Instruction manual for use and maintenance

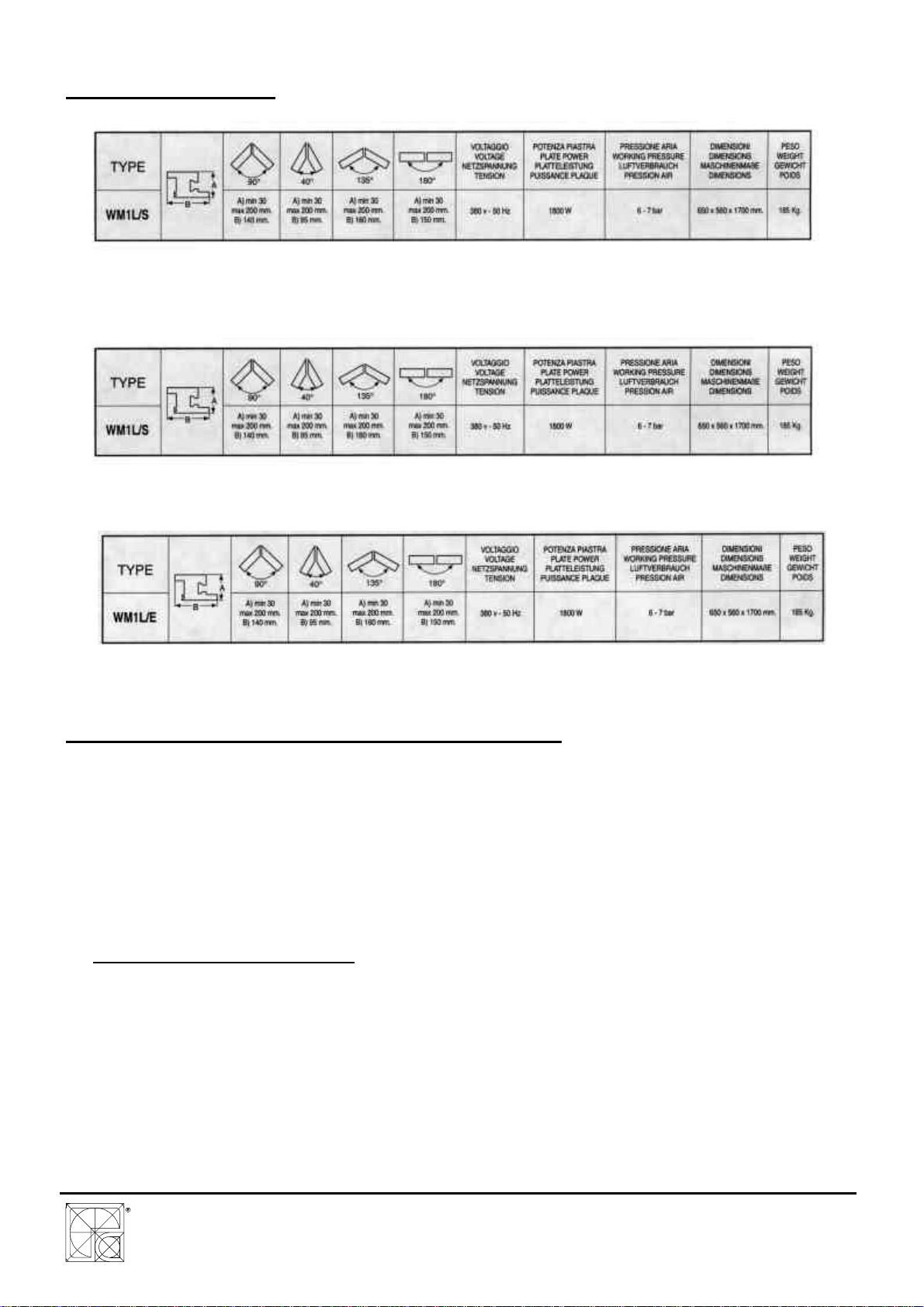

for WM1L/S WM1L/S-M WM1L/E Single

head machines

File: 1927.doc -25/01/02 11:55

2

TABLE OF CONTENTS

TABLE OF CONTENTS .......................................................................................................... 2

1. INTRODUCTION................................................................................................................. 3

2. GENERAL PRECAUTIONS................................................................................................. 3

3. CHARACTERISTICS........................................................................................................... 5

3.1 Description of the machine..................................................................................... 5

3.2 Technical features.................................................................................................. 9

3.3 Directly functioning components during welding .................................................... 9

3.3.1 Heating plate for fusion............................................................................ 9

3.3.2 Welding seal limitation blades ................................................................. 10

3.4 Use limits................................................................................................................ 12

3.4 Standard kits........................................................................................................... 12

3.5 Optional/Spare parts............................................................................................... 13

3.6 Conformity with safety standards............................................................................ 13

4. COMMISSIONING............................................................................................................... 14

4.1 Transport ................................................................................................................ 14

4.2 Positioning.............................................................................................................. 14

4.3 Safety zones and dimensions................................................................................. 15

4.4 Setting up for work.................................................................................................. 15

4.5 Compressed air circuit hook-up.............................................................................. 18

4.6 Connection of the electric equipment.....................................................................18

5. USE..................................................................................................................................... 19

5.1 Checks before use.................................................................................................. 19

5.2 Description of controls............................................................................................ 19

5.3 Operating cycle....................................................................................................... 22

5.4 Emergency device..................................................................................................25

5.5 Functionality of sensors.......................................................................................... 25

5.5.1 Inductive sensor........................................................................................ 25

5.5.2 Reed sensors............................................................................................ 26

5.5.3 Thermocouples ......................................................................................... 26

5.5.4 Welding at anlges different from 90°......................................................... 26

5.6 Precautions to ensure safety during use................................................................27

6. ADJUSTMENT OF WORKING PARAMETERS..................................................................28

6.1 Temperature of the heating plate ...........................................................................28

6.2 Temperature of welding seal limitaton blades (if installed)..................................... 29

6.3 Timer for warming-up.............................................................................................. 29

6.4 Cooling Timer.........................................................................................................30

6.5 Mechanical parameters for welding........................................................................ 30

SERVIZI .................................................................................................................................. 32

9.1 –PLATE CLEANING.............................................................................................. 32

9.2 –REPLACEMENT OF TEFLON.............................................................................. 33

9.3 –PROTECTED MENU ........................................................................................... 34

9.4 –RESET MEMORY................................................................................................ 34