with the screw through

the hole on the lock forend plate.

Attention!

Lock cylinder fastening screw length should not exceed 50 mm.

7. Adjust the door levers (1) with escutcheon plates (4) in accordance with

manufacturer recommendations. Tighten them with the screws with

threaded bushing (3). After the installation levers are to turn easily.

8. Check the lock operation at the opened door.

• Sink the locking mechanism roller (12) inside the lock housing. The bolt

will move out of the lock housing (13). The lock will be closed.

•Insert the key (2) inside the lock cylinder and turn it against stop to check

the mechanical unlocking. The bolt will return into an initial position inside

the lock housing.

• Energize lock flank contacts with 12V power supply to check the auto-

matic unlocking. The bolt will return into an initial position inside the lock

housing.

• Check several times.

9. Fix the strike plate (9) on the terminal block housing (10) with two screws

2.9×13 from the delivery set.

10. Make carving in the door according to the marking (Fig. 2).

11. Lay the control cable from the ACS to the terminal block installation place

inside the door frame. Use cable №1. The cable laying method is deter-

mined by lock installer and the Customer.

12. Connect the control cable with terminal clamps (11) from the terminal

block. In order to do that, tighten cable ends into terminal clamps.

Attention!

If the lock is operated as a part of access control system (ACS) it

is recommended to install voltage regulator diode BZW06-15B or

P6KE16CA, or another model with equal parameters on contact

clips (Fig. 3). The voltage regulator diode is used for maintaining

the device which sends the control signal.

13. Mount the strike plate with the terminal block in the door frame providing

2-3 mm spacing between the strike plate and the forend when the door is

closed. The channel of the strike plate must lay symmetrical to bolt’s cross

section.

Attention!

The locking mechanism roller should not get into the channel of

the strike plate! Otherwise, at closing the door, it can get locked

with the moving roller and then it will be impossible to open the

door without damaging the lock.

14. Mount the strike plate on the door frame with two screws 3.9×25 from the

delivery set.

15. Install and connect the reed switch. Use cable №2 in table 1 for connec-

tion. Installing the reed switch ensure firm contact closure at closing the

door.

Disassembling of the lock should be made in the reverse order.

Warning!

•Do not use the lock at power supply voltage other than specified

in its technical specifications.

• Do not use the lock in operation conditions other than specified

in the following Manual.

•Do not use the lock in hostile environment with atmospheric

content of acids, bases, oils, etc.

The lock is a normally-closed device, which means that in normal condition it

is locked at the closed door. In this case lever turning is blocked. After lock

release the door is opened by turning the lever (approximately at 20º).

Unlocking is performed by:

•Turning the key in the lock cylinder. The key is to be turned against stop

and kept in such a position until the door opens.

•Terminal block clamps’ energizing until the door opens. Energizing is

operated by the ACS controller. At that the potential operation mode

should be set for lock control output. Door opening detection is performed

according to the reed switch status.

At lock release the bolt moves inside the housing and the door can be

opened. At door opening the locking mechanism roller automatically moves

out of the lock housing.

At door closing the locking mechanism roller is sunk into the lock housing,

which initiates bolt moving-out and automatic locking.

PERCo (the Manufacturer) warrants that the LB72.1 electromechanical

mortise door lock (the Product) complies with applicable statutory safety

requirements, electromagnetic compatibility provided that the instructions on

storage, installation and operation, given in the Assembly & Operation Manual

are observed.

The warranty period is 5 (five) years commencing from the date of sale.

Should there be no date of sale on the warranty card, the warranty period

shall commence from the date of manufacture.

Within the warranty period the Product is repaired free of charge at the

Manufacturer’s site.

The Warranty does not cover Products with external mechanical damages or

disassembled by the Customer.

Transportation cost to and back from the place of repair shall be borne by the

Customer.

Upon lock purchase request the date of sale stamp in the warranty certificate

and check the completeness of the delivery set as per the Manual.

In case any questions arise during the Product assembly or operation,

PERCo Company is always ready to give you necessary technical support.

4. ASSEMBLY AND INSTALLATION

4.1 General recommendations

The lock shall be installed by qualified professionals who have studied this

Manual before the installation work.

Attention!

In order to provide stable lock operation an accurate ±1,5 mm

vertical mounting of the strike plate with terminal block

regarding locking bolt is required. The lock operates normally

if the spacing between the forend plate and the strike plate is

2.5±1.5 mm.

4.2 Cable length

Table 1. Cables used.

№Application Max

length Type of cable An example

of cable

1ACS controller

cable 30m

Twin cable with

0.75 mm

cross-section

2HO3VV-F,

HO5VV-F 2×0.75

2Reed switch

cable 30m

Twin cable with

0.2 mm

cross-section

2

RAMCRO

SS22AF-T

2×0.22 or CQR-2

PERCo

Polytechnicheskaya str., 4, block 2

194021, Saint Petersburg

Russia

Tel: +7 812 247 04 64

www.perco.com