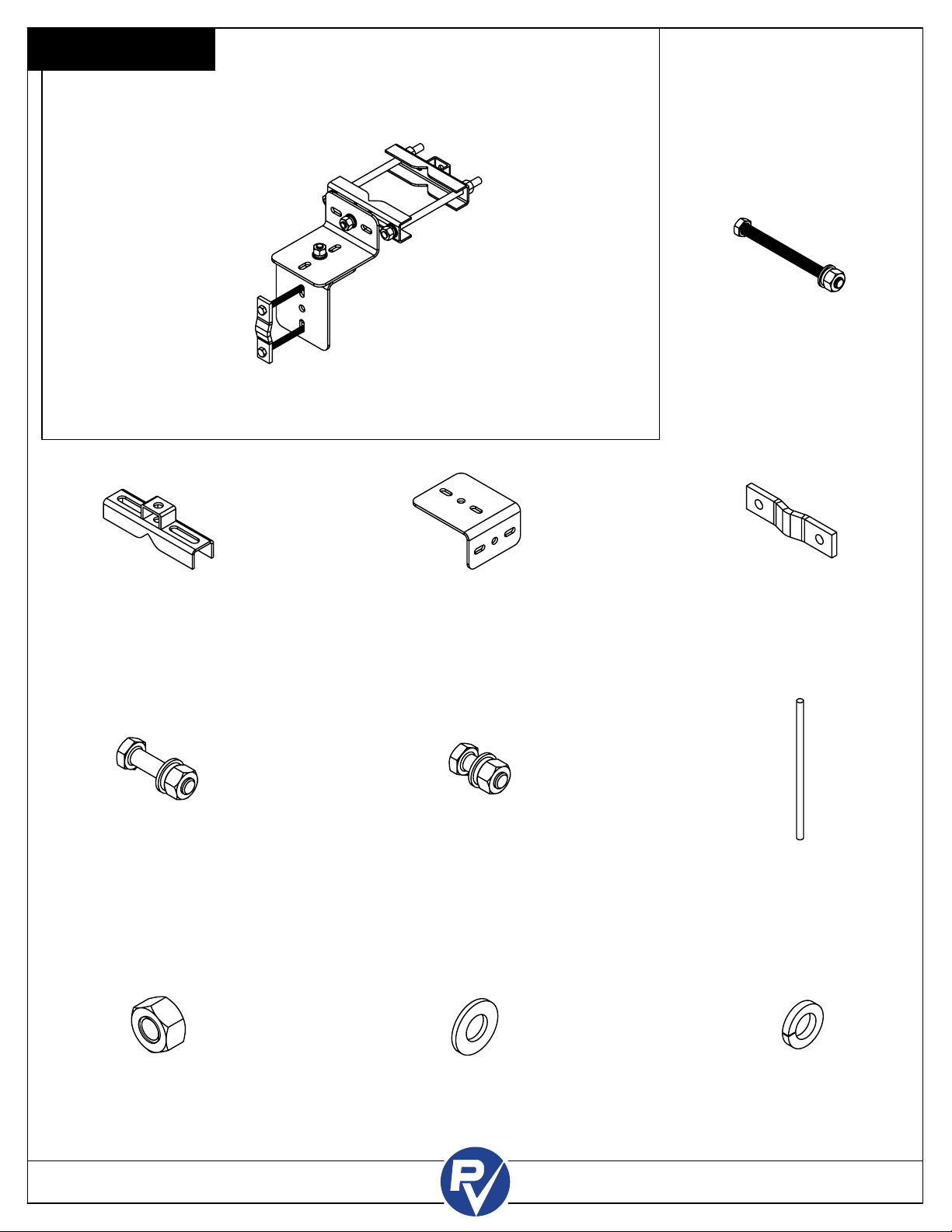

3/8"

3/8"

4 1/2"

1"

1. Supplied Parts List

.........................................................................................................

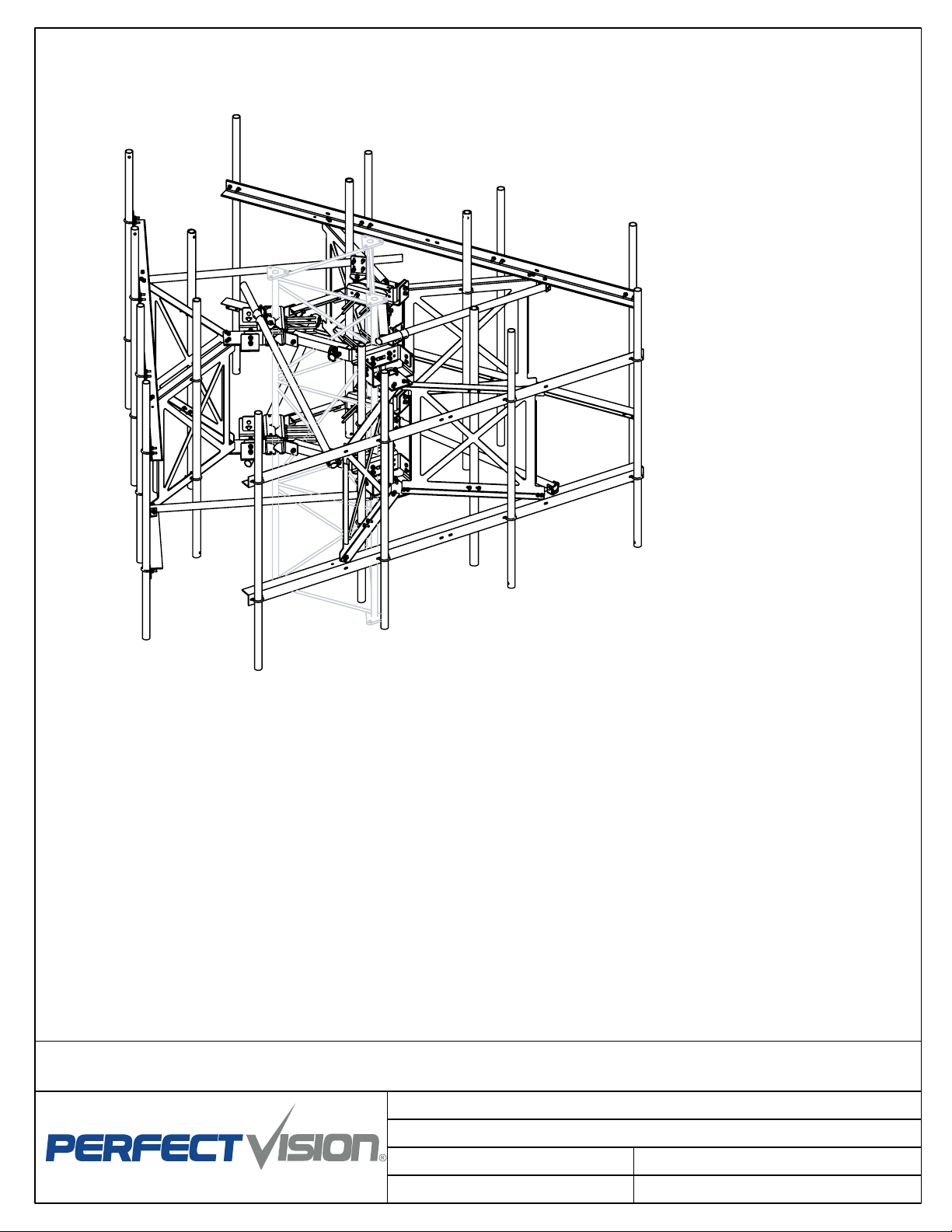

PV-SFA-B Configurations & Part list

.........................................................................3

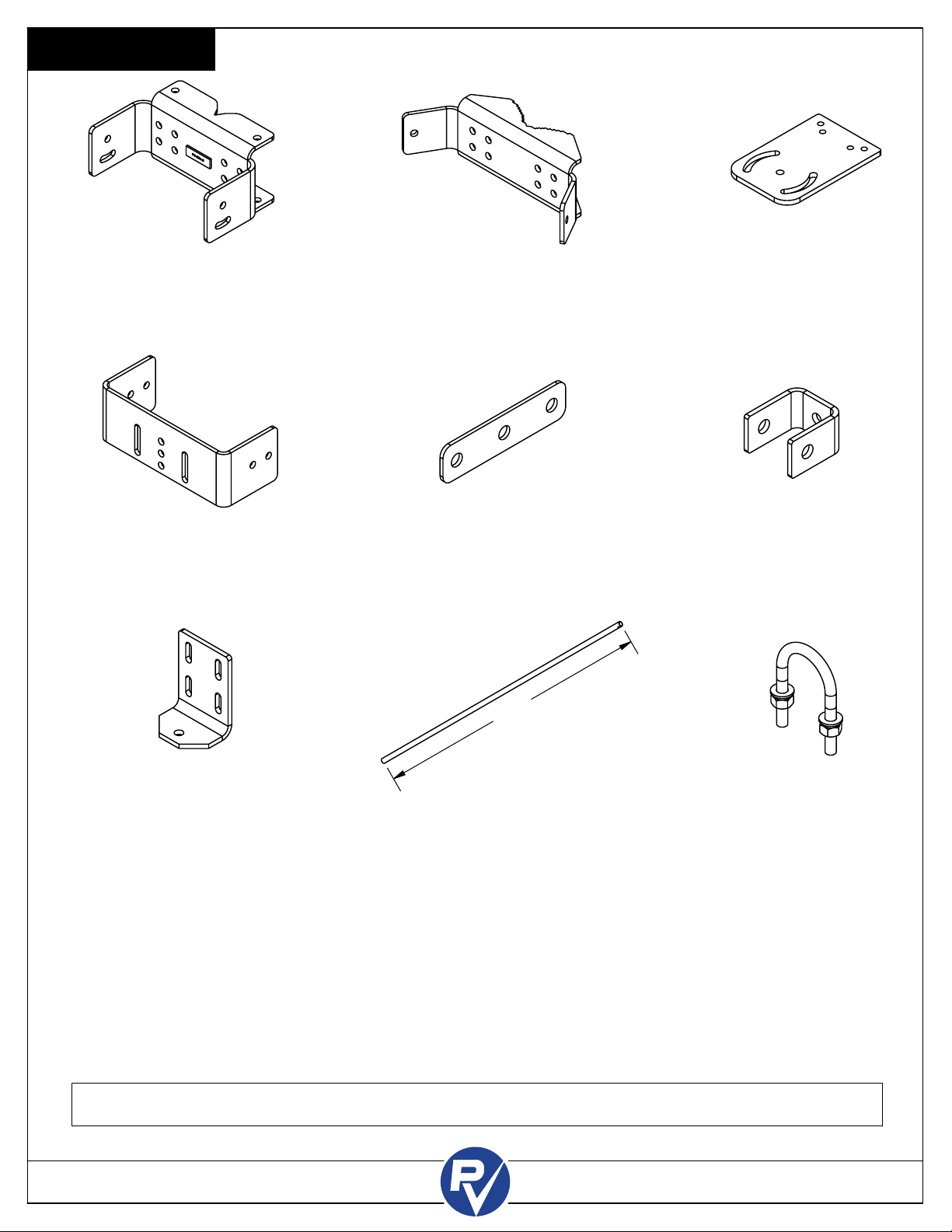

PV-SFA-B Single Sector Parts List

............................................................................4

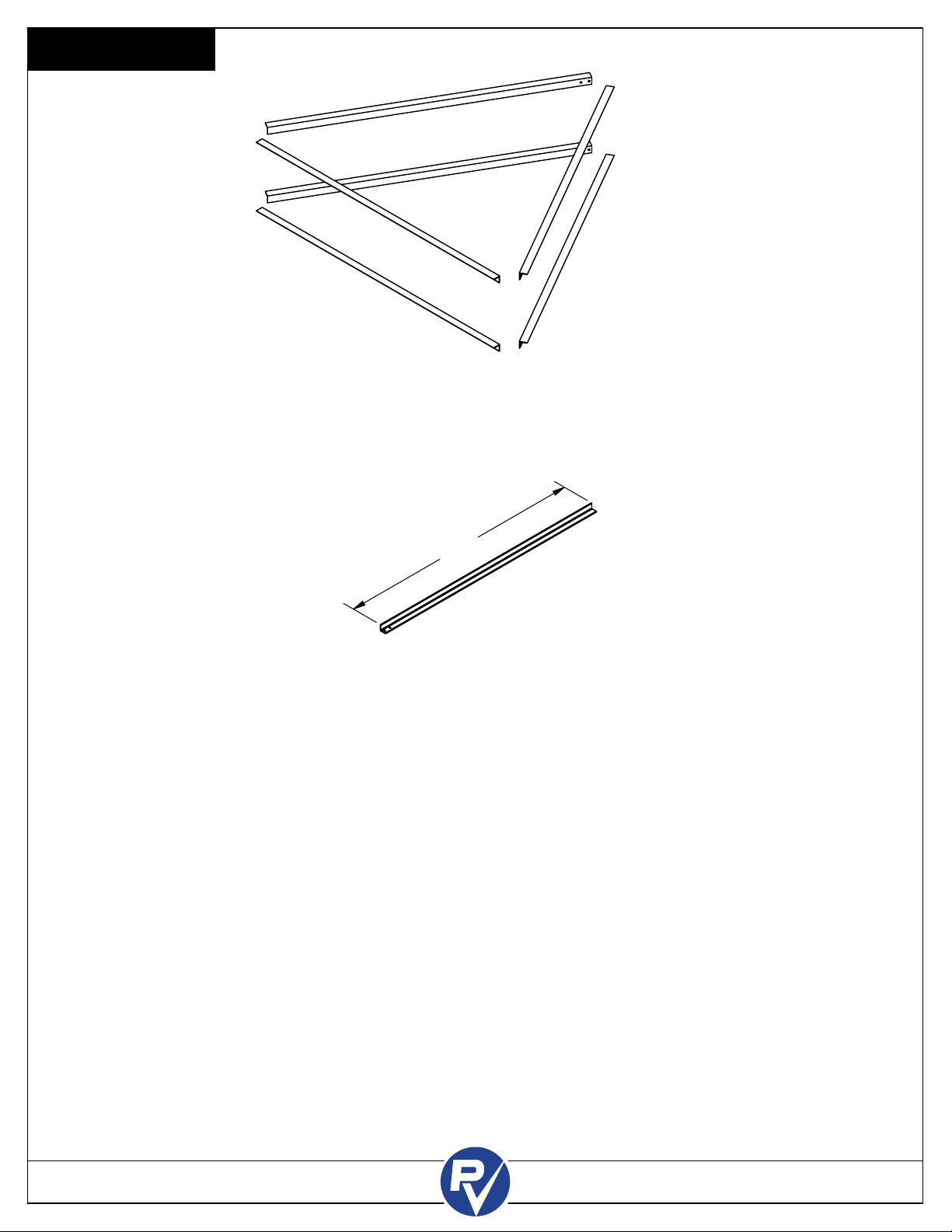

PV-SFA-B Single Sector Parts List Cont'....................................................................5

Additional Parts List................................................................................................6

Optional Stiff Arm Leg Bracket Parts list (For Single Sector installation)......................7

2. Installation Steps

...........................................................................................................

Pre-Assembling Sector Frame..................................................................................8

Pre-Assembling Sector Frame cont'..........................................................................9

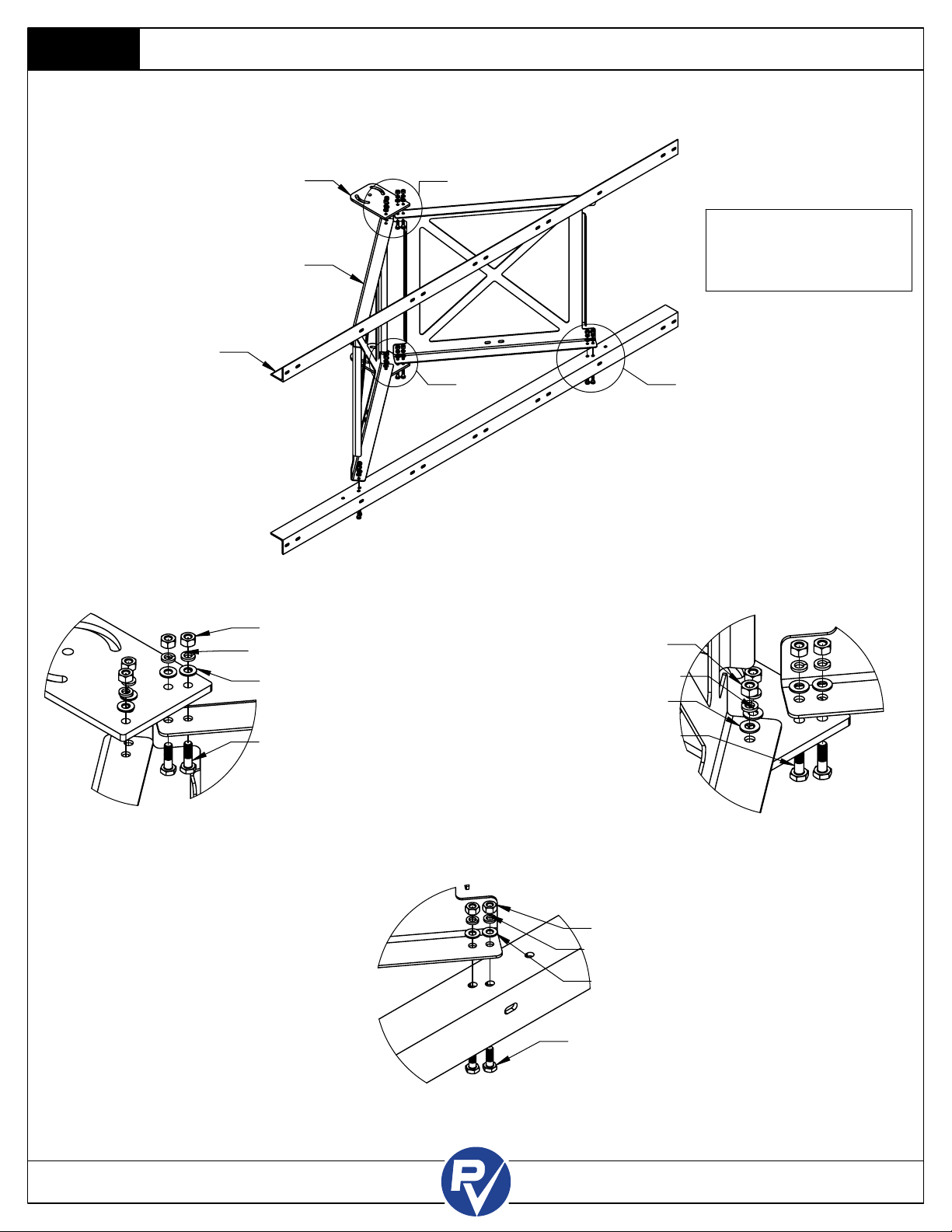

Pre-Assembling Sector Frame & Installing Frame to Tower Leg..................................10

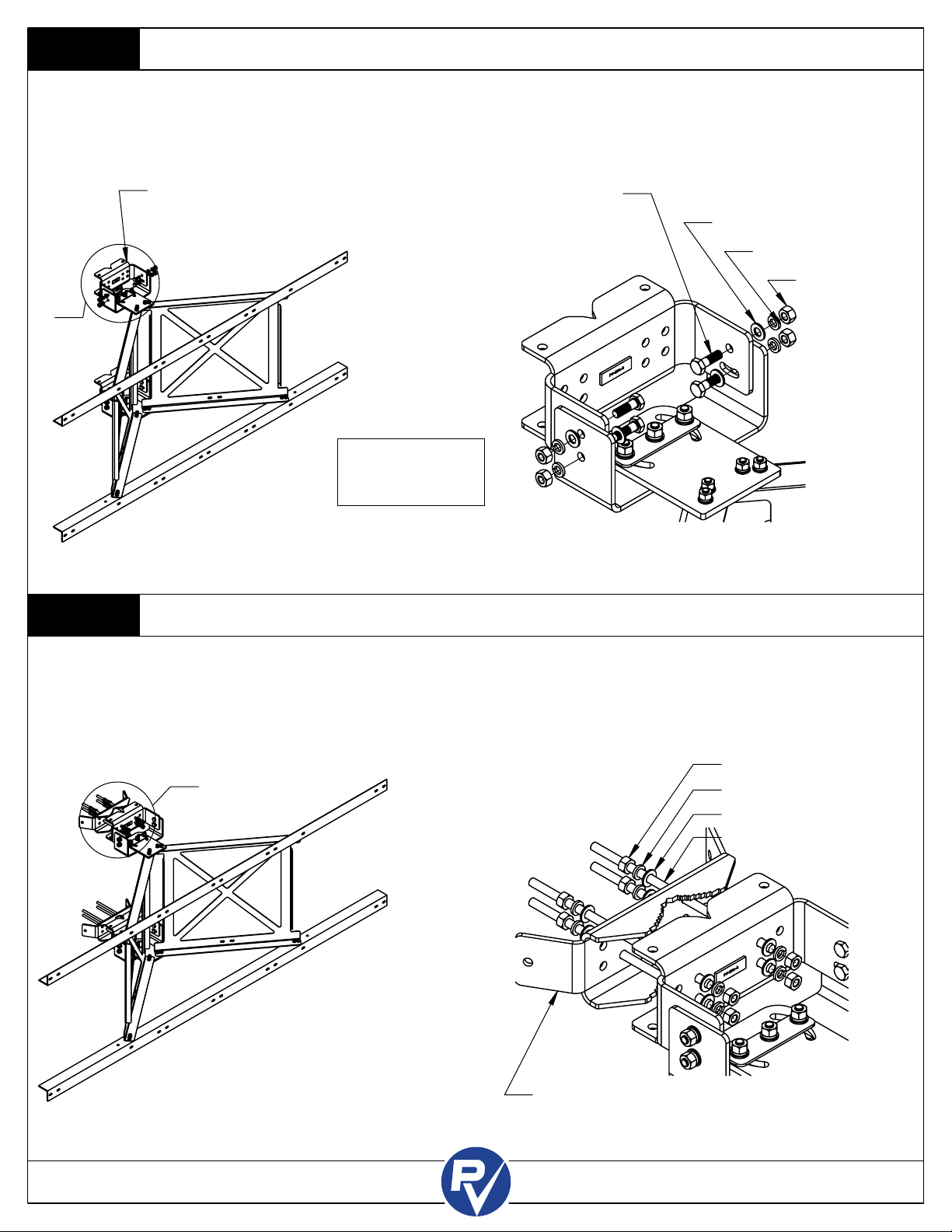

Pre-Assembling Sector Frame & Installing Frame to Tower Leg cont'..........................11

Installing Tie Back Pipes (3 Sector Installation).........................................................12

Installing Tie Back Pipes (Single Sector Installation)..................................................13

Installing Horizontal Angle Kit & Anchors..................................................................14

Installing Antenna Pipe

...........................................................................................15

3. Reference Pages

.............................................................................................................

Safety Climb Routing

..............................................................................................16

Safety Climb Routing cont'

......................................................................................17

Mount Classification Identification............................................................................18

Mount Classification Identification Cont'

...................................................................19

Mount Classification Identification for Dual Collars

....................................................20

TABLE OF CONTENTS

www.perfect-vision.com

PV-SFA-INS-01-R6

1-844-887-6723

2 OF 20