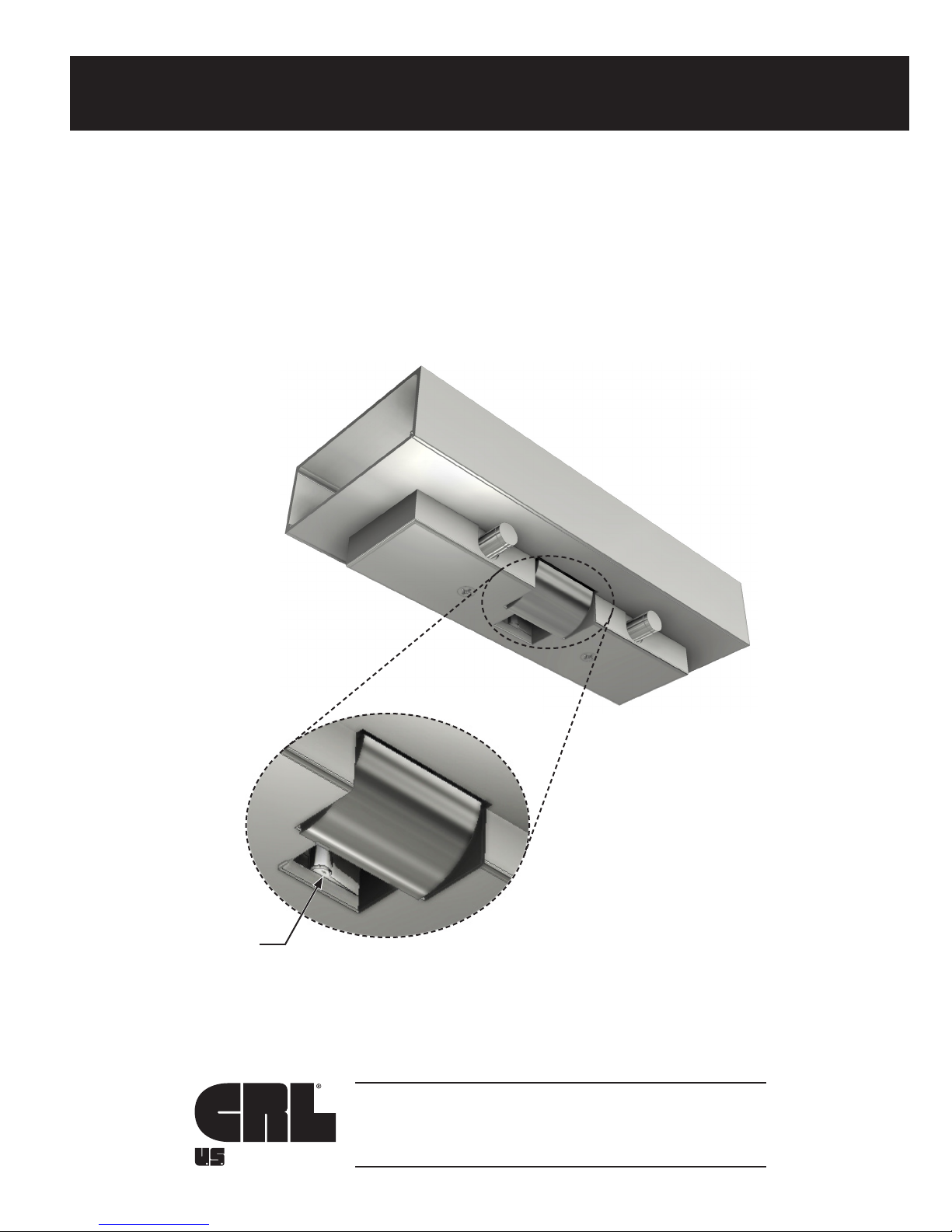

CRL ESK1/ESP1 - ELECTRIC STRIKE KEEPER FOR SINGLE DOORS

03

crlaurence.com | usalum.com

INTRODUCTION

ESK1/ESP1 ELECTRIC STRIKE KEEPER

•Designed for use with 1/2" or 3/4" (12.7 or 19) tempered glass doors.

• Used in conjunction with CRL glass door Panic and Deadbolt Handles.

• Fail secure. (Fail safe optional)

• Latch/Deadbolt Monitor (ESP Strikes only)

This Electric Strike Keeper satises the following safety standards:

a. American National Standards Institute (ANSI/BHMA)

i. A117.1 Providing Accessibility and Usability for Physically Handicapped People

ii. A156.3 Exit Devices

iii. A156.18 Materials and Finishes

b. Americans with Disabilities Act (A.D.A.)

c. American Society for Testing and Materials (ASTM)

d. National Fire Protection Association (NFPA 101)

e. Underwriters Laboratory (UL)

i. 305 Panic Hardware

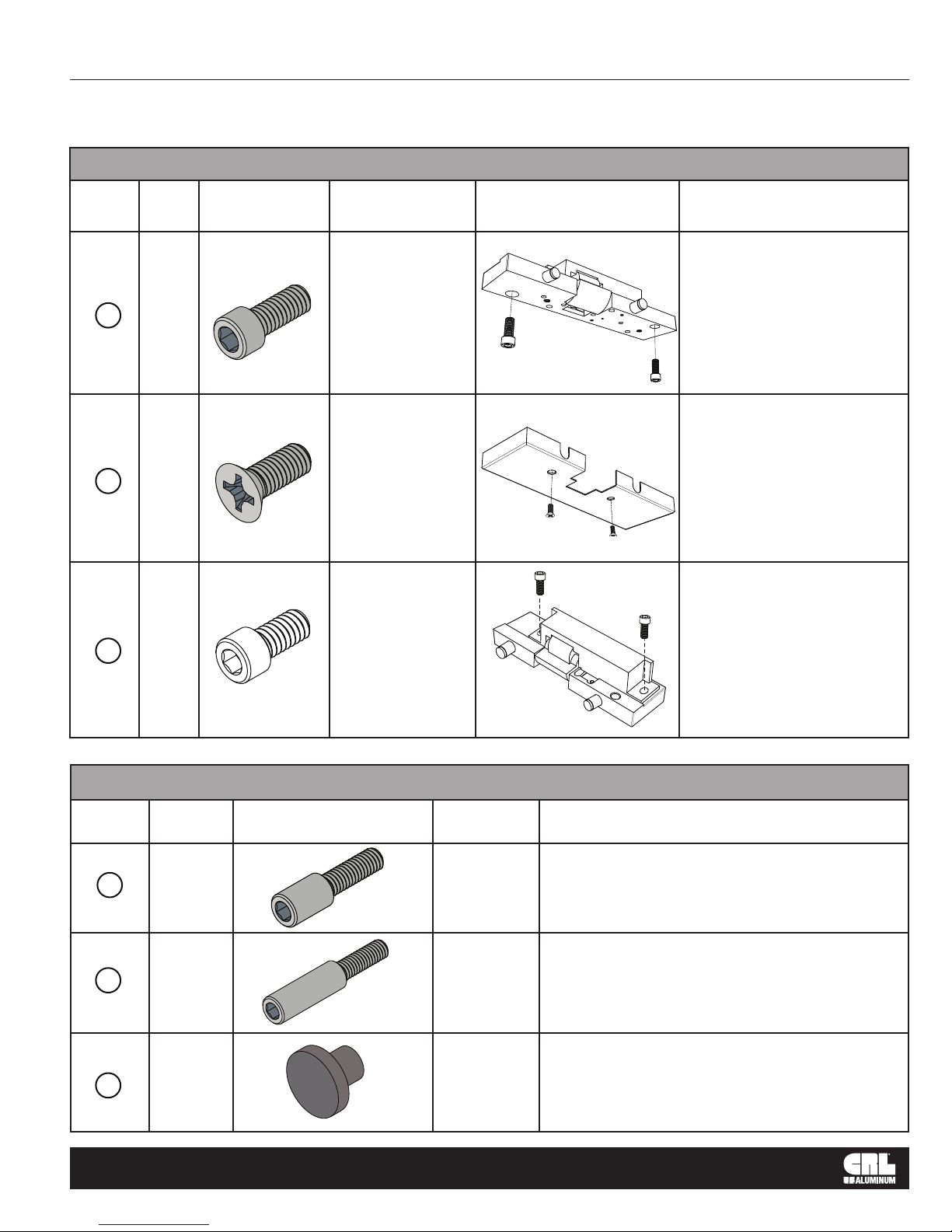

Tools Required

Drill bits: 1/4"

Taps: 5/16-18

Tape Measure

Saw Horses

Cordless Drill

Phillips Head Screwdriver

1/4" and 3/16" Hex Keys

3/4" Masking Tape

Center Punch

Flat Metal File

Round Metal File

Jigsaw with Metal Cutting Blade

Stepladder

Framing Square/Straight Edge

ESP040 Adjustable Gauge (Ordered Separately)

FEATURES

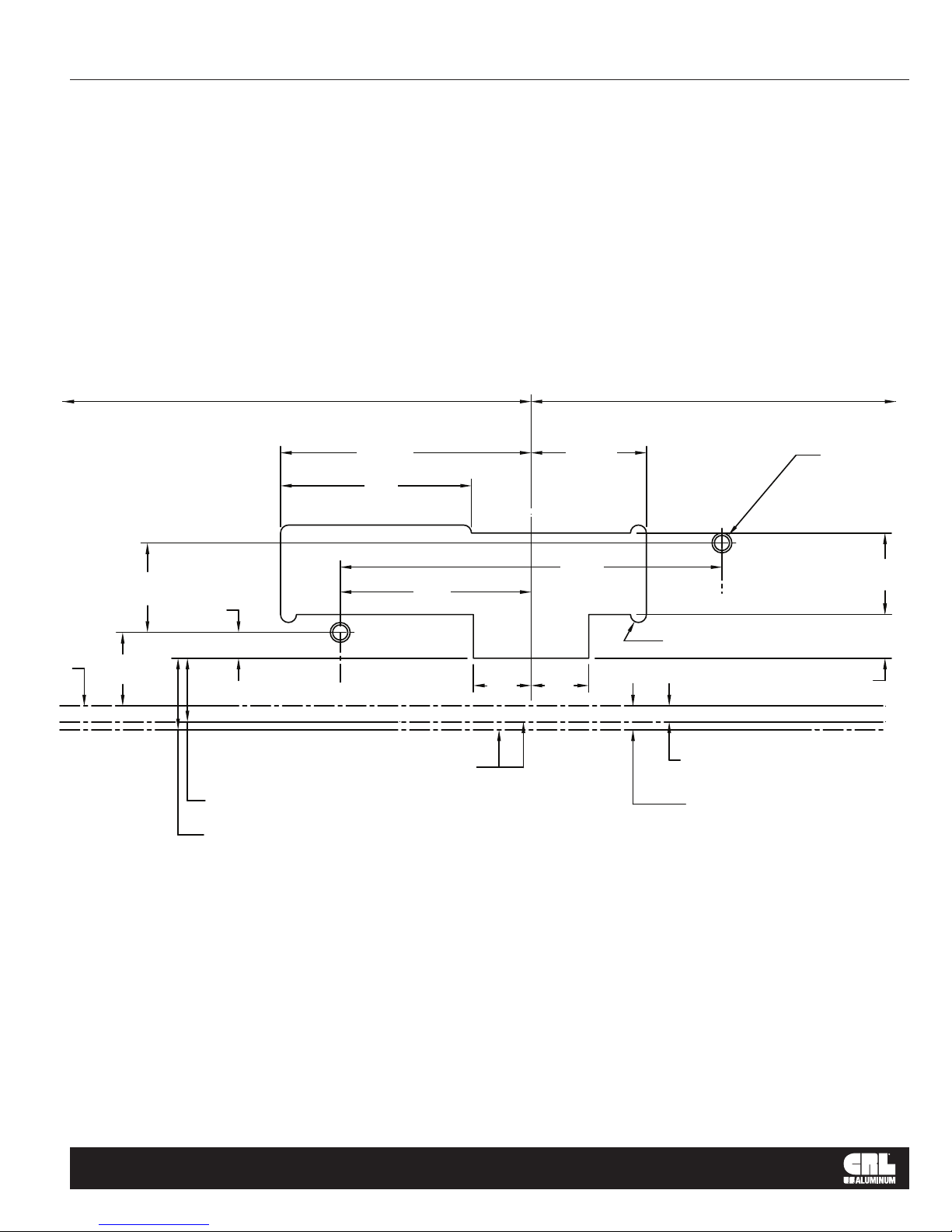

NOTE: Any modications, other than those specied in this document, could result in this product's failure

to meet UL safety ratings and void the manufacturer's warranties.