Table of contents

Revision 4 | Operating instructions temperature measuring probe GT 1 3 | 20

1Introduction ..............................................................................................................4

Designated use ...................................................................................................... 4

Declaration of Conformity ..................................................................................... 5

Structural features of the danger notes ................................................................ 6

Pictograms in the operating instructions............................................................... 6

2Safety........................................................................................................................7

3Technical data ...........................................................................................................8

Dimensions ............................................................................................................ 8

Weight ................................................................................................................... 8

Power supply ......................................................................................................... 8

General data .......................................................................................................... 8

4Delivery, transport and storage.................................................................................9

Scope of delivery ................................................................................................... 9

Transport and packaging ....................................................................................... 9

Intermediate storage............................................................................................. 9

Return transport.................................................................................................... 9

5Operation................................................................................................................10

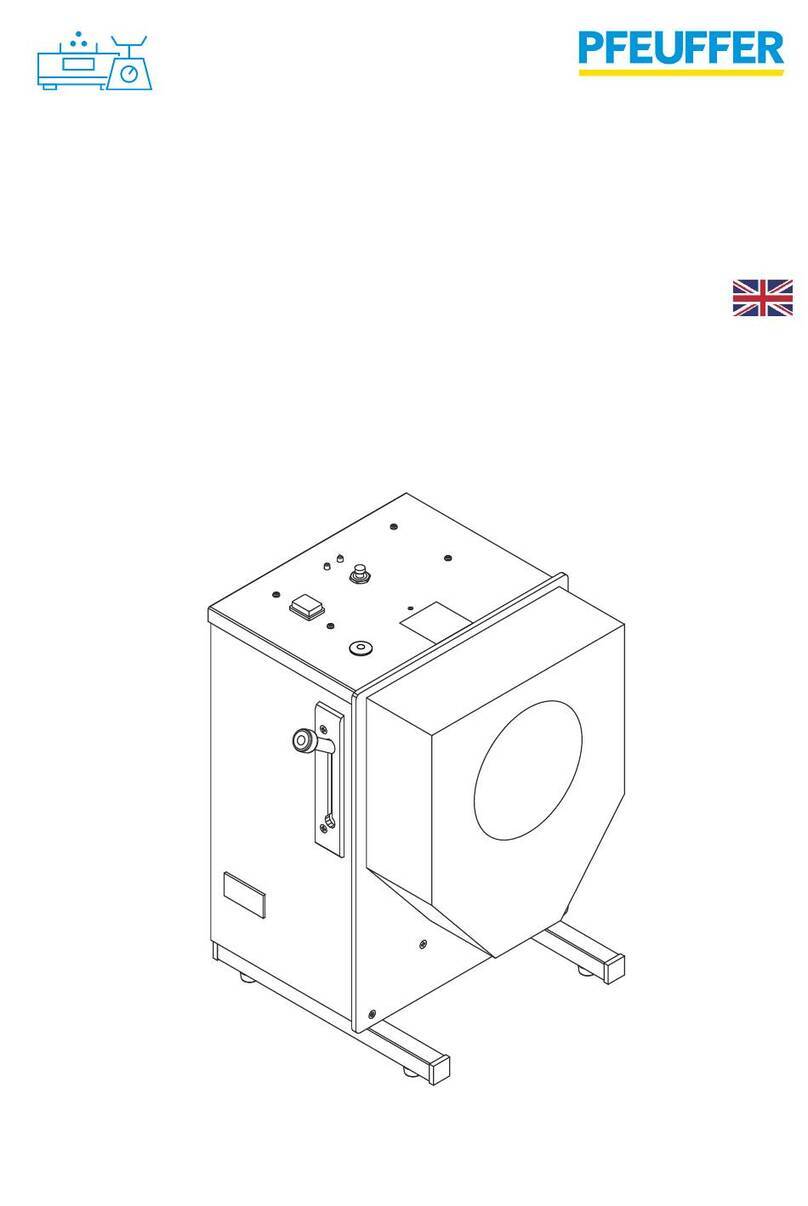

Overview.............................................................................................................. 10

Insert and change battery.................................................................................... 10

Display modes...................................................................................................... 11

MAX / MIN memory............................................................................................. 12

Setting the time ................................................................................................... 13

Switching off the GT 1.......................................................................................... 13

Perfroming measurements.................................................................................. 14

5.7.1 Measure haystack.................................................................................... 14

5.7.2 Influence of moisture and storage temperature on the shelf life of grain .... 16

5.7.3 Monitoring of grain stocks is essential..................................................... 17

Measurement uncertainty................................................................................... 17

6Cleaning and maintenance ......................................................................................18

Cleaning ............................................................................................................... 18

Maintenance........................................................................................................ 18

7Malfunctions – causes and rectification...................................................................19

8Spare parts..............................................................................................................19

9Disposal...................................................................................................................19

Measurement table for haystack ...........................................................................20