Page 1aPage 1b

DONNEES TECHNIQUES DE LA MACHINE

1. ATTENTION: Afin de garantir un fonctionnement en toute sécurité, cette machine

doit être installée et entretenue par un technicien agréé.

2. ATTENTION: Si le couvercle ou le mécanisme de blocage de sécurité est endom-

magé, ne pas utiliser la machine tant que les réparations n’ont pas été

effectuées.

3. ATTENTION: Cette machine doit être raccordée à la terre. Les fils de couleur du

câble d’alimentation sont:

110-120V 220-240V Connecté:

Vert Vert/Jaune à la terre (masse).

Blanc Bleu au neutre.

Noir Brun à la tension.

4. ATTENTION: Cette machine ne doit pas être utilisée si le câble d’alimentation est

endommagé. Il y a lieu de le remplacer par un câble similaire:

UK N° de pièce 162-210

EURO N° de pièce 162-311

US N° de pièce 162-321

5. ATTENTION: Pour ne pas compromettre la protection contre les risques d’incendie,

remplacer par un fusible de même type at de mêmes caractéristiques

nominales:

110-120V T6.3A 250V N° de pièce 135-106

220-240V T3.15A 250V N° de pièce 135-103

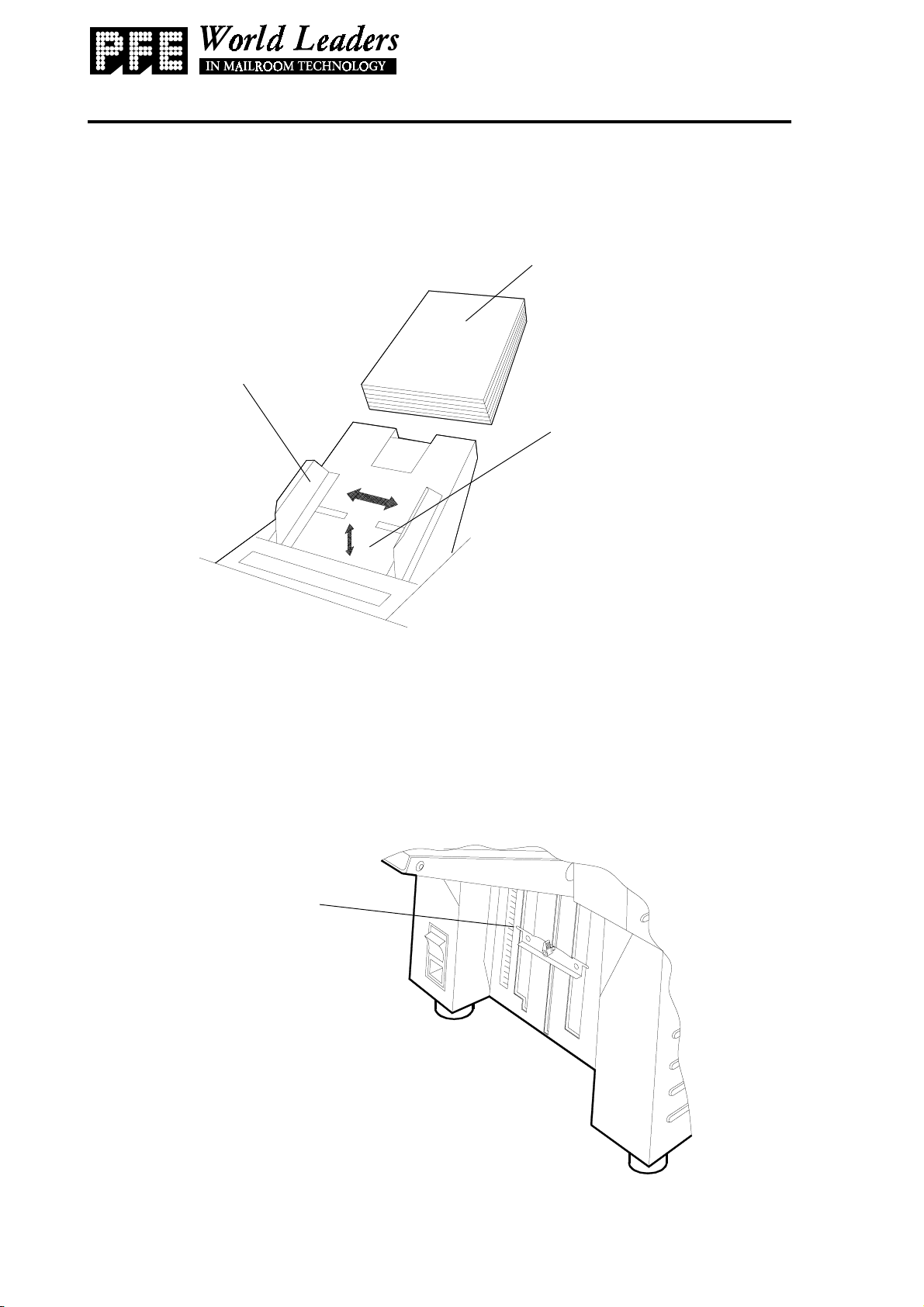

6. Spécifications: Nom du modèle: Desktop Pressure Sealer

Numéro du modèle: 4040/4060

Tension d’entrée: 110-120V à 60Hz 220-240V à 50 Hz

Courant d’entrée: 3A 1,5A

Puissance d’entrée: 360W 360W

Niveau de bruit: 75 dBA75 dBA

(mesuré en insérant un seule feuille dans une enveloppe à une distance

de 1 mètre du capot le plus proche et à 1,6 mètre du sol).

Poids: 72kg (158lbs) déballée

Le levage ou la manipulation de la machine ne peut être effectué que par des personnes quali-

fiées utilisant l’outillage approprié.

7. Cette machine est conçue tout spécialement pour fermer avec la pression les documents.

Issue 1 Apr 2002