Contents

Contents Page

9Preparation .......................................................................................................................................... 20

9.01 Adjusting the feed roller clearance (roller gap)...................................................................................... 20

9.02 Selecting the sealing mode and the pedal mode .................................................................................. 21

9.03 Secondary feed rollers .......................................................................................................................... 22

10 Sealing ................................................................................................................................................. 23

10.01 Sealing principle.................................................................................................................................... 23

10.02 Sealing modes ...................................................................................................................................... 23

10.02.01 Standard sealing with specified amplitude (amplitude sealing) ............................................................. 24

10.02.02 Standard sealing with specified power (power sealing)......................................................................... 25

10.02.03 Dynamic sealing with specified amplitude............................................................................................. 27

10.02.04 Dynamic sealing with specified power................................................................................................... 28

10.02.05 Basting .................................................................................................................................................. 29

10.03 Sealing formulas ................................................................................................................................... 30

11 Input ..................................................................................................................................................... 31

11.01 Main menu input ................................................................................................................................... 31

11.02 Data management................................................................................................................................. 32

11.03 Settings menu ....................................................................................................................................... 33

11.04 Service menu ........................................................................................................................................ 34

11.05 Blocking the feed roller.......................................................................................................................... 35

11.06 Setting feed roller parameters............................................................................................................... 36

11.07 Setting the neutral point of the feed roller ............................................................................................. 37

11.08 PIN code menu ..................................................................................................................................... 38

11.09 Adjusting the clock time ........................................................................................................................ 40

11.10 Adjusting the current of the drive motors............................................................................................... 41

11.11 Setting the machine configuration......................................................................................................... 42

11.12 Changing the contrast of the control panel display ............................................................................... 43

11.13 Rental menu.......................................................................................................................................... 44

12 Maintenance and self help ................................................................................................................. 45

12.01 Cleaning and care................................................................................................................................. 45

12.02 Protective switch ................................................................................................................................... 45

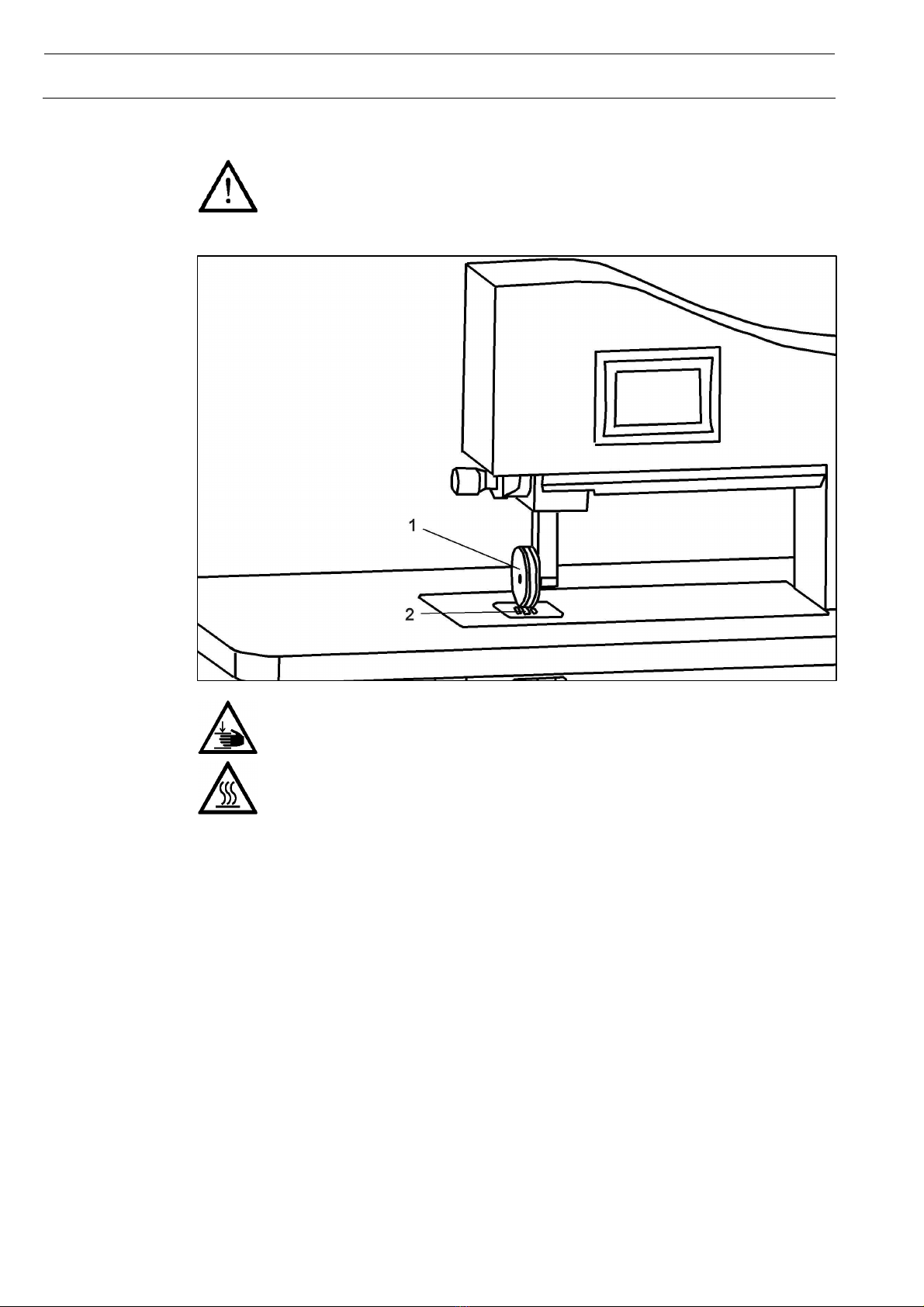

12.03 Changing feed roller.............................................................................................................................. 46

12.04 Error messages..................................................................................................................................... 47

12.05 Circuit diagrams .................................................................................................................................... 48