Revision 3 | Granolyser / Granolyser HL operating instructions

1Introduction ............................................................................................................................ 5

1.1 Designated use................................................................................................................................... 5

1.2 Declaration of Conformity ................................................................................................................. 6

1.3 Structural features of the danger notes ............................................................................................ 7

1.4 Pictograms in the operating instructions........................................................................................... 8

1.5 Identification...................................................................................................................................... 8

2Safety ......................................................................................................................................9

2.1 Built-in safety systems ....................................................................................................................... 9

2.2 Electrical connections ...................................................................................................................... 10

2.3 Connecting USB devices................................................................................................................... 10

2.4 Operating and danger areas on the GRANOLYSER .............................................................................. 10

2.5 Operating and maintenance personnel ........................................................................................... 11

2.6 Safety measures (to be carried out by the owner) .......................................................................... 11

2.7 General safety notes ........................................................................................................................ 12

2.8 Safety tests....................................................................................................................................... 13

2.9 Residual dangers in connection with the GRANOLYSER...................................................................... 13

2.10 Switch-off procedure ....................................................................................................................... 13

3Technical data ....................................................................................................................... 14

3.1 Dimensions and weight.................................................................................................................... 14

3.2 Power supply.................................................................................................................................... 14

3.3 General data..................................................................................................................................... 14

4Delivery, transport and storage .............................................................................................. 15

4.1 Scope of delivery.............................................................................................................................. 15

4.2 Transport and packaging.................................................................................................................. 15

4.3 Intermediate storage ....................................................................................................................... 15

4.4 Transport to the installation site (by the customer)........................................................................ 15

5Installation and commissioning .............................................................................................. 17

6Function ................................................................................................................................ 18

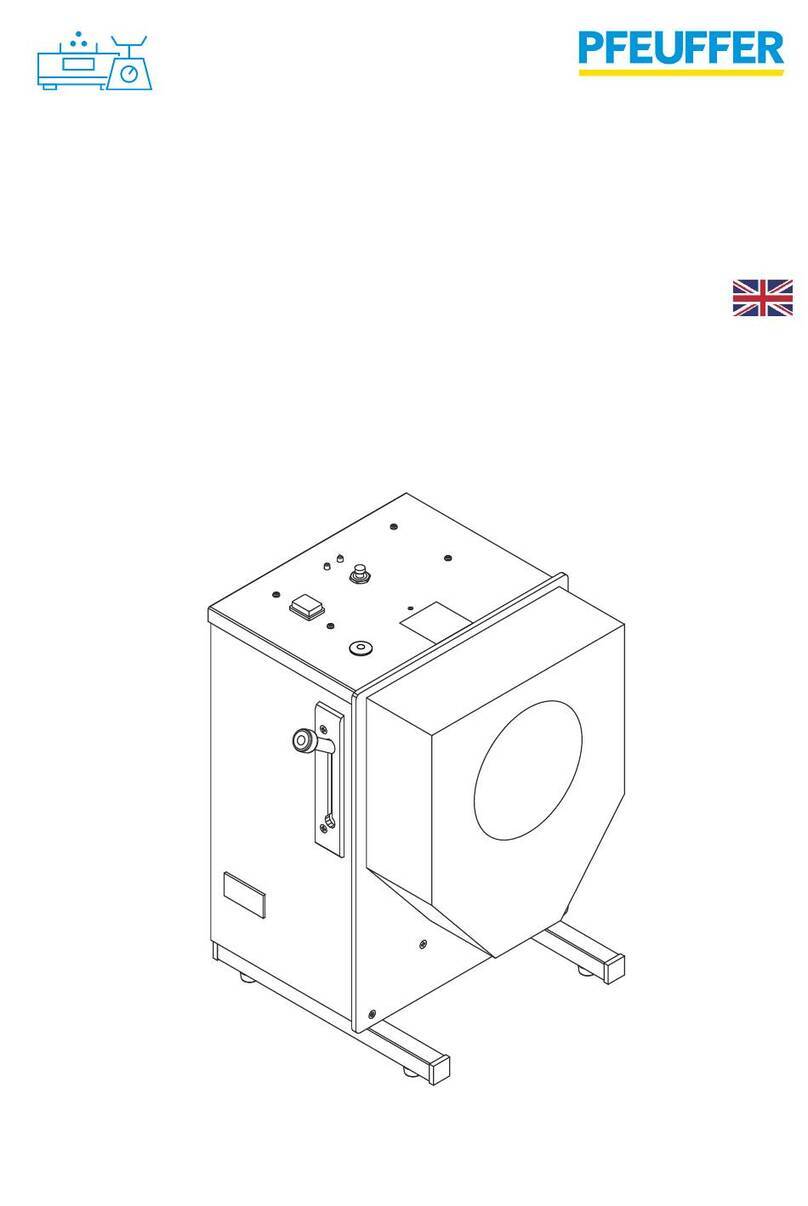

6.1 Components of the GRANOLYSER ....................................................................................................... 18

6.2 Sequence of functions...................................................................................................................... 19

6.3 Reference methods for calibration .................................................................................................. 19

6.4 Products and measuring ranges....................................................................................................... 20

7Operation .............................................................................................................................. 21

7.1 Preparation of a sample................................................................................................................... 21

7.2 Drawer mechanism .......................................................................................................................... 22